Intelligent straw gasification furnace

A gasification furnace, intelligent technology, applied in the field of gasification furnaces, can solve the problems of inability to grasp the timing of its feeding, failure to produce gas by pyrolysis, and high moisture content of straw, so as to improve the gas production effect, reduce the failure rate, and improve The effect of gasification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

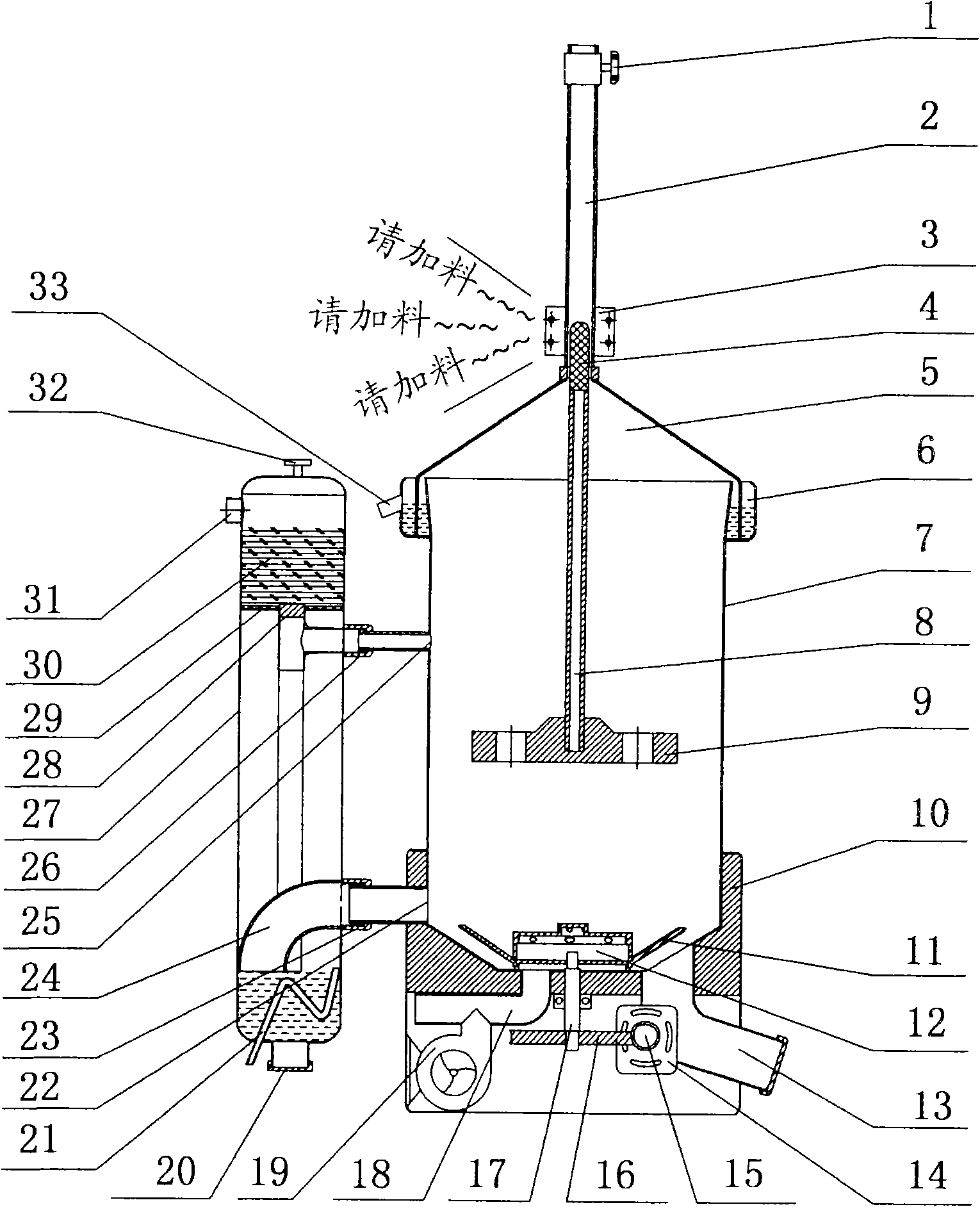

[0013] exist figure 1 Among them, the upper part of the cylindrical furnace body (7) is provided with a conical dehumidification furnace cover (5) with a small upper part and a larger lower part with a certain slope, and its bottom periphery is inserted into an annular water tank (6) arranged around the furnace mouth. An overflow pipe (33) is installed on one side of the annular water tank, and a slightly thicker guide sleeve (2) is arranged upwards in the center of the humidity exhaust furnace cover (5), which can also be used as an exhaust pipe, and an exhaust valve (1) can be arranged on the upper part The lower part can fix the prompter (3) of the built-in magnetic field control switch according to the height set as required, and the guide sleeve is built with a thinner guide post (8) connected to the pressing block (9), and its top is embedded with the magnetic block (4). There should be a gap between the guide sleeve and the guide column to facilitate exhaust. The lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com