Method for improving performance of methane produced by anaerobic reaction on manure

A technology for biogas and human feces production, applied in biological sludge treatment, waste fuel, etc., can solve the problem of anaerobic digestion of a single human feces raw material, achieve the effects of improving biological conversion rate, simple process, and improving gas production performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

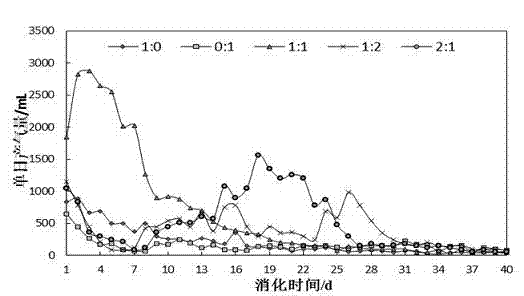

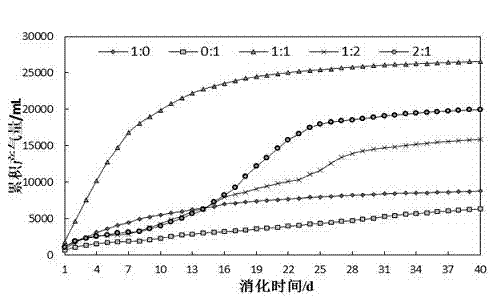

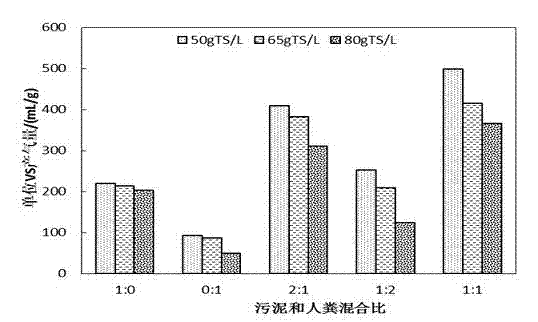

[0019] Biogas production performance of mixed anaerobic digestion of human manure and primary sludge in different proportions:

[0020] The human manure and the primary sludge after centrifugation or sedimentation are in the ratio of 1:0, 1:1, 2:1, 1:2, 0:1 to the total solid mass ratio (wherein 1:0 and 0:1 are respectively Pure sludge and pure human feces) are fully mixed;

[0021] Put the obtained mixed substance into a 2L Erlenmeyer flask anaerobic digestion reactor, inoculate the digested sludge of the sewage treatment plant, and mix thoroughly. 15000mg / L add water to make up to 1.5L working volume;

[0022] Adjust the organic loads of the substances in the reactor to be 50gTS / L, 65gTS / L, and 80gTS / L respectively. At this time, there are 3 loads in total, and each load has 5 ratios. The Erlenmeyer flask anaerobic digestion reactor was closed with a rubber stopper, and the reactor gas outlet was connected to the device for draining and recording gas through a gas pipeline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com