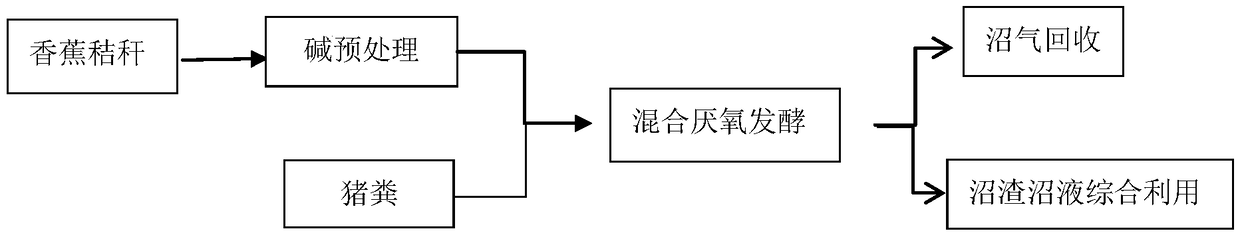

Method for promoting anaerobic fermentation to produce biogas by alkali-pretreated banana straw cooperating with pig manure

A banana straw and alkali pretreatment technology, which is applied in fermentation, biological sludge treatment, waste fuel, etc., can solve the problems of difficult degradation of cellulose, many inhibitory factors, and system instability, so as to increase buffering and stability, Stability of the fermentation system and the effect of increasing biogas production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

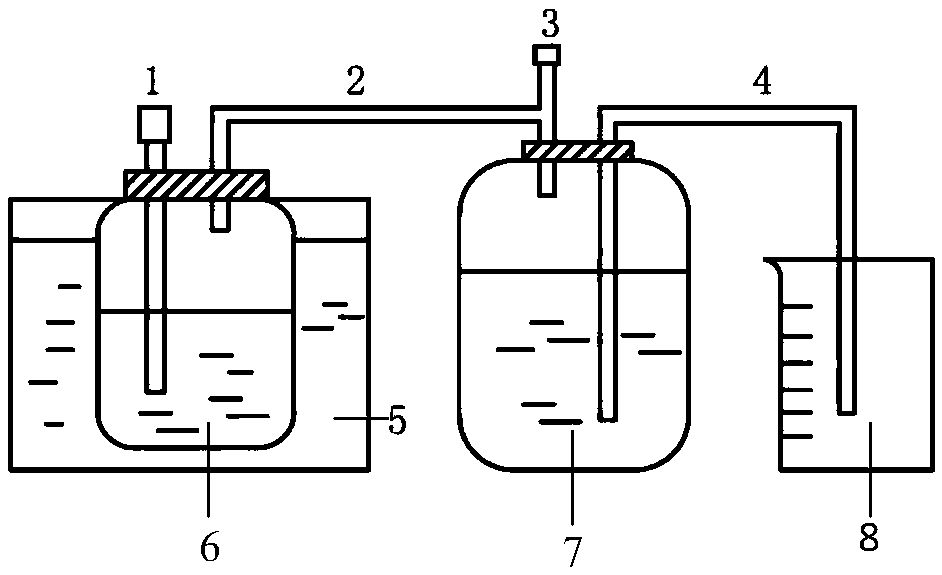

Method used

Image

Examples

Embodiment 1

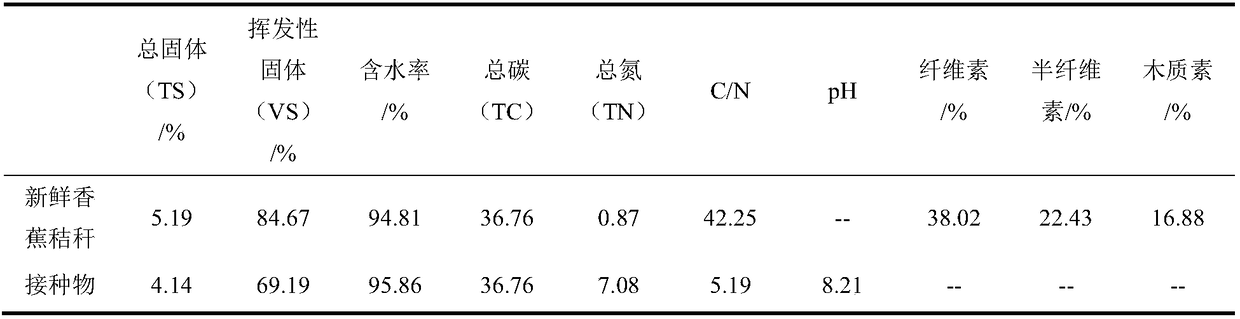

[0025] The characteristics of the banana stalks in the alkali pretreatment stage of the present invention are shown in Table 1-1.

[0026] Table 1-1 Physical and chemical indicators of banana straw and inoculum

[0027]

[0028] Note: % in the table is mass percentage.

[0029] Weigh 150g (dry mass) of 4 groups of banana stalks respectively and place them in a 2000mL beaker, add water at a solid-to-liquid ratio of 1:9, and add 2%, 4%, 6%, 8% NaOH, mix evenly, seal with plastic film and let it stand at room temperature (28±2°C), measure the pH value of the treatment solution every day, measure the COD and VFA of each group of treatment solutions after 7 days, and rinse with a large amount of water Wash the banana straw until the eluent is neutral, measure the TS and VS of the straw, and dry it naturally for later use.

[0030] The above-mentioned NaOH pretreated banana stalks were subjected to anaerobic fermentation, and each treatment group was set with 2 repetitions, and...

Embodiment 2

[0038] The characteristics of the banana straw, pig manure matrix and inoculation mud in the mixed anaerobic fermentation stage of banana straw and pig manure of the present invention are shown in Table 2-1.

[0039] Table 2-1 Physical and chemical indicators of test raw materials

[0040]

[0041] (1) Effects of different ratios of manure and straw on mixed anaerobic fermentation of banana straw and pig manure

[0042] Banana stalks pretreated with NaOH were mixed with fresh pig manure for anaerobic fermentation. In each fermentation bottle, the total solid mass fraction of the fermentation feed liquid was 6% to 7%, and the inoculum concentration was 30% (the inoculum mass accounted for The percentage of the total mass of feed liquid), the quality of pig manure dry matter accounts for 0%, 20%, 35%, 50%, 65%, 80%, 100% of the total mass of banana stalk dry matter and pig manure dry matter, After all the materials are mixed evenly, the total mass of the fermentation feed li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com