Device and method for preparing biological gas and liquid organic fertilizer from fruit and vegetable wastes of collecting and distributing center

A fruit and vegetable waste and liquid organic fertilizer technology, which is applied in the preparation of organic fertilizers, the treatment of bio-organic parts, biochemical equipment and methods, etc., can solve the problems of reduced stirring efficiency, accumulation, and small volume of impurities, so as to avoid entanglement and Effects of destroying, avoiding hardening of raw materials, and improving fermentation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035]The fruit and vegetable waste collected by the Jiangnan Fruit and Vegetable Wholesale Market in Guangzhou is mixed with small impurities such as foam plastics, packaging bags, wide tapes, strapping tapes, sand and gravel, and raw materials with high fiber content such as corn leaves and corn stalks.

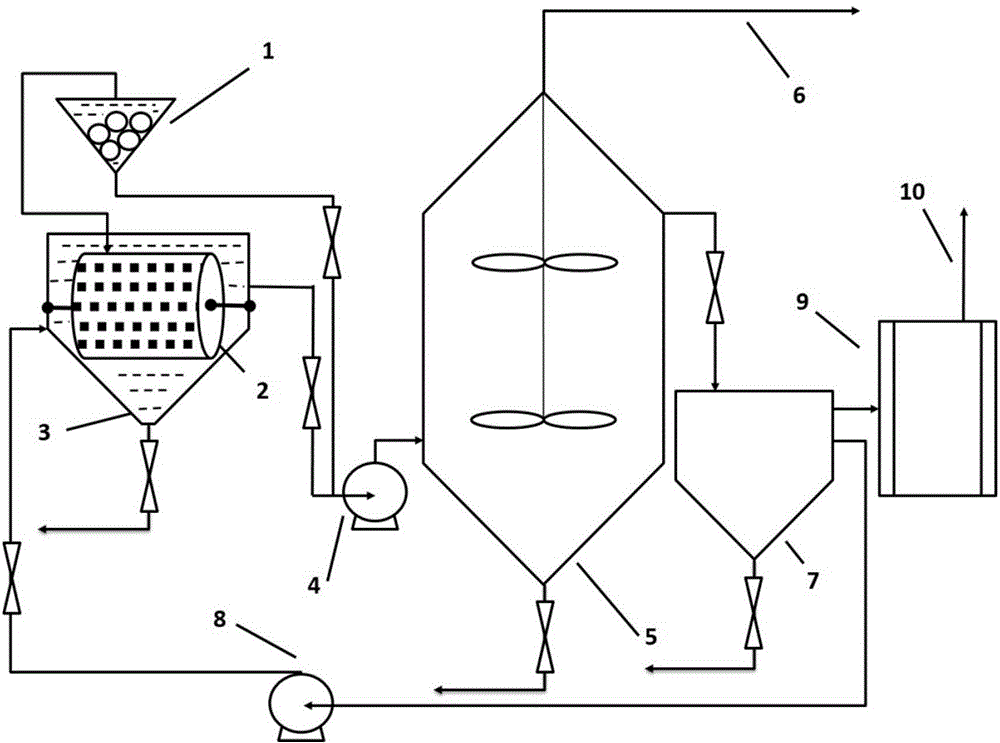

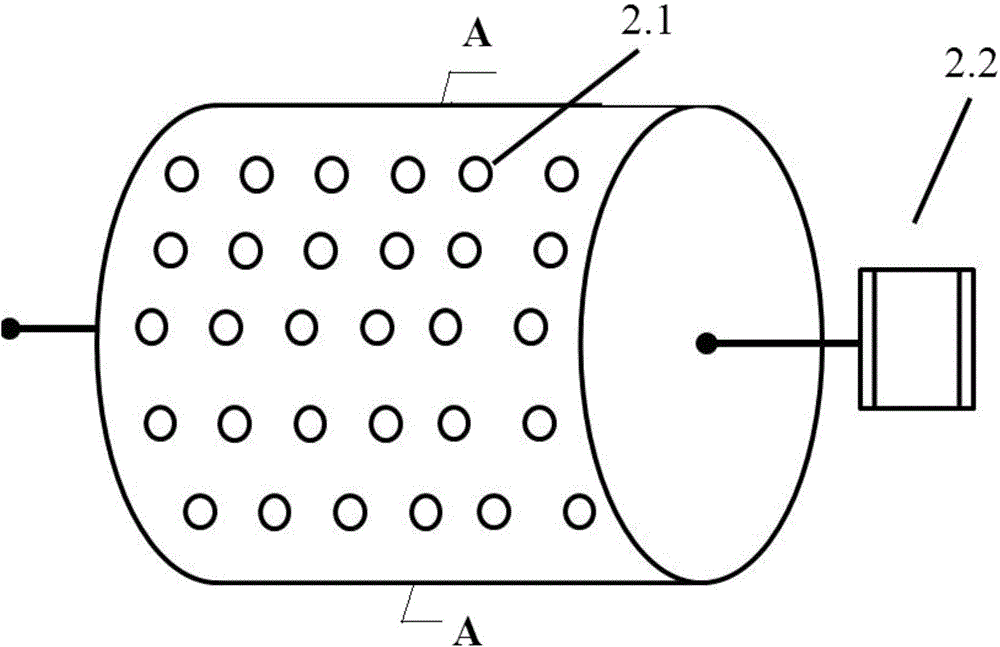

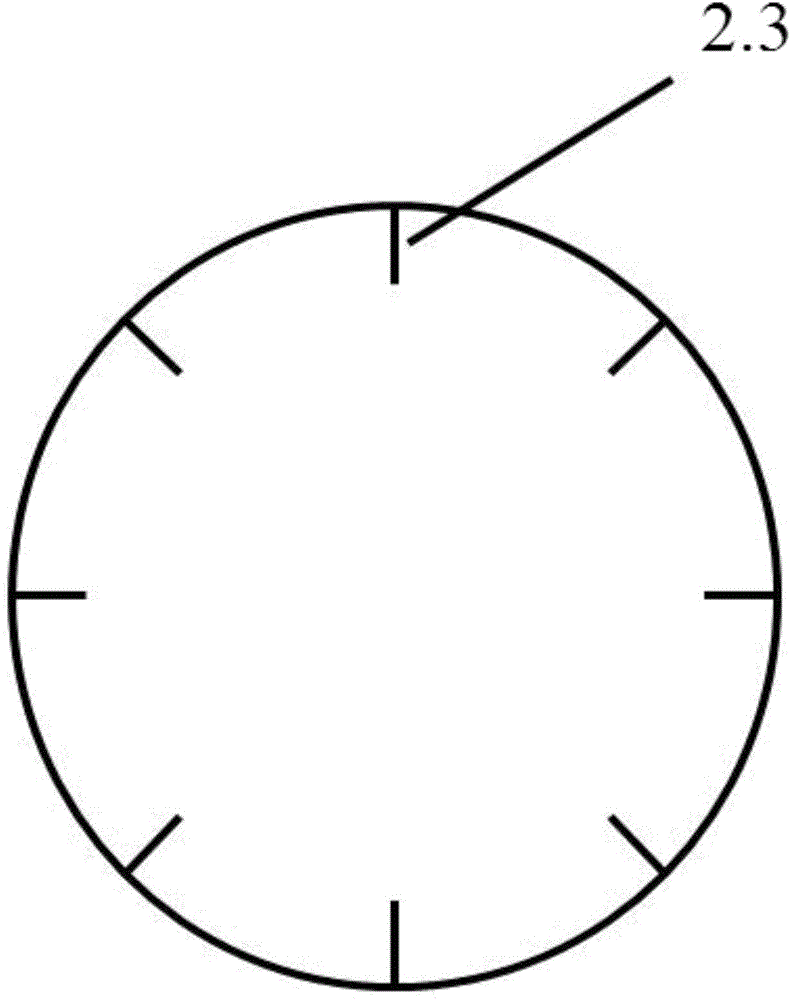

[0036] A device for producing biogas and liquid organic fertilizer from fruit and vegetable waste in a distribution center, such as figure 1 As shown, it includes a squeeze crusher 1, a rotatable hollow cylinder hydrolysis device 2 connected with the squeeze crusher 1, a hydrolysis grit chamber 3 equipped with an inoculation solution of hydrolyzed acid-producing bacteria, and a feed pump 4 , the anaerobic fermentation reactor 5 connected with the feed pump 4, the digestive juice sedimentation storage tank 7 connected with the anaerobic fermentation reactor 5, the high temperature sterilization device 9 connected with the digestive juice sedimentation storage tank 7, the refl...

Embodiment 2

[0046] Referring to Example 1, the difference is that the fruit and vegetable wastes are collected from the Guangzhou Changnan Farmer’s Market, containing impurities such as soft plastic bags, plastic lunch boxes, plastic bottles, paper beverage boxes, durian shells, coconut shells, onion skins, etc. Less digestible material.

[0047] The raw materials in this embodiment are subjected to anaerobic digestion of fruit and vegetable wastes, the methane production rate of the raw materials can reach 410L / kgVS, and the gas production rate of the tank capacity can reach 2.0L / L / d. The liquid fertilizer produced is rich in elements such as nitrogen, phosphorus, and potassium, among which Kjeldahl nitrogen, total phosphorus, and total potassium content are 1000mg / L, 67mg / L, and 2600mg / L respectively; mercury, cadmium, arsenic, hexavalent chromium, lead , copper and other heavy metals are lower than the water quality standards for farmland irrigation, suitable for use as fertilizers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com