Fermentation reactor integrating functions of stirring and crusting breaking and stirring crust-breaking method

A technology of agitator and reactor, which is applied in the field of fermentation reactor and shell breaking with stirring and breaking, which can solve the problems of low gas production performance and reduced gas production rate, and achieve increased gas production performance and gas production efficiency Improve and improve the effect of gas production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

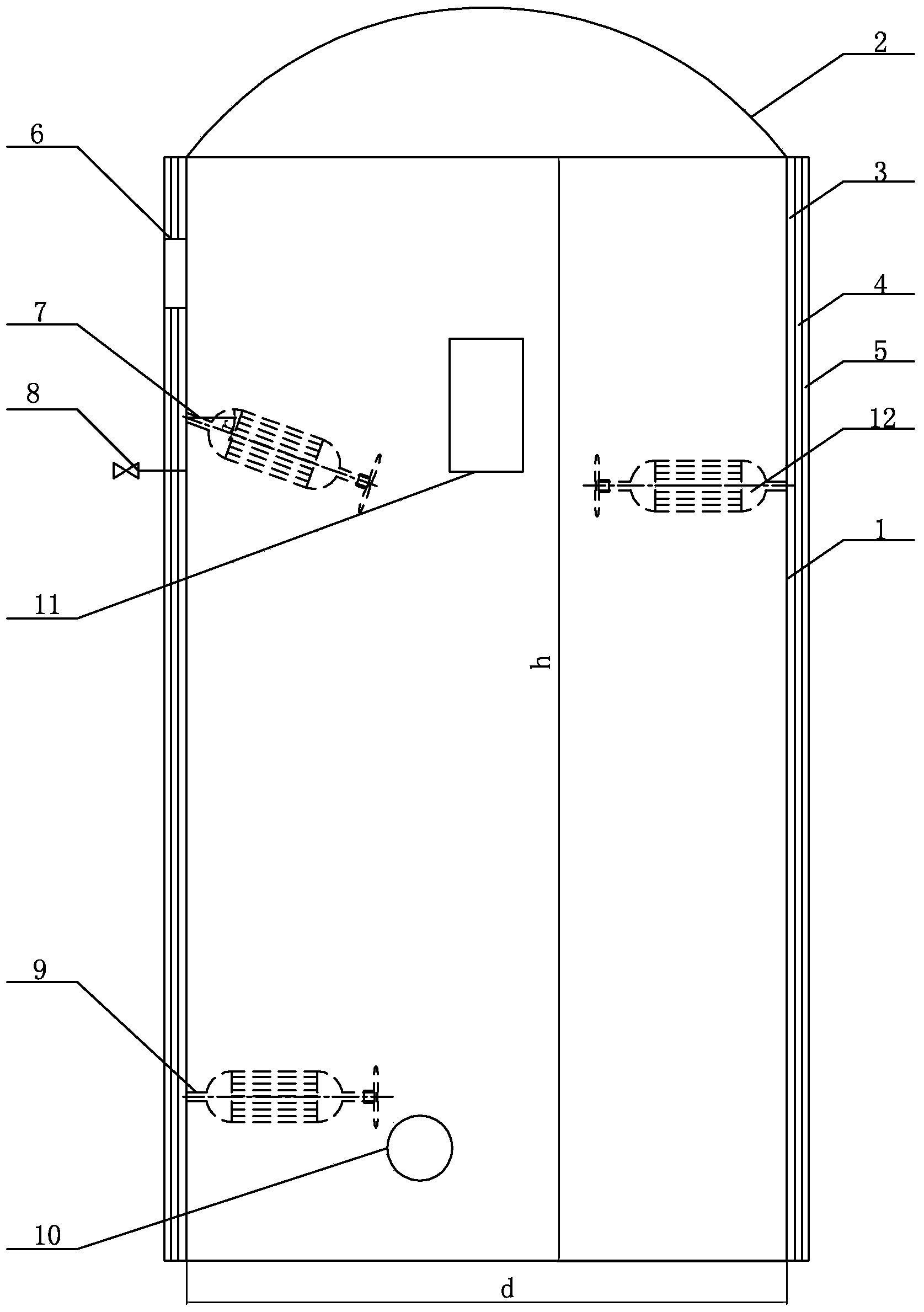

[0011] Specific implementation mode one: combine figure 1 Describe this embodiment, a fermentation reactor that integrates stirring and shell breaking, the fermentation reactor includes a digestion tank 1, a heating belt 3, an insulation layer 4 and a protective layer 5, and the fermentation reactor also includes a digestion tank upper cover 2. The first agitator 7 with a frequency converter, the material level gauge 8, the second agitator 9 with a frequency converter and the third agitator 12 with a frequency converter; the digestion tank 1 is barrel-shaped, and the digestion tank is The cover 2 is buckled on the digestion tank 1, the protective layer 5, the heat insulation layer 4 and the heating cable 3 are sequentially set on the outer wall of the digestion tank 1 from the outside to the inside, and the inner wall of the digestion tank 1 near the top is provided with an air outlet 6, and The air outlet 6 passes through the heating cable 3, the insulation layer 4 and the pr...

specific Embodiment approach 2

[0012] Specific implementation mode two: combination figure 1 Describe this embodiment, a kind of fermenting reactor that stirs and breaks shell in one, described fermenting reactor also comprises window 11, is provided with window 11 near the top of digestion tank 1, through window 11 observes the upper scum in digestion tank 1 and Crust situation, others are identical with specific embodiment one.

specific Embodiment approach 3

[0013] Specific implementation mode three: combination figure 1 This embodiment is described as a fermentation reactor in which stirring and shell breaking are integrated. The upper cover 2 of the digestion tank is made of rubber material. Others are the same as in the first embodiment.

[0014] Specific implementation mode four: combination figure 1 Description of this embodiment is a fermentation reactor that integrates stirring and breaking shells. The diameter of the digestion tank 1 is d, and the value of d is 5000-10000mm. The height of the digestion tank 1 is h, and the value of h is 10000-12000mm. Others are the same as in the first embodiment.

[0015] Specific implementation mode five: combination figure 1 Describe this embodiment, a fermentation reactor that integrates stirring and cracking the shell, the value of r is 10°-65°, and the speed of shell breaking can be increased by adjusting the angle of the first agitator 7, so that the gas production efficiency can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com