Displacement coalbed methane yield increase method under combined mining of coalbed methane by vertical wells and U-shaped butted well

A technology of joint mining and coalbed methane, which is applied in the fields of mining fluids, wellbore/well components, mining equipment, etc., can solve the problems of short high production time, difficult methane desorption, and low resource recovery in coalbed methane production wells. Improve gas production effect, save CBM surface development engineering and equipment investment, and improve recovery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the embodiment in the accompanying drawings:

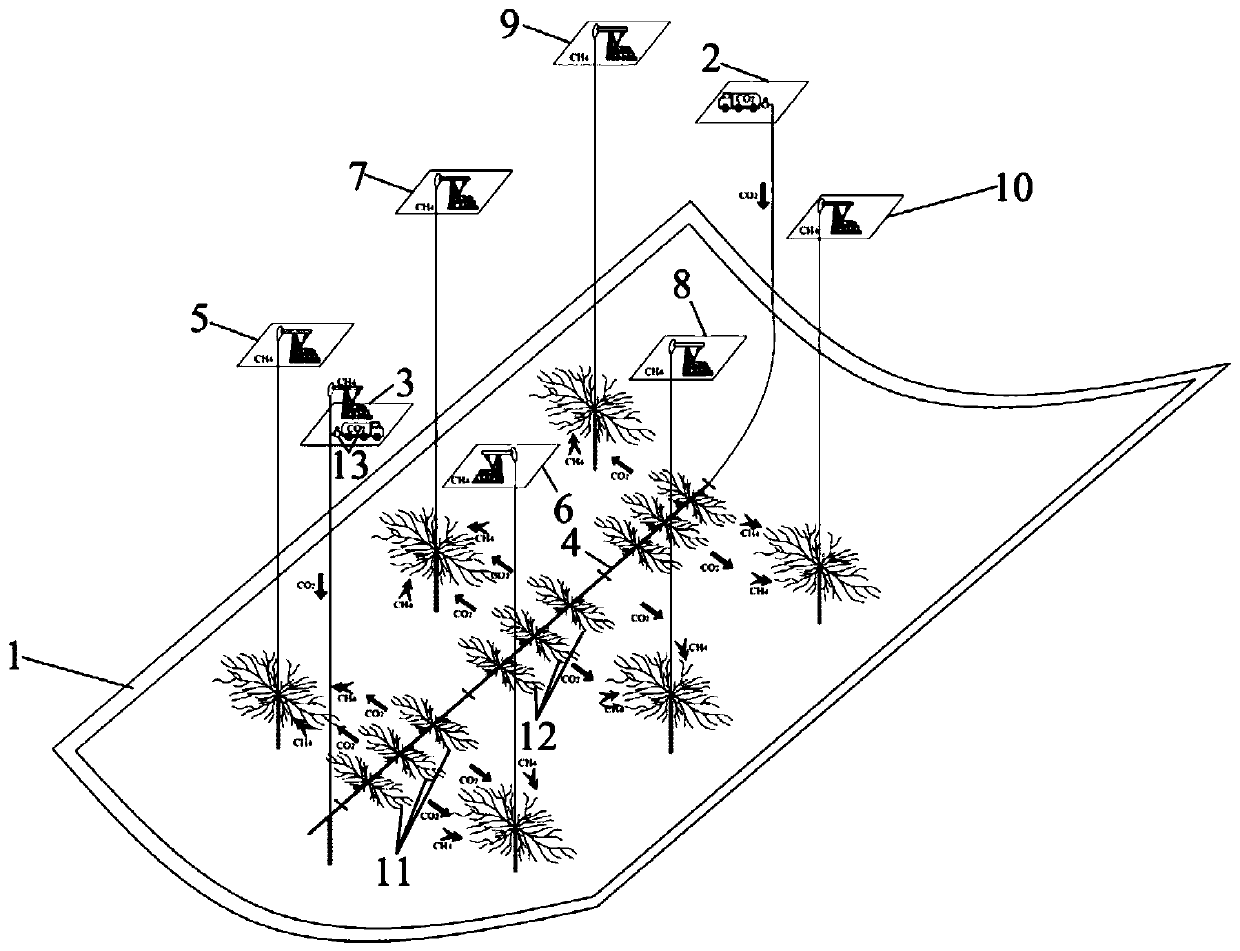

[0026] Such as figure 1 Shown, a kind of vertical well of the present invention and U-shaped butt joint well joint exploitation coalbed methane displacement coalbed methane production increasing method, concrete steps are as follows:

[0027] (a) At the burial depth of 600-800m in the target coal seam 1, construct a U-shaped distal butt joint well group along the line connecting the maximum bending point of the secondary syncline axis of the regional coal-bearing structure. The group includes a docked vertical well 3 and a directional horizontal well 2, the horizontal connecting section between the docked vertical well 3 and the directional horizontal well 2 is a horizontal well section 4, and production casing is run in the horizontal well section 4 and cemented; The directional horizontal well 2 adopts a three-cut well body structure. The first and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com