Venturi type multiphase fluid mixer and multiphase fluid mixing method

A multi-phase fluid, Venturi technology, applied in mixing methods, fluid mixers, chemical instruments and methods, etc., can solve the problem of poor mineralization effect of coal-water slurry, unstable negative pressure at the throat, and recovery rate of combustibles lower problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

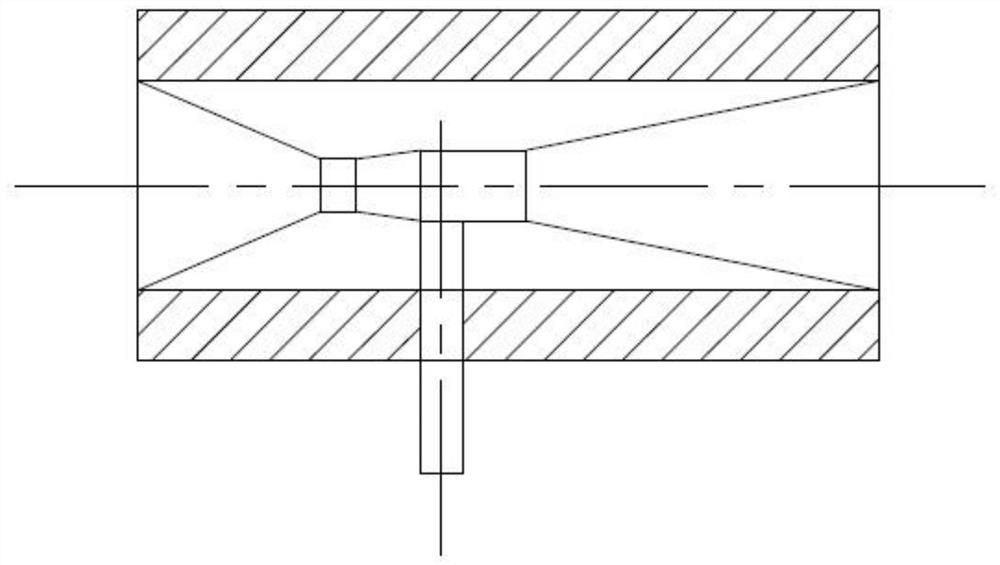

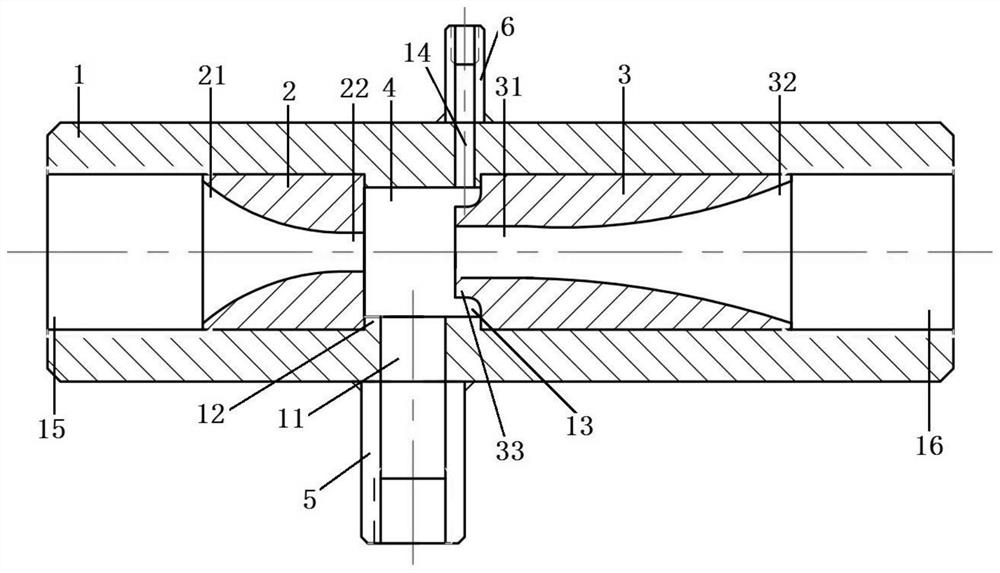

[0058] The Venturi type multiphase flow mixer that present embodiment adopts comprises following parts:

[0059] The sleeve 1 is open at both ends and has a cavity inside; its upstream end opening is a first material inlet 15, and its downstream end opening is a mixed material outlet 16; the first material enters the said first material inlet 15. Inside the sleeve 1;

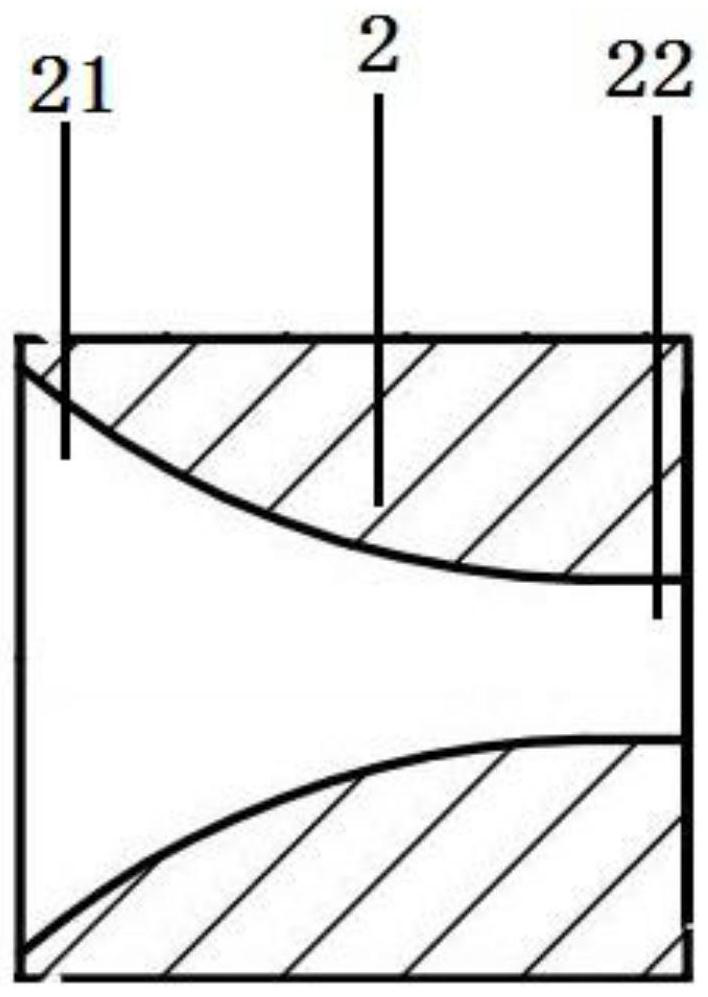

[0060] Upstream reducer 2, which is tapered from the upstream end to the downstream end, its upstream end is the first fluid inlet 21, the inlet diameter is 20mm, and its downstream end is the first fluid outlet 22, the outlet diameter is 6mm;

[0061] The downstream expanding pipe 3 is a pipe diameter gradually expanding type from the upstream end to the downstream end, and its upstream end is a second fluid inlet 31, and its downstream end is a second fluid outlet 32;

[0062] The multiphase fluid mixing chamber 4 is located in the cavity of the sleeve 1 and is defined between the upstream reducer 2 and the d...

Embodiment 2

[0070] The Venturi type multiphase flow mixer that present embodiment adopts comprises following parts:

[0071]The sleeve 1 is open at both ends and has a cavity inside; its upstream end opening is a first material inlet 15, and its downstream end opening is a mixed material outlet 16; the first material enters the said first material inlet 15. Inside the sleeve 1;

[0072] Upstream reducer 2, which is tapered from the upstream end to the downstream end, its upstream end is the first fluid inlet 21, its downstream end is the first fluid outlet 22, and the outlet diameter is 10mm;

[0073] The downstream expanding pipe 3 is a pipe diameter gradually expanding type from the upstream end to the downstream end, and its upstream end is a second fluid inlet 31, and its downstream end is a second fluid outlet 32;

[0074] The multiphase fluid mixing chamber 4 is located in the cavity of the sleeve 1 and is defined between the upstream reducer 2 and the downstream expander 3, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com