Method for replenishing hydrochloric acid for acid washing on rolled steel production line

A production line, hydrochloric acid technology, applied in the direction of metal rolling, metal rolling, workpiece surface treatment equipment, etc., can solve the problems of increasing the operating load of the pump, the container is easy to be deformed under pressure, etc., to prevent the volatilization of hydrochloric acid, facilitate the supply of pickling, Easy and simple effects to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

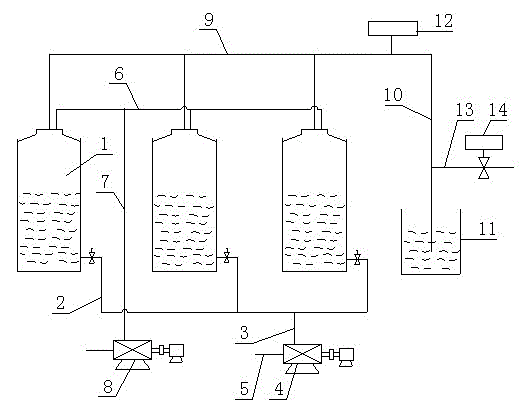

[0012] When this method is implemented specifically, the figure 1 device shown, as figure 1 As shown, a method for supplying hydrochloric acid for pickling in a steel rolling production line is characterized in that a plurality of hydrochloric acid containers 1 are arranged side by side, and the bottom of each hydrochloric acid container 1 is connected to each other by a first connecting pipe 2 and is supplied through a supply pipe 3. The pump 4 is connected to the production line pipeline 5 for pickling supply; the upper ends of the above-mentioned multiple hydrochloric acid containers 1 are connected to each other through the second communication pipeline 6 and then connected to the hydrochloric acid truck storage tank through the supply pipeline 7 through the new acid supply pump 8 to carry out hydrochloric acid replenishment; The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com