Hydraulic control system of friction welding machine

A technology of hydraulic control system and friction welding machine, which is applied in the field of machinery, can solve problems such as heat discharge, rising oil temperature, and large useless power, and achieve the effects of reducing power consumption, stabilizing oil temperature, and reducing power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

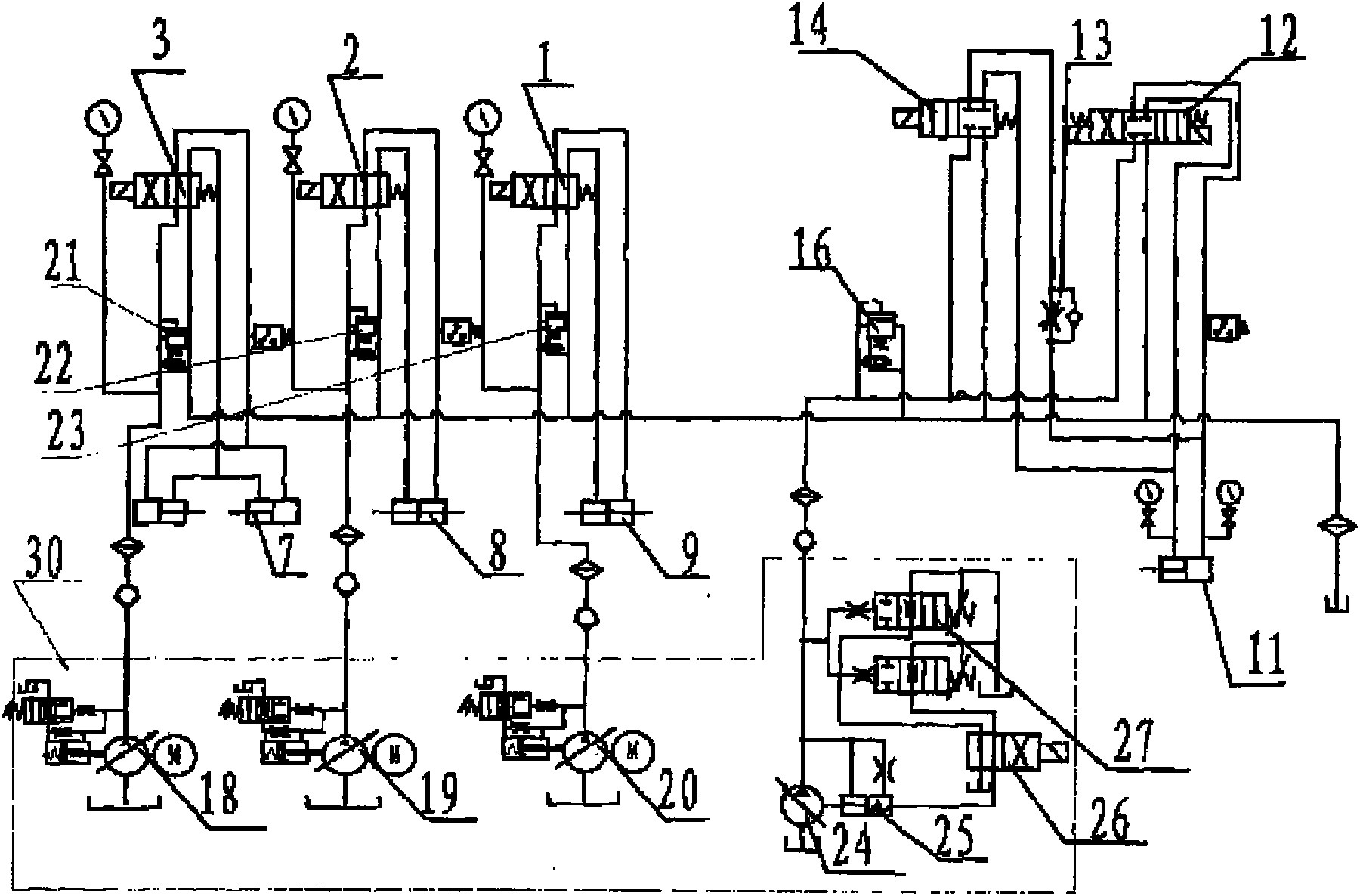

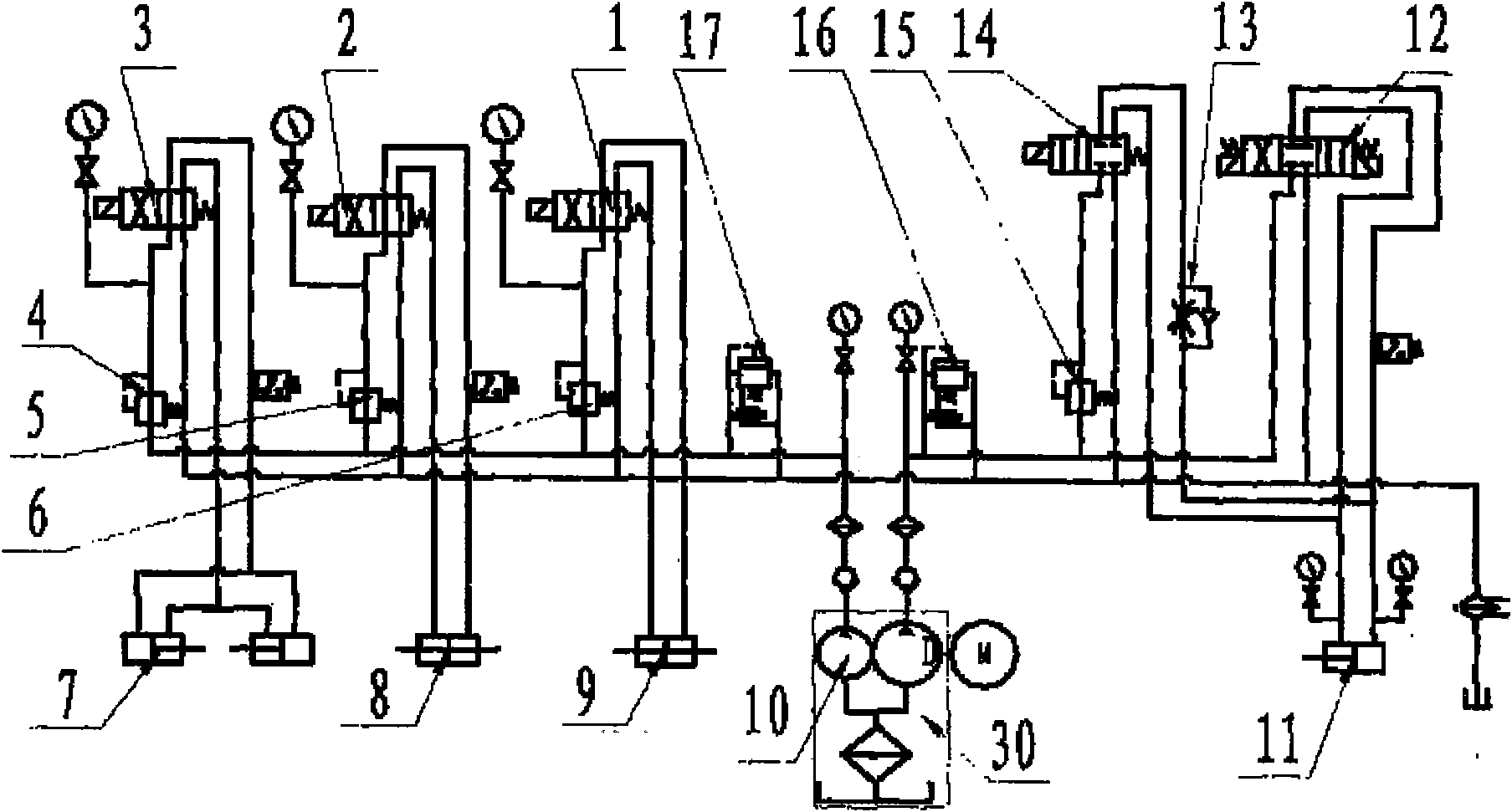

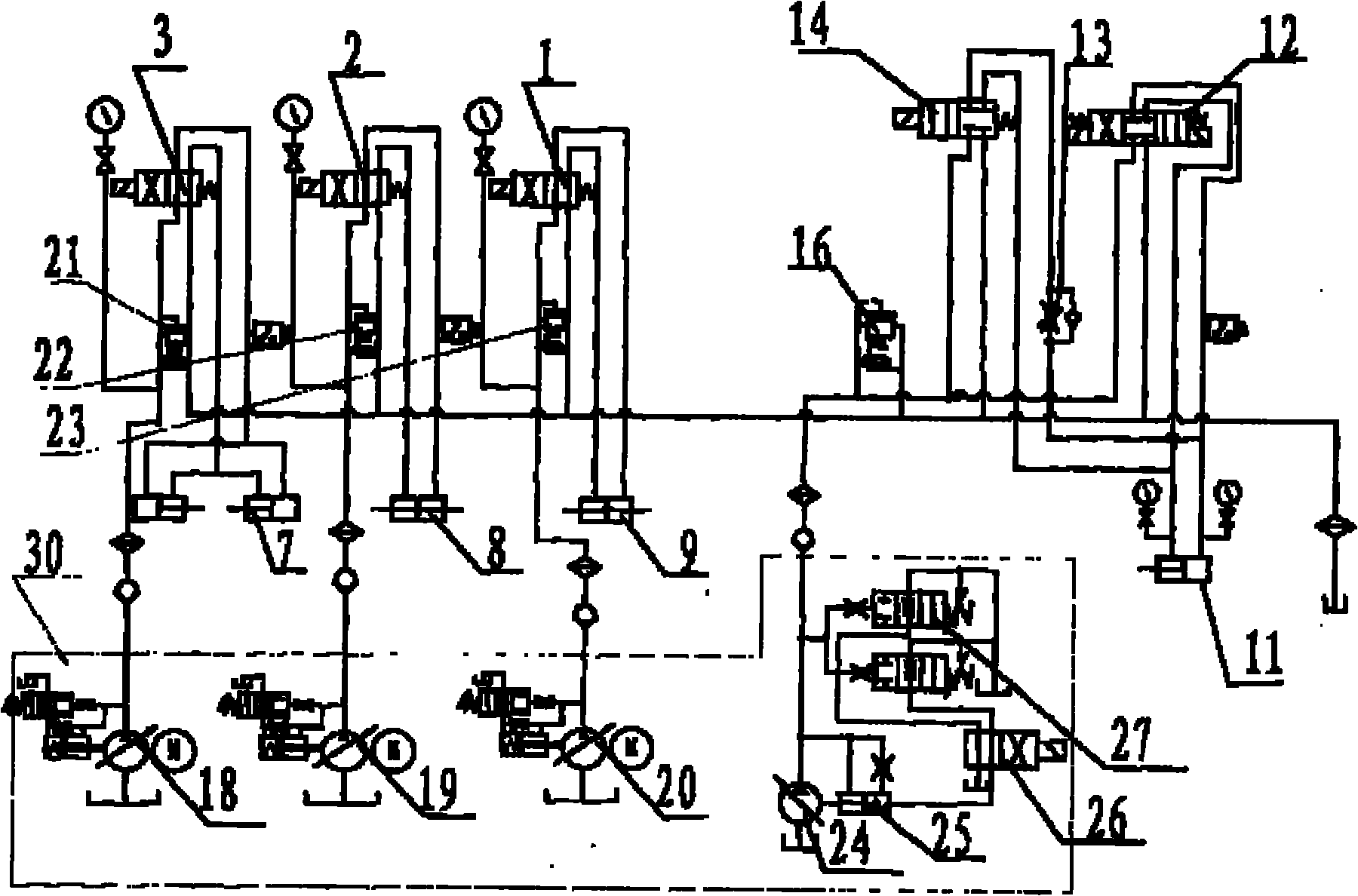

[0010] refer to figure 1 , the present invention includes a two-position four-way reversing valve, a pressure reducing valve, an oil cylinder, a three-position four-way reversing valve, a speed regulating valve, an electromagnetic overflow valve and a pump source device, and its pump source device 30 consists of a constant pressure variable pump A18 , constant pressure variable pump B19, constant pressure variable displacement pump C20, and two-stage constant pressure variable pump 24 serve as pressure reducing valves D15 for controlling friction and working pressure in the prior art, reducing the control of moving fixture oil cylinder 7 and rotating fixture Pressure reducing valve A4, pressure reducing valve B5 and pressure reducing valve C6 of pressure required for oil cylinder 8 and clutch brake oil cylinder 9 actions have also reduced the electromagnetic overflow valve B 17 that controls the pressure of the small pump of double quantitative pump 10. Electromagnetic overfl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com