Method and device for controlling pressure in fire-resistance rating test furnace

A technology of refractory limit and control device, which is applied to furnace control device, furnace, furnace type, etc., can solve the problems of control, no test furnace pressure is proposed, and achieve the effect of uniform pressure distribution control and reducing direct influence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

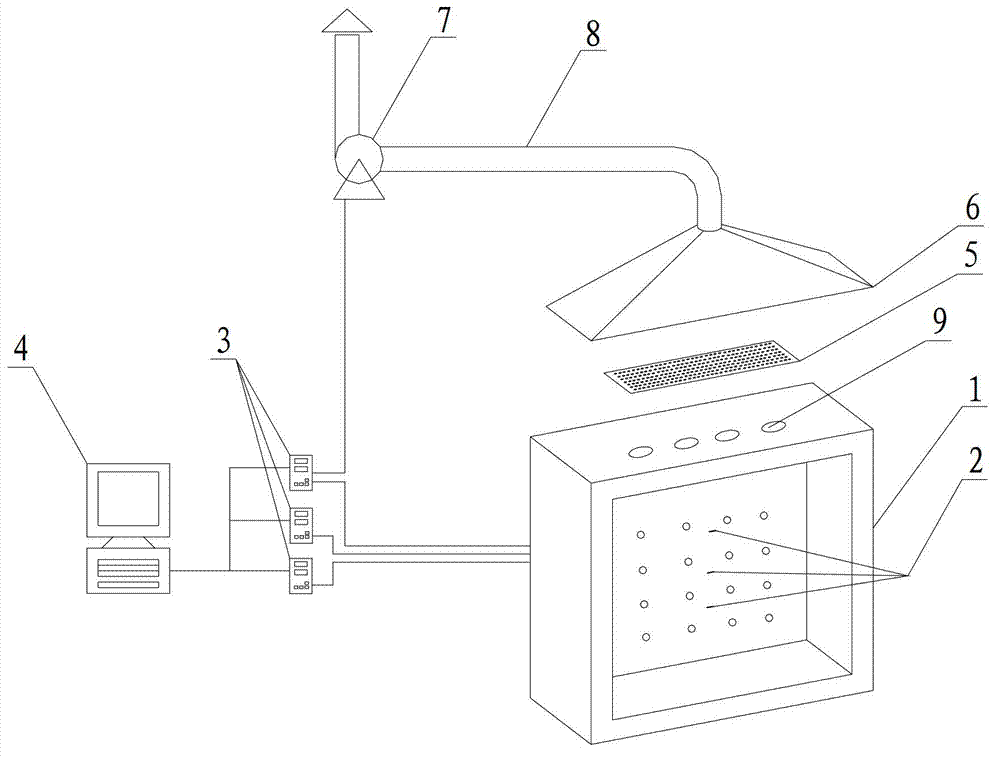

[0029] Such as figure 1 As shown, in this embodiment, a pressure control device in a fire resistance limit test furnace includes a fire resistance limit test furnace 1 for exhausting smoke at the top, a pressure sensor 2 in the furnace, a PID controller 3, a computer 4, a smoke collecting hood 6, and a smoke exhaust fan 7. The smoke exhaust pipe 8 and the porous smoke exhaust steady flow net 5, the pressure sensor 2 in the furnace is set in the fire resistance limit test furnace 1, connected with the PID controller 3, and used to transmit the actual pressure data in the furnace to the PID controller 3 . The computer 4 is connected with the PID controller 3 for transmitting the target pressure data to the PID controller 3 . The PID controller 3 is used to compare and analyze the actual furnace pressure data and the target pressure data, and then control the speed of the exhaust fan 7 according to the analysis results. The porous smoke exhaust stabilizing net 5 is covered on t...

Embodiment 2

[0040] Present embodiment except following feature other structures are with embodiment 1:

[0041] In this embodiment, the number of pressure sensor 2 in the furnace is one, and the output type of the pressure sensor is 0~5V. The number of the PID controller 3 is one, and the PID controller 3 is connected with the computer 4 , the pressure sensor 2 and the exhaust fan 7 respectively.

[0042] The smoke exhaust hole 9 on the top of the test furnace is located at the top of the test furnace 1, the number of smoke exhaust holes 9 is 2, and the cross-sectional area of a single smoke exhaust hole is 0.5m 2 .

[0043] The porous smoke exhaust and flow stabilization net 5 is a porous plate made of high temperature resistant ceramics, the thickness of the plate is 15mm, the through-hole ratio of the plate is 30%, and the diameter of the hole is 20mm. The perforated plate is directly covered on the smoke exhaust hole 9, and the quantity of the porous plate can be 2, each covering ...

Embodiment 3

[0046] Present embodiment except following feature other structures are with embodiment 1:

[0047] In this embodiment, the number of pressure sensors 2 in the furnace is five, and the output type of the pressure sensors is 4-20 mA. The number of PID controllers 3 is five, and each PID controller 3 is connected with the computer 4 and the pressure sensor 2 respectively, and one of them is also connected with the exhaust fan 7 .

[0048] In the present embodiment, the number of smoke exhaust holes 9 is 10, and the cross-sectional area of a single smoke exhaust hole is 0.1m 2 . The porous smoke exhaust stabilization net 5 is a porous plate made of high temperature resistant ceramics, the thickness of the plate is 100mm, the through-porosity of the plate is 50%, and the diameter of the hole is 10mm. The number of perforated plates is 10, and one smoke exhaust hole is covered at the same time.

[0049] The height of the gap between the bottom four sides of the fume collecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com