Inner peripheral heating corrugated roller

A corrugated roll and inner peripheral technology, applied in the field of corrugated rolls, can solve the problems of increased heat loss, large heating cylinder space, and deformation of the roll body, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

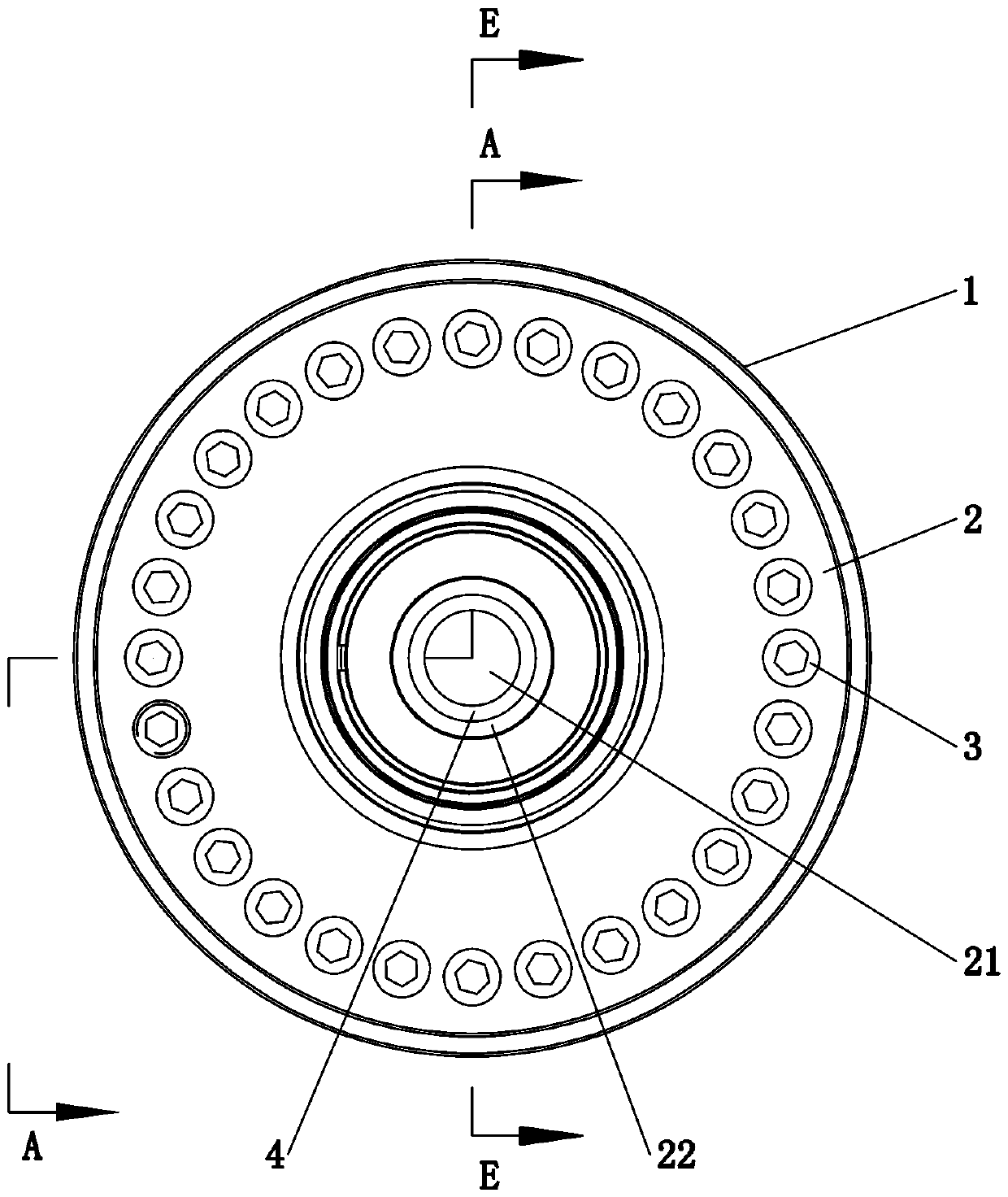

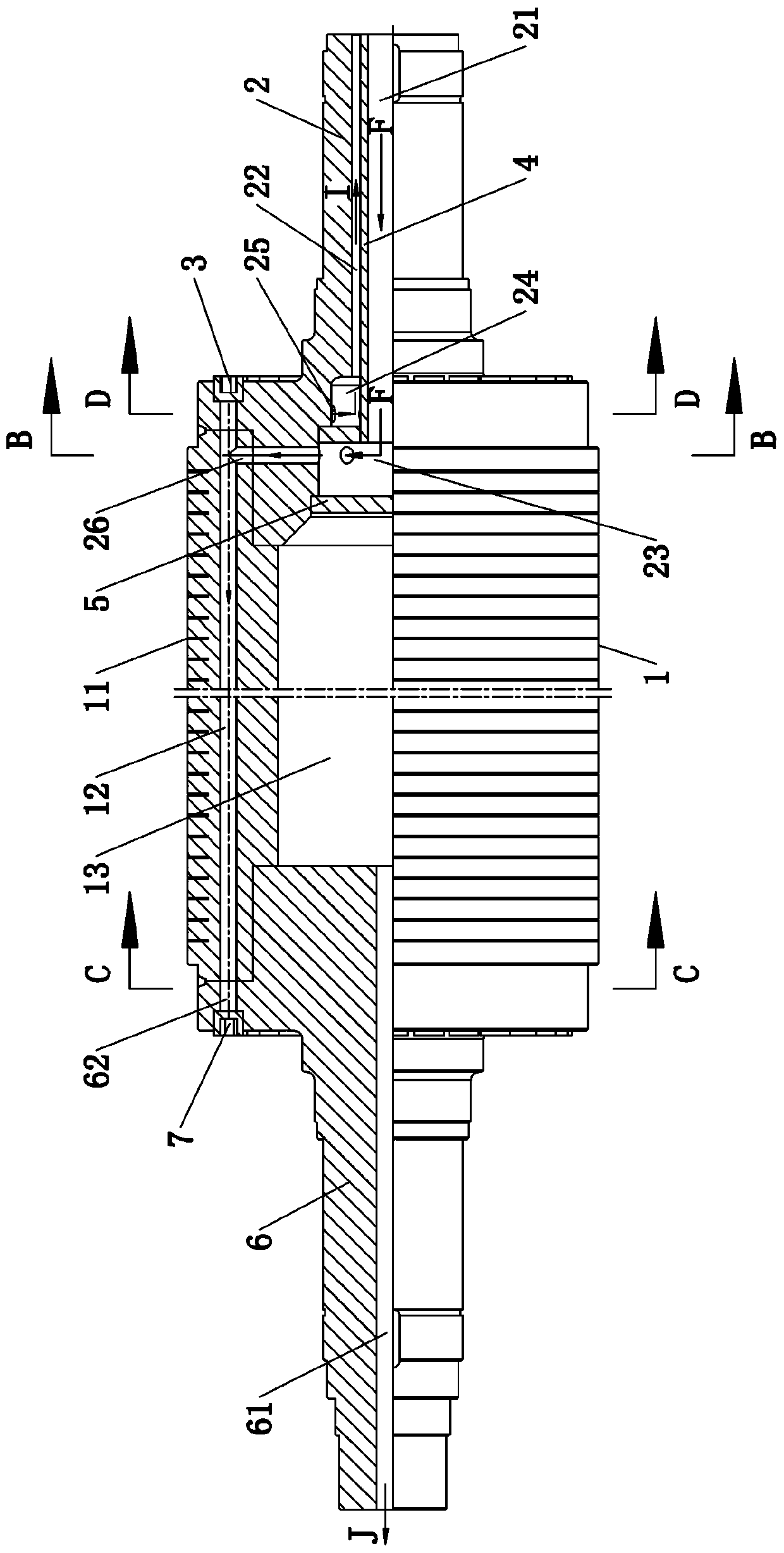

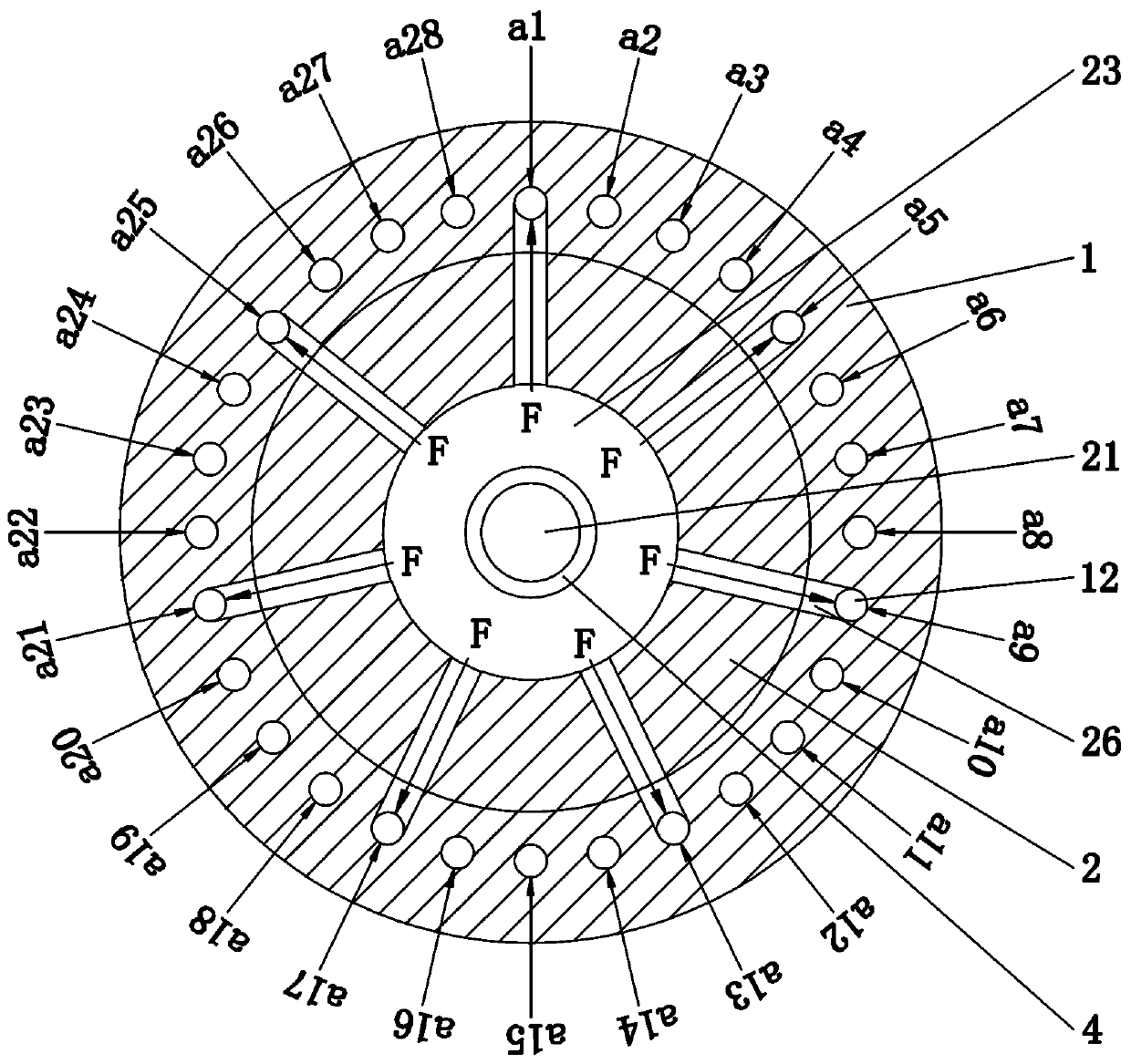

[0028] see Figure 1 to Figure 6 As shown, a corrugating roller heated at the inner periphery includes a corrugating roller body, and multiple groups of steam passages are arranged in the corrugating roller body, and each group of steam passages is uniformly distributed around the center of the corrugating roller body and is close to the outer surface of the corrugating roller body. On the wall, each group of steam channels includes four pipelines 12, the pipelines 12 are directed along the axis of the corrugating roller body, and each pipeline 12 is connected in sequence; one end of the corrugating roller body is provided with a steam inlet channel 21 and a steam return channel 22, each group Both ends of the steam channel communicate with the steam inlet channel 21 and the steam return channel 22 respectively.

[0029] The corrugating roll body includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com