Friction welding machine constant voltage variable hydraulic control system

A technology of hydraulic control system and friction welding machine, which is applied in the direction of mechanical equipment, manufacturing tools, welding equipment, etc. It can solve the problems of heat discharge, high useless power, and rising oil temperature, so as to stabilize oil temperature, reduce power loss, Effect of Power Consumption Reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

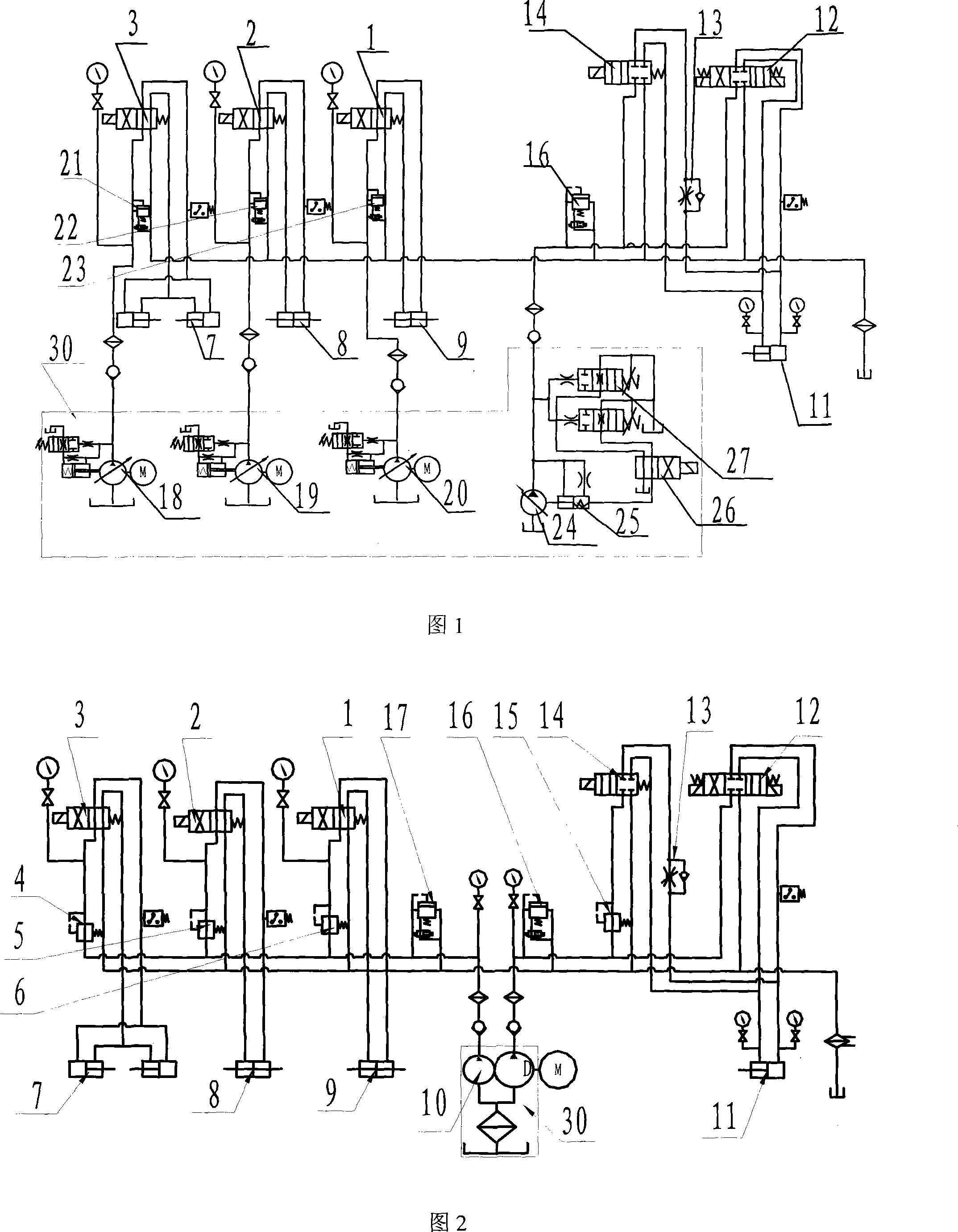

[0012] With reference to Fig. 1, the present invention comprises two-position four-way reversing valve, decompression valve, oil cylinder, three-position four-way reversing valve, speed regulating valve, electromagnetic overflow valve and pump source device, and its pump source device 30 is made of constant pressure The variable pump A18, the constant pressure variable pump B19, the constant pressure variable pump C20 and the two-stage constant pressure variable pump 24 are used to reduce the pressure reducing valve D15 used to control friction and working pressure in the prior art, and reduce the control of the movable fixture oil cylinder 7, The pressure relief valve A4, pressure relief valve B5 and pressure relief valve C6 required for the action of the rotating fixture cylinder 8 and the clutch brake cylinder 9 also reduce the electromagnetic overflow valve B17 that controls the pressure of the small pump of the double quantitative pump 10. Electromagnetic overflow valve C2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com