Hot rolled seamless steel pipe on-line cooling system and arrangement method of cooling device on hot rolled seamless steel pipe on-line cooling system

A technology for cooling devices and seamless steel pipes, which is applied in the direction of workpiece cooling devices, metal rolling, metal rolling, etc., can solve the problems of excessive growth of austenite grains, low comprehensive performance of steel pipes, and affecting the mechanical properties of steel pipes, etc. Achieve the effects of grain refinement, improvement of comprehensive performance, and reduction of waiting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

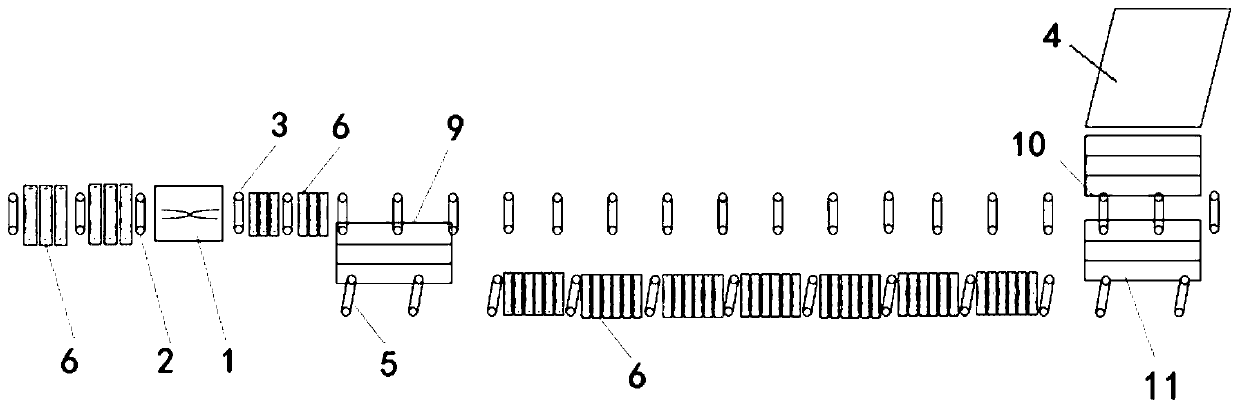

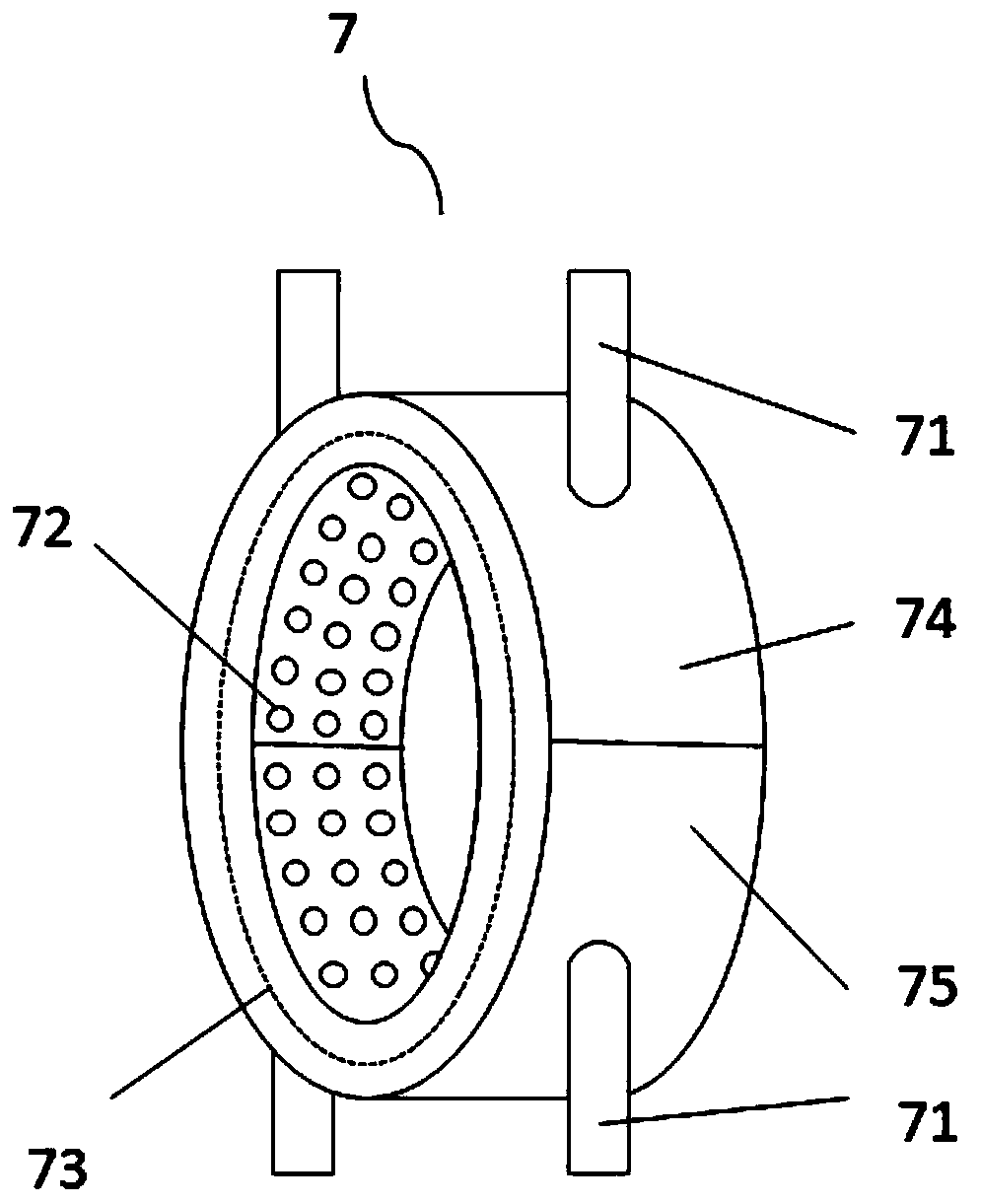

[0053] According to the product process requirements of the production line, the cooling device 6 is arranged on the roller table 2 before sizing, and the height of the cooling device 6 can be adjusted with the height of the roller table 2 before sizing, so as to realize the central cooling of the steel pipe, which is 8 sets of circular water spray rings , the cooling water spray ring 7 is composed of an upper water spray ring and a lower water spray ring with an inner diameter of 650mm symmetrically arranged up and down; 6 rows of cooling nozzles are evenly arranged on the inner surface of the water spray ring, and the number of cooling nozzles in a single row is 52. The water pressure adjustment range of the water ring is 0.2-0.8MPa, the flow rate of the upper and lower spray rings can be independently controlled, the spray flow range is 80-150m3 / h, and the water ratio of the upper and lower spray rings is within the range of 1.05-1.5. The water inlet 71 is arranged on the ou...

Embodiment 2

[0056] According to the product process requirements of the production line, the cooling device 6 is arranged at the roller table 3 after sizing and the cooling roller table 5 between the sizing machine 1 and the cooling bed 4 .

[0057] The cooling device 6 installed on the roller table 3 after sizing is 10 integral water spray rings 8. The inner diameter of the water spray ring is 660mm, and the inner surface of the water spray ring is evenly arranged in the width direction with multiple rows of cooling nozzles. In order to realize water spray cooling on the outer surface of the steel pipe, the number of cooling nozzles in a single row is 36-70, and the outer surface of the water spray ring is arranged with a water inlet 81, which is connected to the diversion water collection pipe through the water supply pipeline and the regulating valve group. For the realization of spray ring flow control. The water pressure adjustment range of the water spray ring is 0.2-0.8MPa, the flo...

Embodiment 3

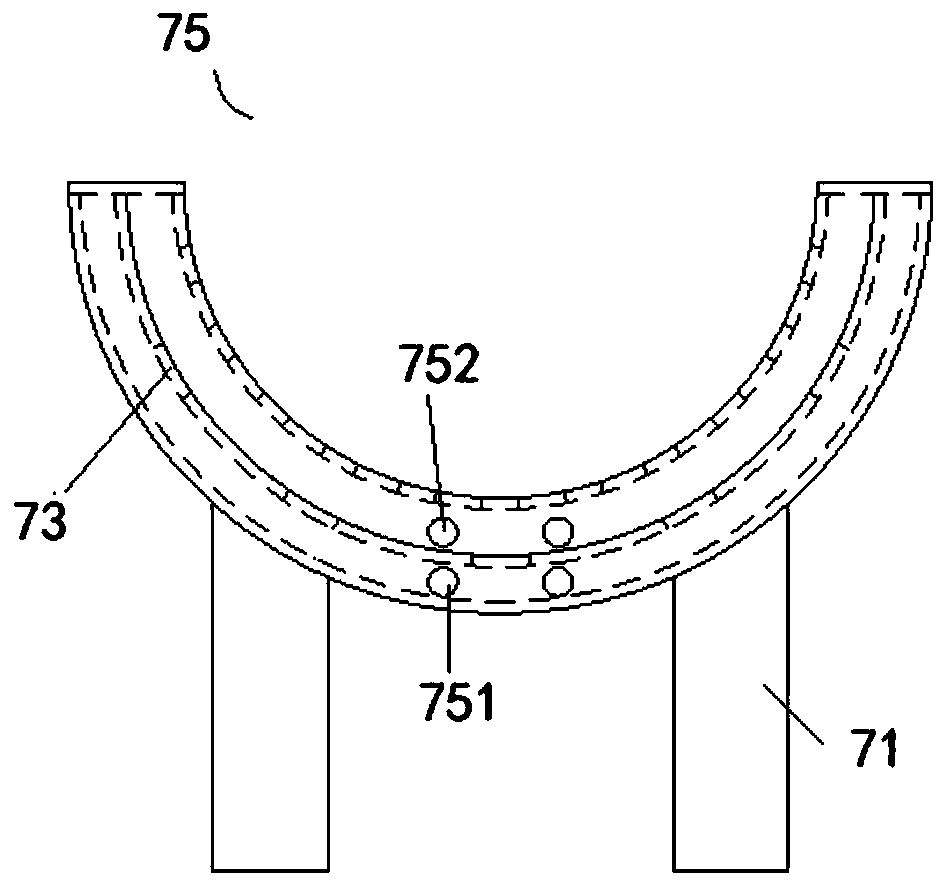

[0062] According to the product process requirements of the production line, the cooling device 6 is arranged at 2 roller tables before sizing, 3 roller tables after sizing, and 5 cooling roller tables between the sizing machine 1 and the cooling bed 4. The cooling water spray ring 7 is composed of an upper half water spray ring 74 and a lower half water spray ring 75 arranged symmetrically up and down. The inner surface of the water spray ring is evenly arranged in the width direction with multiple rows of cooling nozzles, which are used to spray water on the outer surface of the steel pipe for cooling. , the number of single-row cooling nozzles is 36 to 70, and the outer surface of the water spray ring is arranged with a water inlet 71, which is connected to the diversion water collection pipe through the water supply pipeline and the regulating valve group. The water collecting pipe is provided with a number of bypass pipes. By adjusting the opening degree of the bypass pipe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com