A method for evaluating ultra-high molecular weight polyethylene resin with online rheometer

A technology of ultra-high molecular weight and polyethylene resin, applied in the direction of DC flow characteristics measurement, etc., can solve problems such as unsatisfactory, incompletely consistent states, and inability to truly reflect the rheological properties of polymer melts, and achieve accurate and effective results. Good and efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

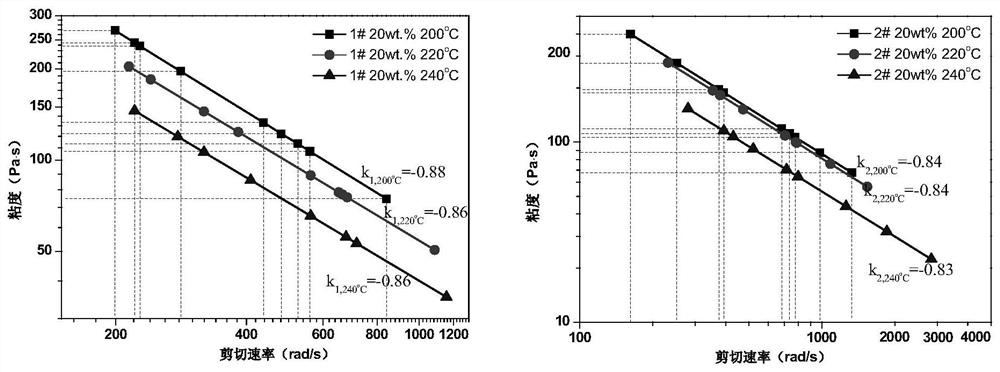

[0042] Get two kinds of ultra-high-molecular-weight polyethylene resins with different performance characteristics, numbering 1#, 2#, dissolve them in paraffin oil respectively, add antioxidant 168, and the mass concentration is 0.1wt.%, to form a semi-dilute solution (ultra-high molecular weight The concentration of polyethylene is 20wt.%). After feeding the obtained semi-dilute solution into the twin-screw extruder, open the pressure closed-loop control system to provide a stable extrusion pressure, and open the side channel between the extruder melt pump and die The melt enters the capillary rheometer at a constant pressure, and is extruded through the die of the capillary rheometer, and the obtained online rheological parameters (test results such as figure 1 As shown, the k value represents the slope of the straight line) to regulate its processing technology, then cast or calender to form a nascent film, and finally judge the film-forming performance by thermally induced ...

Embodiment 2

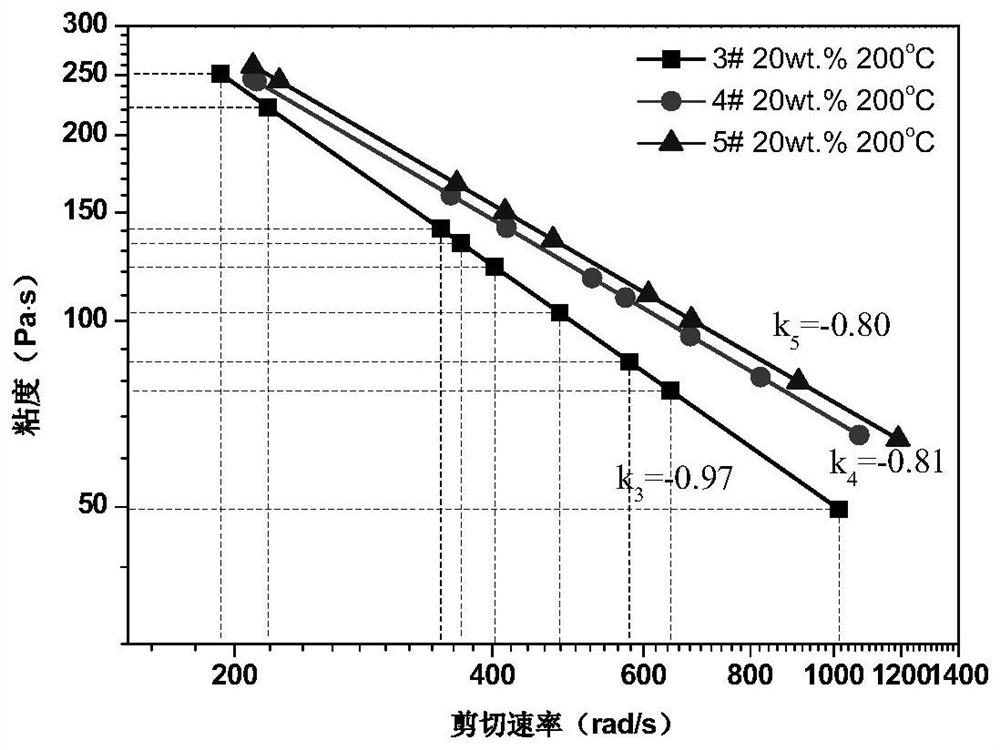

[0048] Get ultra-high molecular weight polyethylene resins with different performance characteristics, numbering 3#, 4#, 5#, dissolve them in paraffin oil respectively, add antioxidant 1076, and the concentration is 0.1wt.%, to form a semi-dilute solution (ultrahigh Molecular weight polyethylene concentration is 20wt.%), after feeding the obtained semi-dilute solution into the twin-screw extruder, open the pressure closed-loop control system to provide a stable extrusion pressure, and open the side path between the extruder melt pump and the mouth The valve between the molds, the melt enters the capillary rheometer at a constant pressure, and is extruded through the die of the capillary rheometer, and the obtained online rheological parameters (test results such as figure 2 As shown, the k value represents the slope of the straight line) to regulate its processing technology, then cast or calender to form a nascent film, and finally judge the film-forming performance by therma...

Embodiment 3

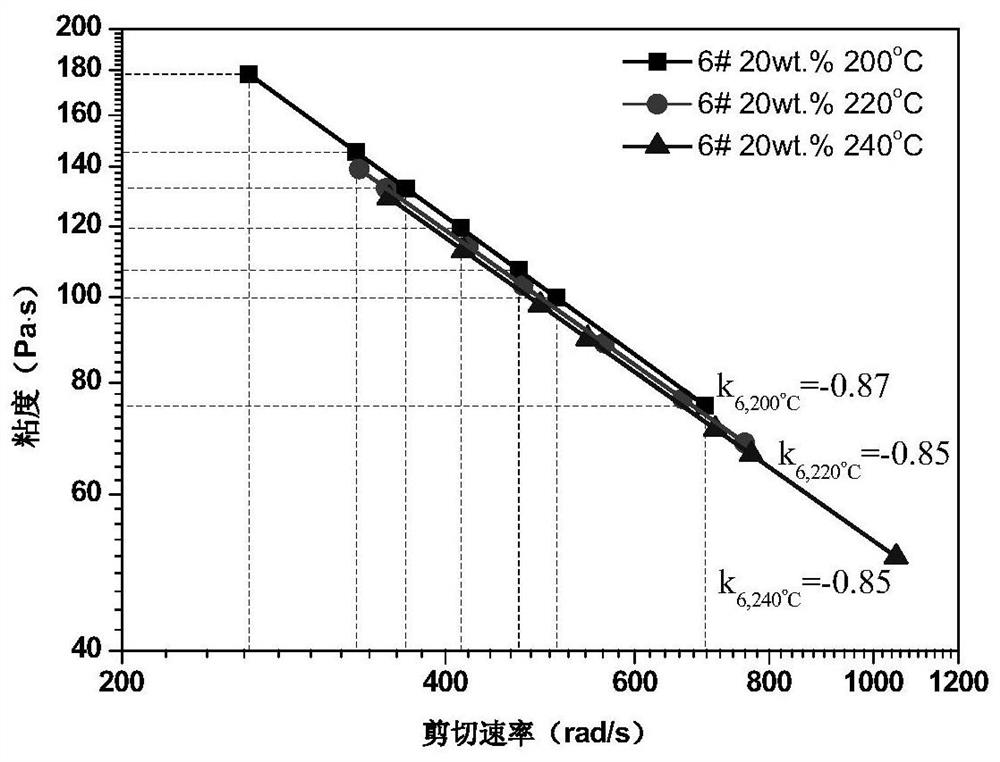

[0053] Get ultra-high molecular weight polyethylene resin, number 6#, dissolve in paraffin oil respectively, add antioxidant 1076, concentration is 0.1wt.%, form semi-dilute solution (concentration of ultra-high molecular weight polyethylene is 20wt.%), After feeding the obtained semi-dilute solution into the twin-screw extruder at different processing temperatures, open the pressure closed-loop control system to provide stable extrusion pressure, open the side channel between the extruder melt pump and the die valve, the melt enters the capillary rheometer at a constant pressure, is extruded through the die of the capillary rheometer, and passes through the online rheological parameters obtained (test results such as image 3 As shown, the k value represents the slope of the straight line) to regulate its processing technology, then cast or calender to form a nascent film, and finally judge the film-forming performance by thermally induced phase separation and biaxial stretchi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com