A control device for melt flow heat field for producing wide-width cast-rolled plates

A technology of regulating device and flow regulating device, which is applied in the field of metallurgical equipment, can solve the problems of not being able to meet the requirements of the thermal field of the wide-width production flow, unable to ensure the melt at the entrance of the wide-width casting nozzle, and difficult to realize the production of wide-width cast-rolled plates, etc. , to achieve good heat insulation effect, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

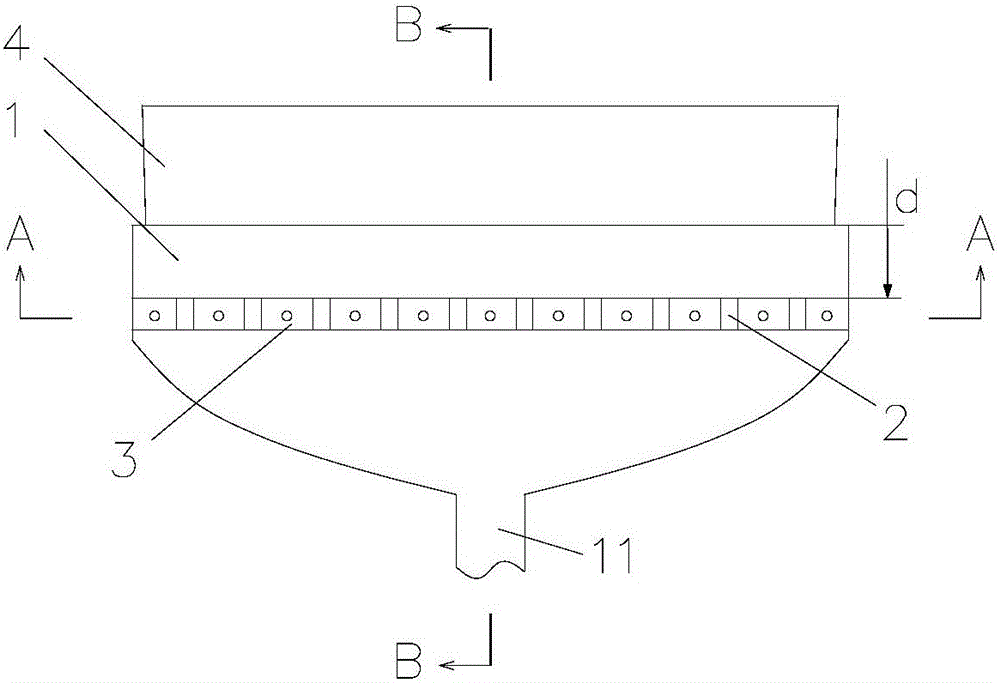

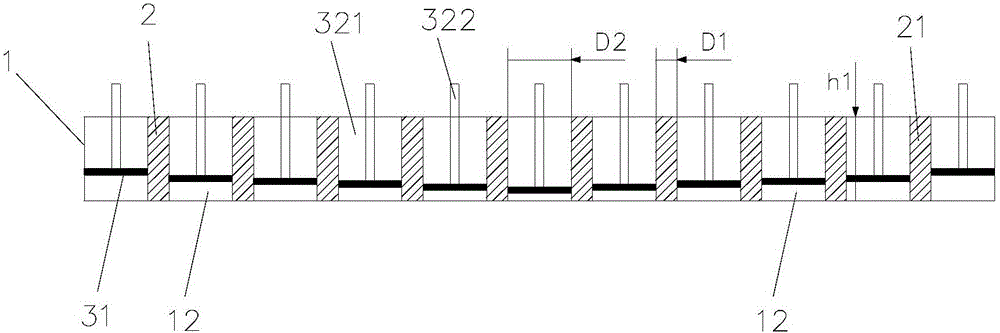

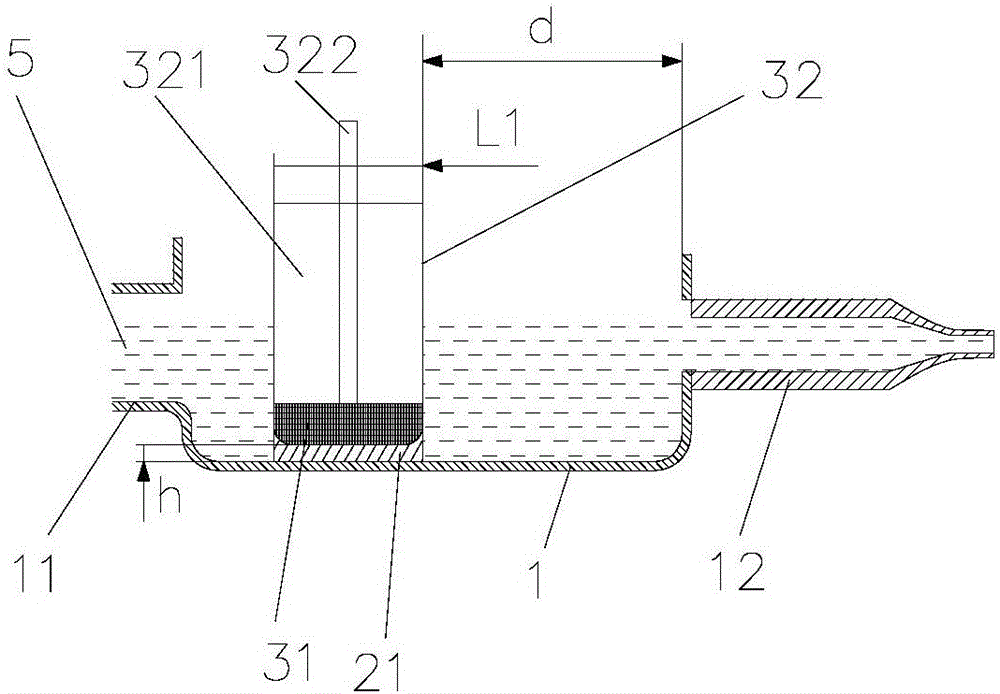

[0031] This embodiment provides a control device for producing a melt flow heat field for wide-width cast-rolled plates, such as figure 1 as well as figure 2 , when the melt 5 flows through the channel 12, such as image 3 As shown, the overall structure is simplified and the production cost is low.

[0032] The device includes a thermal insulation component 2 and a control device 3, the thermal insulation component 2 includes N thermal insulation monomers 21, N is greater than or equal to 2, preferably 6-14, which can meet the actual production requirements of more than 2000mm Demand for wide-width cast-rolled plates.

[0033] The regulating device 3 includes a temperature regulating device 31 and a flow regulating device 32 , and the temperature regulating device 31 is arranged on the flow regulating device 32 .

[0034] The heat insulation component 2 is arranged in the front box body 1, and the front box body 1 is divided into M cavities by the heat insulation unit 21,...

Embodiment 2

[0043] The production width of the 1060 aluminum alloy cast-rolled slabs with a width of 1950mm is as follows:

[0044] The heat insulation unit 21 divides the front box body 1 into 9 cavities, the number of heat insulation units 21 is 8, the width D2 of the cavity is 200 mm, and the width D1 of the heat insulation unit 21 is Both are 60 mm, the length L1 is 100 mm, and the distance d from the front end of the thermal insulation unit 21 to the nozzle 4 is 200 mm.

[0045] The distance h from the bottom of the control device 3 to the bottom of the front box 1 is set to 15 mm, 17 mm, 21 mm and 25 mm from the middle to both sides.

[0046]During the production process, according to the online measurement of the temperature of each section at the entrance of the nozzle 12, the adjustment is made according to the difference between the measured temperature of each section and the expected period. When the measured value is 3°C higher or lower than the expected value, the correspond...

Embodiment 3

[0049] The production width of the 1235 aluminum alloy cast-rolled slabs of 2080mm by the regulation and control device of the melt flow thermal field used in the production of wide-width cast-rolled slabs of Example 1 is as follows:

[0050] The heat insulation unit 21 divides the front box body 1 into 11 cavities, the number of heat insulation units 21 is 10, the width D2 of the cavity is 150 mm, and the width D1 of the heat insulation unit 21 is Both are 50 mm, the length L1 is 100 mm, and the distance d from the front end of the thermal insulation unit 21 to the nozzle 4 is 230 mm.

[0051] The distance h from the bottom of the control device 3 to the bottom of the front box 1 is set to 15 mm, 16 mm, 19 mm, 23 mm and 30 mm from the middle to both sides.

[0052] During the production process, according to the online measurement of the temperature of each section at the entrance of the nozzle 12, the adjustment is made according to the difference between the measured temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com