Group control method of spraying flow in pwm intermittent spraying variable spraying system

A spray-type, flow-rate technology, which is applied to spray devices, electric controllers, controllers with specific characteristics, etc., can solve the problems of no control method, and the inability to realize closed-loop control of the spraying flow of the nozzle, so as to achieve cost savings, The effect of high control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

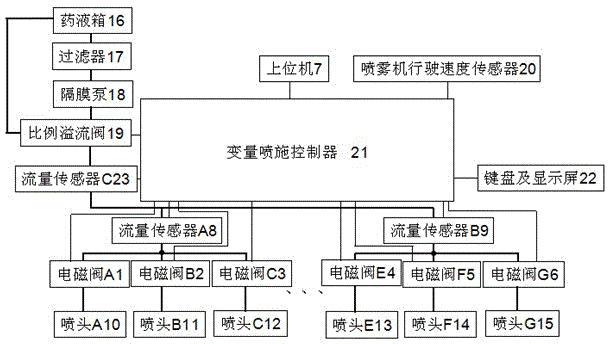

[0026] Such as figure 1 As shown, the PWM intermittent spraying variable spraying system consists of a pipeline subsystem and a control subsystem. The pipeline subsystem is supplied by a diaphragm pump 18, and the spray boom is divided into a plurality of identical spray boom sections. The liquid medicine tank 16, the filter 17, the diaphragm pump 18, and the proportional overflow valve 19 are connected sequentially through pipelines, the liquid outlet of the proportional overflow valve 19 is connected to the main pipeline of the spray rod, and the overflow port of the proportional overflow valve 19 passes through the pipeline. The road is connected back to the liquid medicine tank 16. Nozzle A10, Nozzle B11 and Nozzle C12 are in the same boom section, and the front-end pipelines are respectively equipped with solenoid valve A1, solenoid valve B2 and solenoid valve C3 in series, and the other ends of solenoid valve A1, solenoid valve B2 and solenoid valve C3 pass through The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com