Milling Chatter Control Method Based on Asymmetric Stiffness Regulation of Spindle System

A control method, milling chatter technology, applied in manufacturing tools, metal processing equipment, measuring/indicating equipment, etc., can solve the problems of weakening damping effect, shortening tool life, scrapping of workpieces, etc., to achieve energy saving, large milling stability area , The effect of the control method is simple and easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

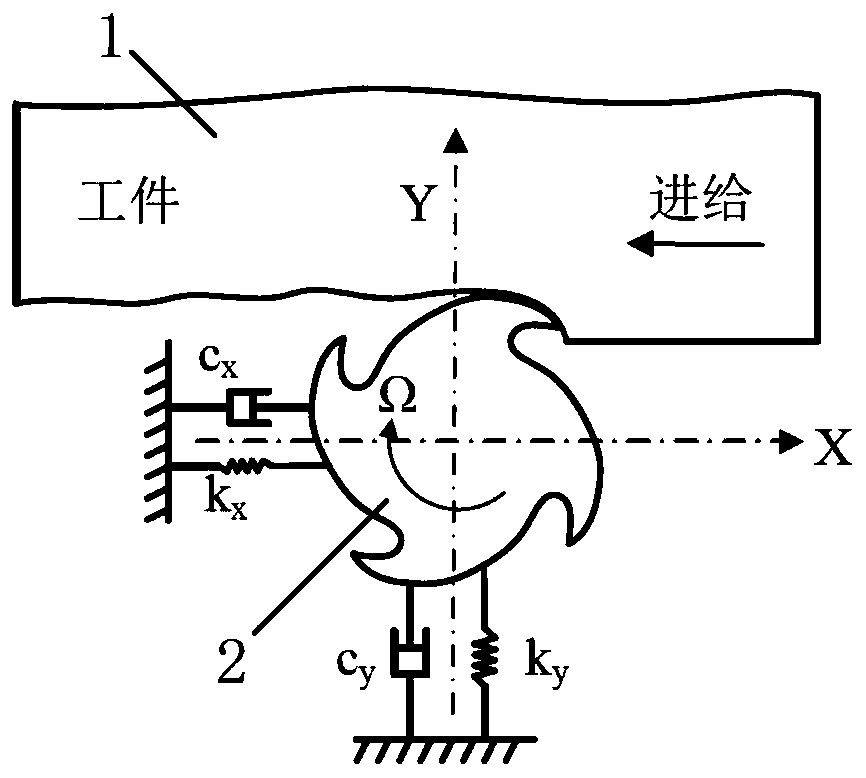

[0073] Implementation examples of the present invention adopt such as Figure 4 The milling spindle system shown is analyzed.

[0074] Using a 10mm-diameter 3-blade milling cutter, take the milling cutter tip as the origin of the coordinate axis, take the milling feed direction as the X-axis direction, and take the direction perpendicular to the feed direction and the tool axis as the Y-axis direction to establish two degrees of freedom Cartesian coordinate system.

[0075] Arrange an acceleration sensor along the X-axis direction at the tip of the milling cutter, use a force hammer to excite the tip of the milling cutter on the opposite side of the sensor, measure the frequency response function curve, and identify the modal mass m of the main mode x , stiffness k x and damping c x . Perform the same operation in the Y-axis direction to identify the modal mass m y , stiffness k y and damping c y . The results of modal parameter identification are shown in Table 1.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com