Preparation method of silicon dioxide aerogel composite material

A composite material and silicon dioxide technology, applied in chemical instruments and methods, colloid chemistry, colloid chemistry, etc., can solve the problems of high aerogel content, large consumption of organic solvents, and low aerogel content of composite materials, and achieve The effect of thorough modification, saving input and improving the utilization rate of solvent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

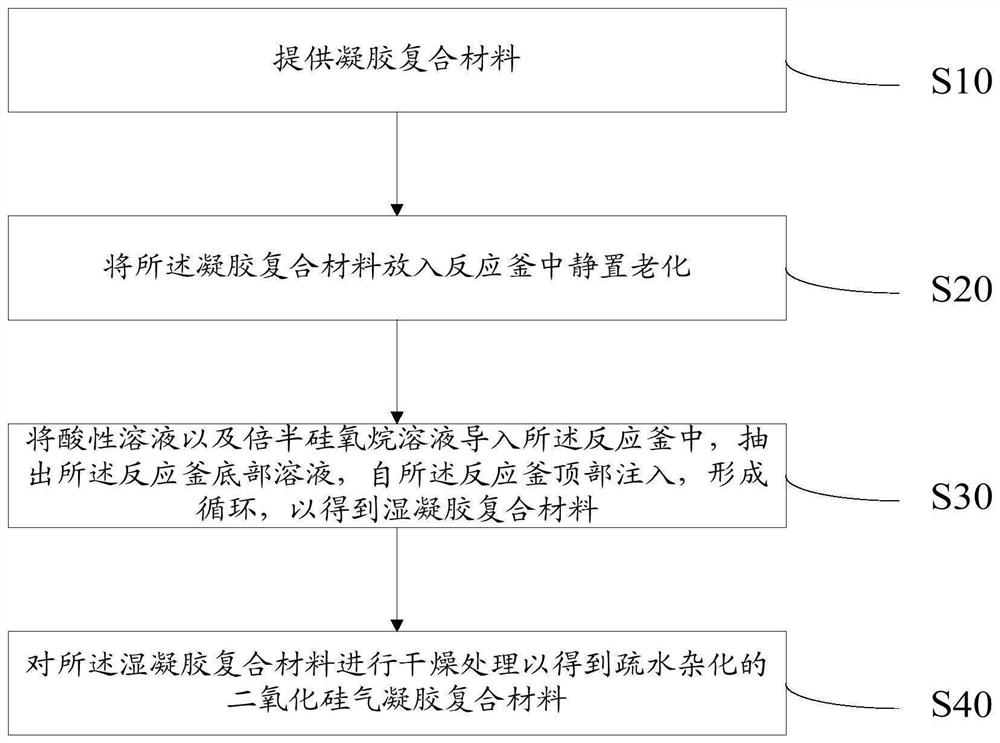

[0053] combine figure 1 Shown, in one embodiment, the preparation method of described silica airgel composite material comprises the following steps:

[0054] S10, providing a gel composite material;

[0055] This step mainly prepares gel composite materials, which can be purchased or prepared by yourself. When preparing by yourself, specifically, before step S10, it also includes:

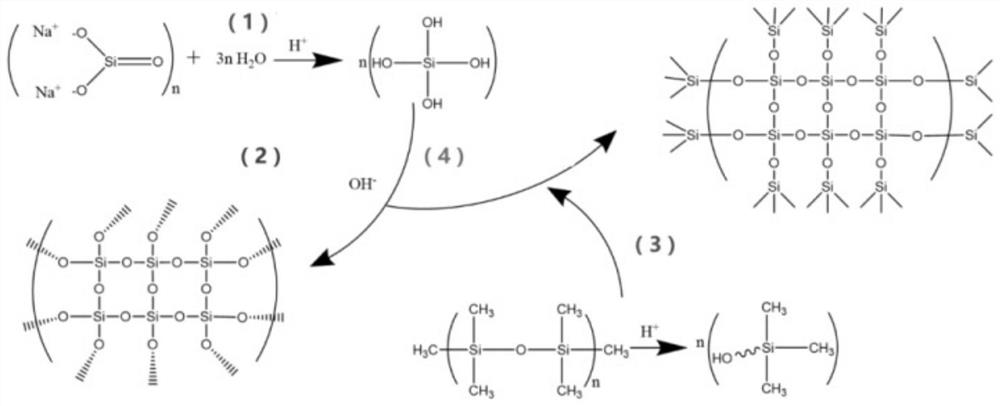

[0056] S101, mixing and stirring the silicon source and water to form a silicon source aqueous solution, adding an acidic aqueous solution to the silicon source aqueous solution for acidification to obtain a silicon sol solution;

[0057] Specifically, the silicon source includes that the solute is one or more of tetraethyl orthosilicate, tetramethyl orthosilicate, methyltrimethoxysilane, dimethyldimethoxysilane, and silicon tetrachloride. The aqueous solution of the species, the time of the acidification treatment is 5-60min, the temperature of the acidification treatment is 10-70°C, the silico...

Embodiment 1

[0092] (1) First dilute the sodium silicate aqueous solution with water, take 0.6L of sodium silicate aqueous solution and 3L of water, mix well and stir evenly, and obtain the dilution solution of the silicon source. Slowly introduce the diluent of the silicon source into 216mL of 8.5mol / L hydrochloric acid solution for acidification treatment, the time of the acidification treatment is 5min, and the temperature of the acidification treatment is 70°C to obtain a sol solution;

[0093] (2) Add 2.5M ammonia solution to the silica sol solution, mix and stir to adjust the pH of the sol to 4.6, and introduce it into the fiber composite material. After the sol solution is fully impregnated, when the fiber composite material is solidified, microwave The gel composite material was obtained by irradiation treatment, the irradiation power per 400mL of silica sol solution was 0.6KW, and the treatment time was 125s;

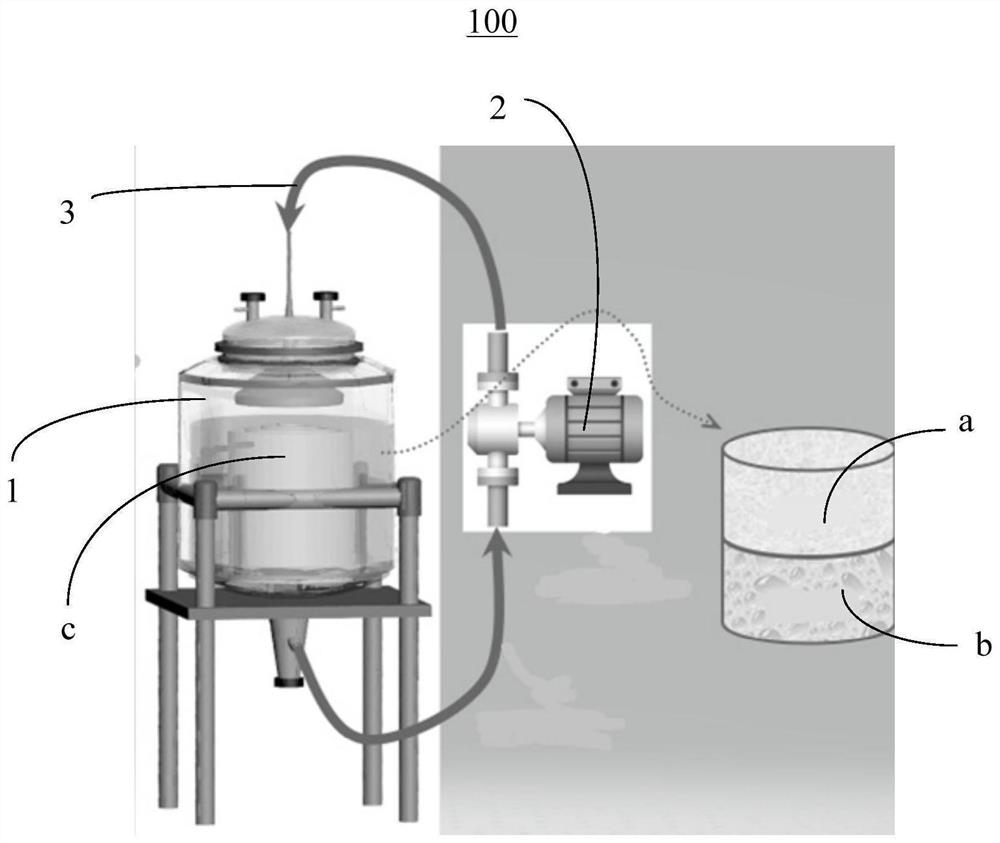

[0094] (3) Put the gel composite material into a reactor to stand for ...

Embodiment 2

[0099] (1) First dilute the sodium silicate aqueous solution with water, take 1.34L of silicon source and 2.95L of water, mix well and stir evenly to obtain the dilution of silicon source. Slowly introduce the diluent of the silicon source into 650 mL of 4.8M hydrochloric acid solution for acidification treatment, the time of the acidification treatment is 60 minutes, and the temperature of the acidification treatment is 10°C to obtain a sol solution;

[0100] (2) Adjust the pH of the sol to 5.0 with a diluted sodium silicate aqueous solution, wherein the volume ratio of the silicon source to water is 0.2-8:1, stir evenly, and introduce it into the fiber composite material, and wait until the sol solution is fully impregnated Finally, when the fiber composite material is solidified, the gel composite material is obtained by microwave irradiation treatment, the irradiation power of each 400mL silica sol solution is 0.4KW, and the microwave irradiation treatment time is 45s.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com