Method for producing active carbon

A production method and technology of activated carbon, applied in the production field of activated carbon, can solve the problems of increasing production cost, prolonging the production cycle, and high production cost, and achieve the effect of reducing water consumption, reducing production cost, and good quality of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

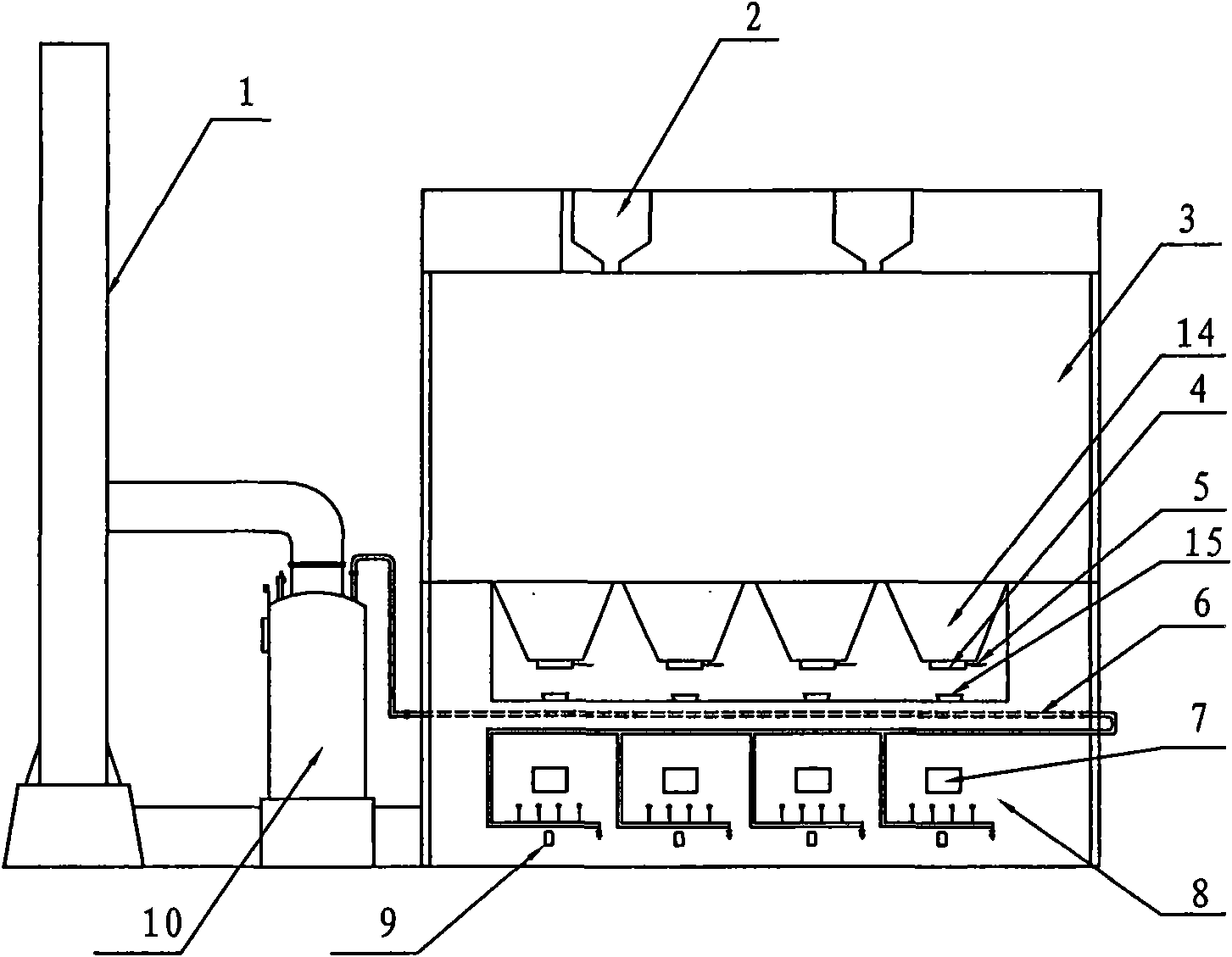

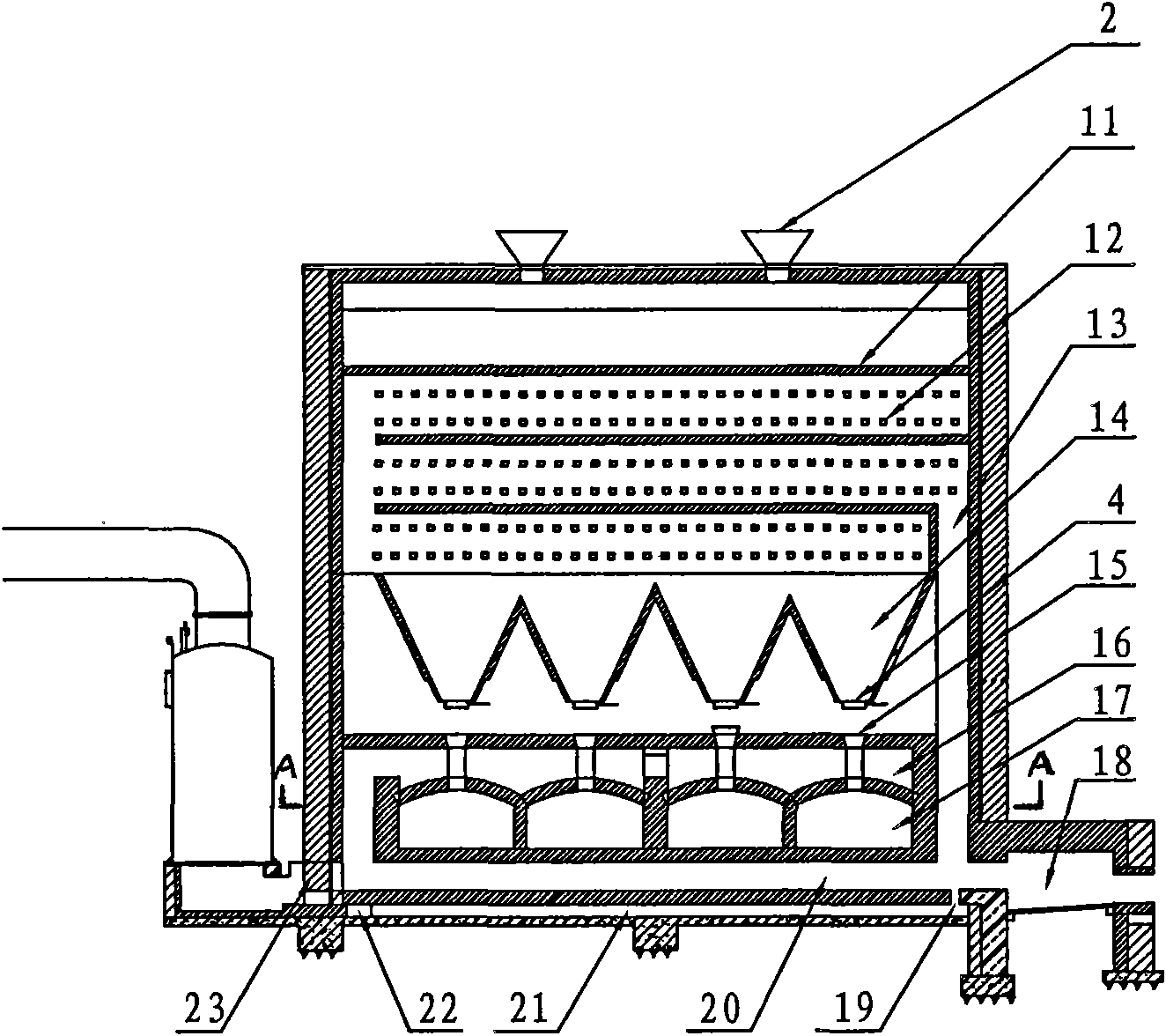

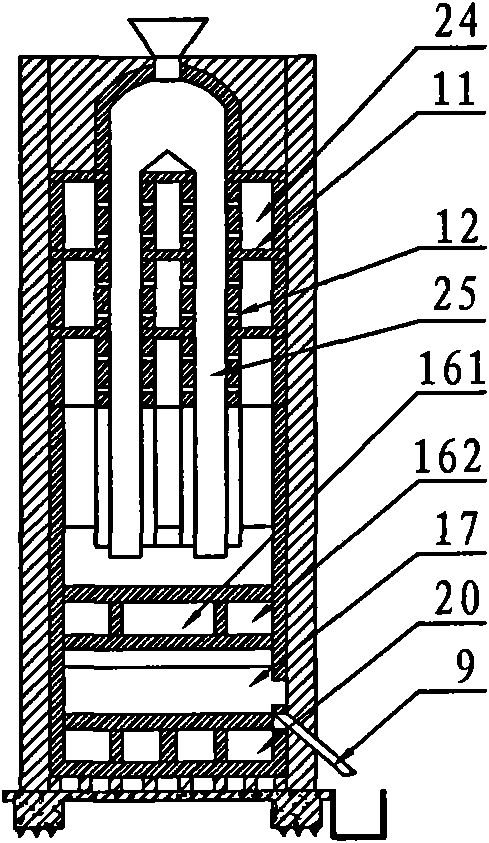

[0024] Such as figure 1 Shown, the kiln that implements the production activated carbon of the inventive method comprises carbonization kiln and activation kiln two major parts, and carbonization kiln is positioned at the top of activation kiln, and carbonization kiln is made of carbonization kiln body 3, feed port 2 above carbonization kiln body, carbonization kiln body The discharge port 4 below is formed, and the discharge port is equipped with a flashboard 5 for controlling discharge. The activation kiln is composed of an activation kiln body 8, a feed inlet 15 on the upper part of the activation kiln body, a discharge port 9 on the lower part of the activation kiln body, a kiln door 7 and a steam pipeline 6. There is also an activation kiln on the outside of the kiln. With the steam boiler 10 of steam, the pipeline 6 that sends the steam produced by the boiler into the activation chamber passes through the flue at the top of the activation chamber. The discharge port 4 o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com