Biological deodorization composition for odor removal, method for preparing filler by biological deodorization composition and application of biological deodorization composition

A technology of biological deodorization and deodorizing fillers, which is applied in gas treatment, air quality improvement, chemical instruments and methods, etc., can solve the problems of poor air permeability and easy clogging of biological deodorizing fillers, and achieve excellent water holding capacity and bio-affinity high moisture retention and strong corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] 27 parts of decomposed sludge, 63 parts of biochar, 3 parts of cement, 7 parts of blast furnace slag and 67 parts of water were mixed, dried naturally, pressed and molded to make fillers, and the fillers with a particle size of 3 cm were selected to be placed in the experiment. Biological deodorization box, the height of the deodorization box is 1.2m, the inner diameter is 0.3m, the upper part is equipped with a spray device, the lower part is equipped with a water collection device, the effective height of the control filler is 0.8m, and the odor generated by sludge drying is introduced to control the inlet Volume 1.8m 3 / h, the residence time is 30s, the experimental device runs continuously for 20 days, and no nutrients are added during the experiment. Three groups of parallel experiments were set up, the discrete values were removed from the test results, and the average value was taken. The experimental results are shown in Table 1 after determination:

Embodiment 2

[0054] Compared with Example 1, the difference is that the filler used is a mixture of decomposed sludge and biochar with a weight ratio of 1:3. The experimental results are as shown in Table 1:

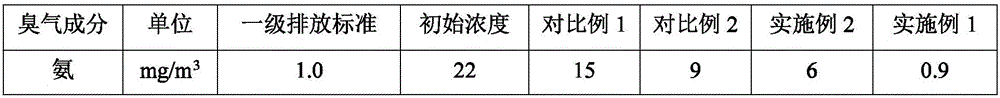

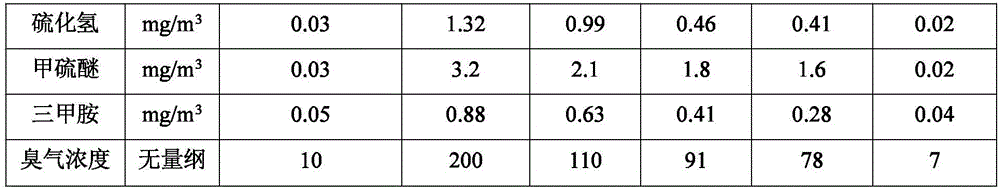

[0055] Table 1

[0056]

[0057]

[0058] After the above conditions, when the comparative example 1 runs to 14 days, the porosity decreases, the air permeability decreases, and the deodorization ability decreases; when the comparative example 2 runs to 10 days, the filling height is only one-third of the initial height as the spray liquid is gradually lost 1. The deodorization ability is obviously reduced; when the operation of Example 2 reaches 20 days, part of the filler is lost with the spray liquid, the pressure drop of the filler is obviously increased, and the deodorization efficiency is reduced; the deodorization effect of Example 1 is good during the operation period, and the filler is not broken The phenomenon of cracking, the growth of microorganisms is in good cond...

Embodiment 3

[0060] Mix 28 parts of decomposed sludge, 65 parts of biochar, 3 parts of cement, 7 parts of blast furnace slag and 68 parts of water, dry it naturally, press and shape it, and put the filler with a particle size of 3 cm into the experimental biological deodorization Deodorization box, the height of the deodorization box is 1.2m, the inner diameter is 0.3m, the upper part is equipped with a spray device, the lower part is equipped with a water collection device, the effective height of the control filler is 0.8m, and the odor generated by the sludge drying is introduced, and the air intake volume is controlled to be 1.8m. m 3 / h, the residence time is 30s, the experimental device runs continuously for 60 days, and no nutrients are added during the experiment. Three groups of parallel experiments were set up, the discrete values were removed from the test results, and the average value was taken. The experimental results are shown in Table 2 after determination:

[0061] Tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com