Dust removing device for vacuum cleaner

A technology of dust removal device and vacuum cleaner, which is applied in the direction of suction filter, etc., to achieve the effect of clean air and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

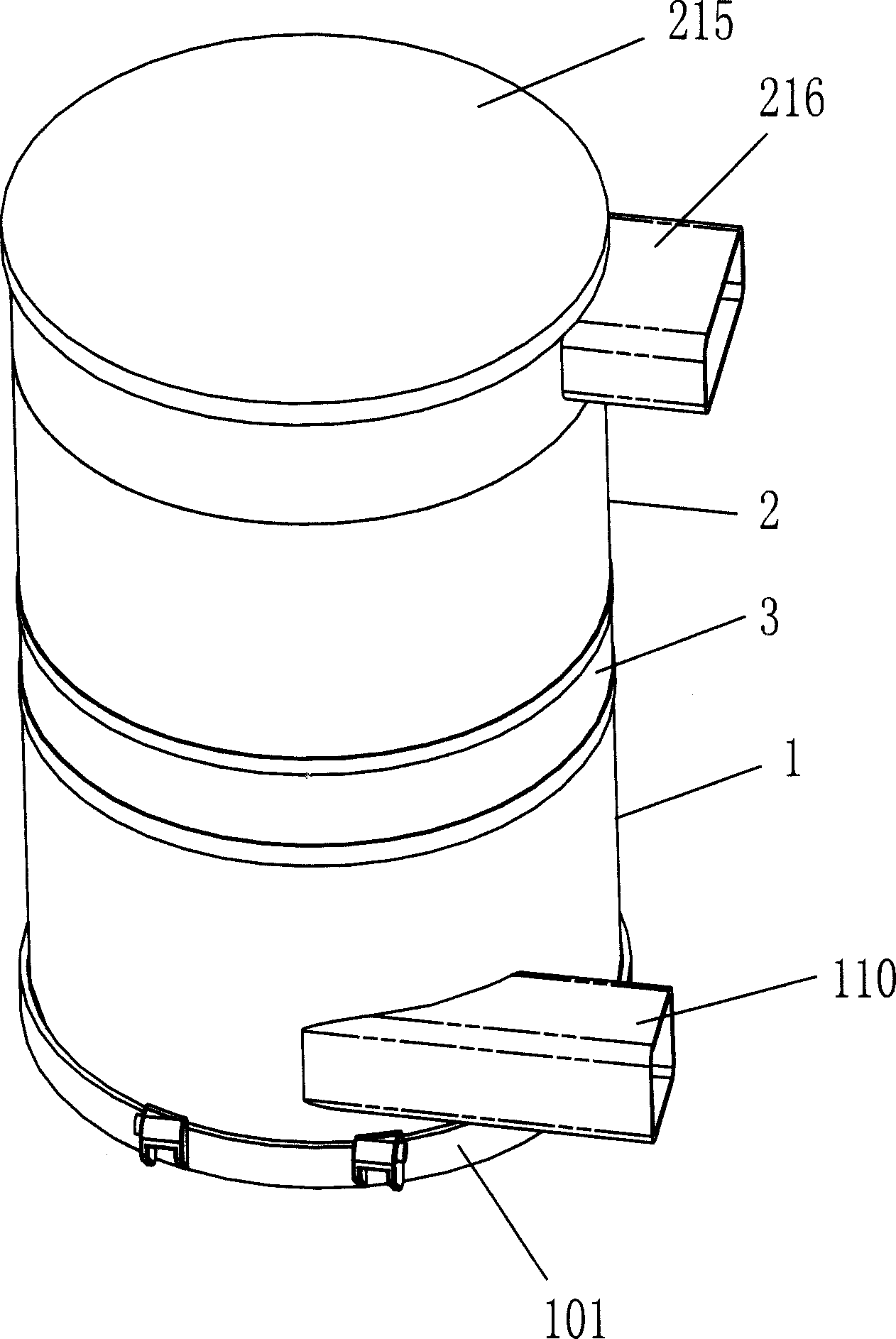

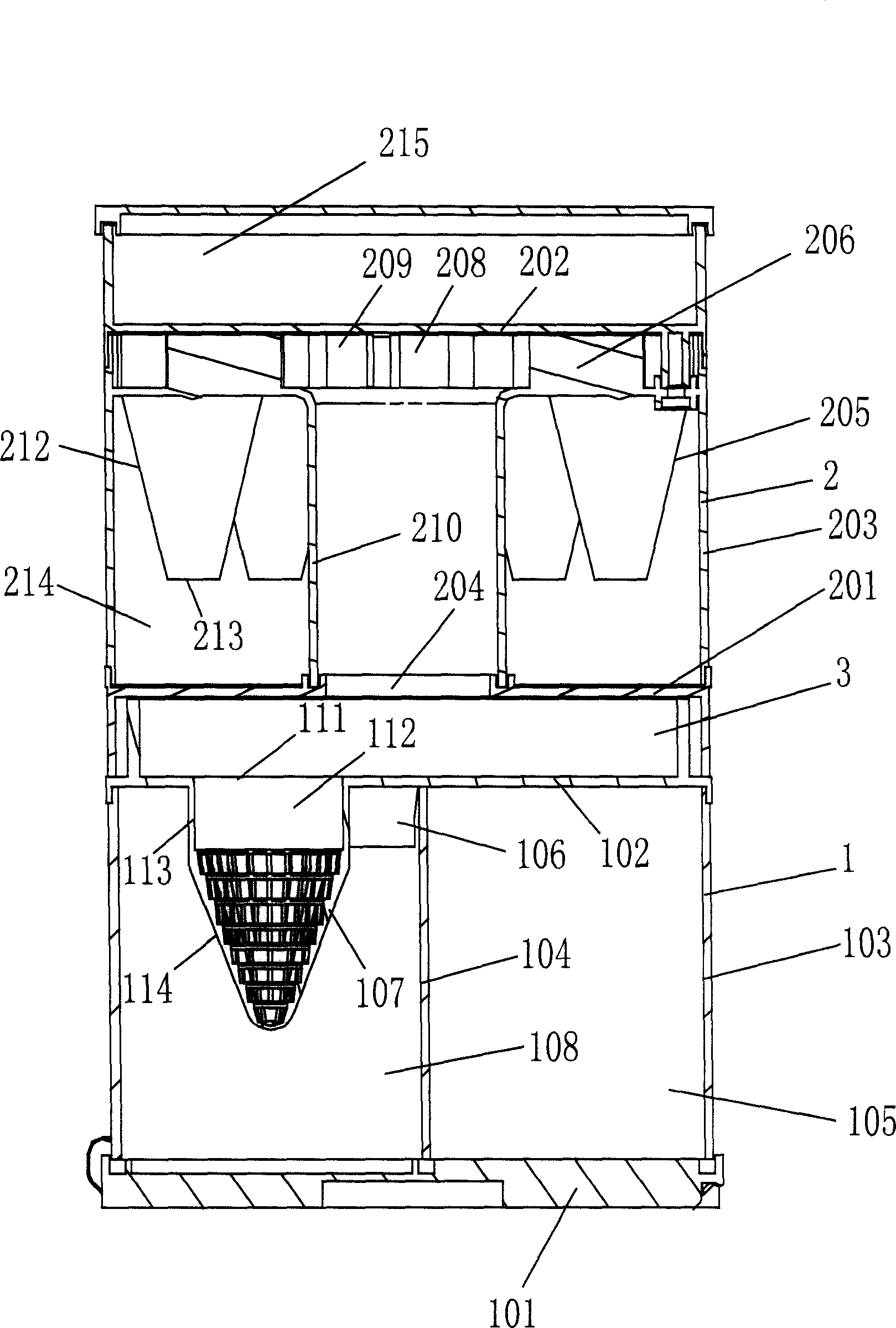

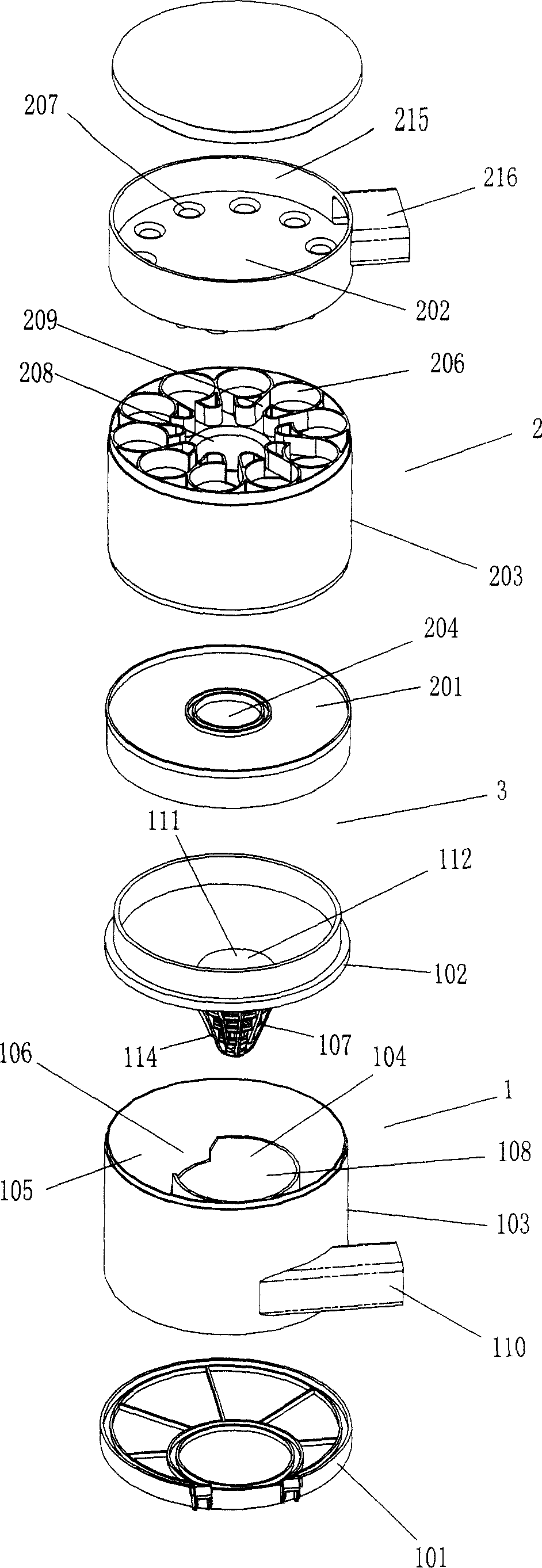

[0027] Embodiment one: if figure 1 , figure 2 , image 3 , Figure 4 As shown, a dust removal device for a vacuum cleaner includes a primary cyclone 1 and a secondary cyclone 2, the secondary cyclone 2 is located above the primary cyclone 1, and the air outlet of the primary cyclone 1 is connected to the secondary cyclone 1. The air inlet of the cyclone 2 is connected, and the primary cyclone 1 and the secondary cyclone 2 have independent dust collection chambers respectively.

[0028] The primary cyclone 1 includes an outer cylinder 103 with a bottom cover 101 and an upper cover 102, the outer cylinder 103 is provided with an inner cylinder 104, the inner cylinder 104 is eccentrically arranged in the outer cylinder 103, and the inner cylinder Between 104 and the outer cylinder 103 is the dust collection chamber 105 of the primary cyclone 1, the upper edge of the inner cylinder 104 is provided with a dust outlet 106 communicating with the dust collection chamber 105, and t...

Embodiment 2

[0032]Embodiment two: if figure 1 , Figure 5 , Figure 6 , Figure 7 As shown, a dust removal device for a vacuum cleaner includes a primary cyclone 1 and a secondary cyclone 2, the secondary cyclone 2 is located above the primary cyclone 1, and the air outlet of the primary cyclone 1 is connected to the secondary cyclone 1. The air inlet of the cyclone 2 is connected, and the primary cyclone 1 and the secondary cyclone 2 have independent dust collection chambers respectively.

[0033] The primary cyclone 1 includes an outer cylinder 103 with a bottom cover 101 and an upper cover 102, the outer cylinder 103 is provided with an inner cylinder 104, the inner cylinder 104 is eccentrically arranged in the outer cylinder 103, and the inner cylinder Between 104 and the outer cylinder 103 is the dust collection chamber 105 of the primary cyclone 1. The upper edge of the inner cylinder 104 is provided with a dust outlet 106 communicating with the dust collection chamber 105. The i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com