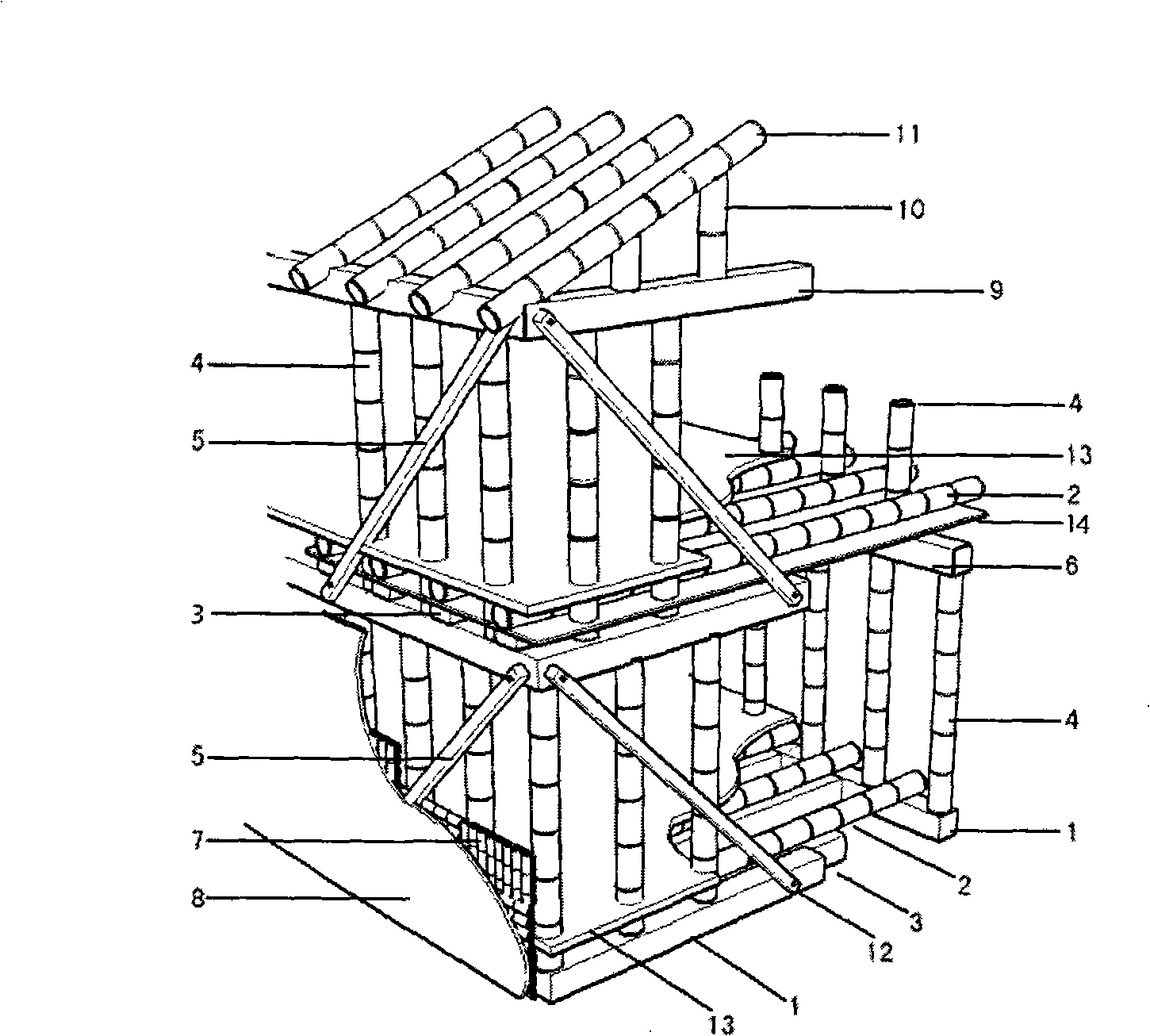

Bamboo-wood mixed structure of house architecture

A hybrid structure and building technology, applied in the direction of building structure, construction, etc., can solve the problem that bamboo buildings can only be used for temporary buildings and simple housing, lack and other problems, so as to reduce the economic burden of building construction, reduce the amount of use, and reduce the seismic performance. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

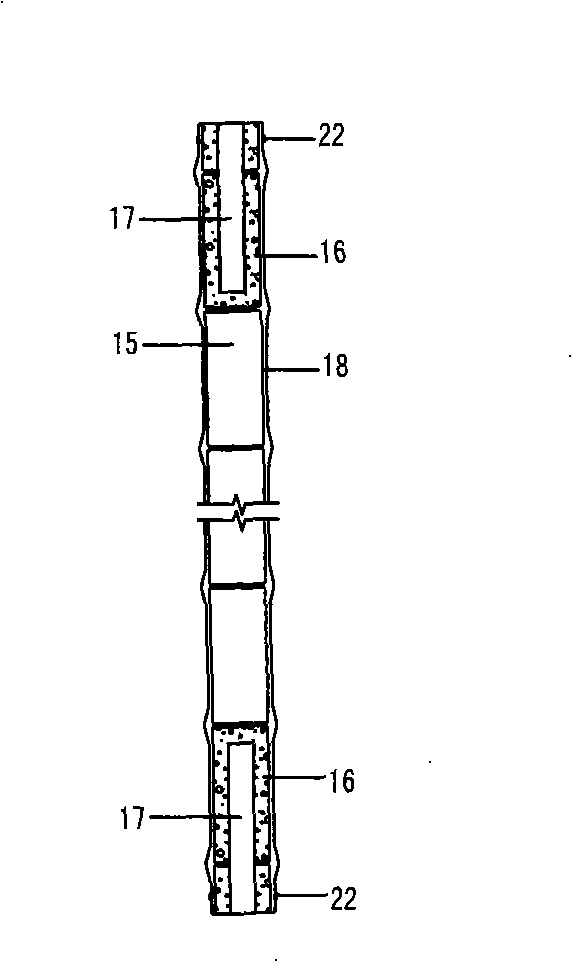

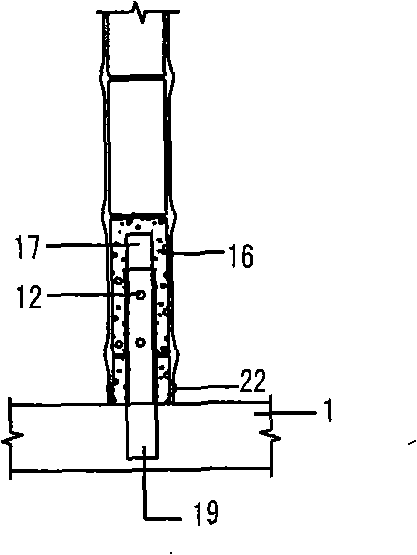

[0027] First the original bamboo is carried out anti-corrosion and anti-moth treatment, then the original bamboo is cut into the original bamboo rods of a certain length according to the needs of the building, and the steel plate 19 and the embedded bolt 20 are pre-embedded in the reinforced concrete ground beam 1 (such as Figure 8 , Figure 9 shown), fill the cavity filler 16 in the cavity at both ends of the original bamboo column 4, and plug it into the core column 17 ( image 3 ), after the cavity filler 16 reaches the design strength, slot the lower end of the original bamboo column 4, snap into the embedded steel plate 19, drill holes at the corresponding position of the lower end of the original bamboo column 4 and the opening on the embedded steel plate 19, and use a fixed After the bolt 12 runs through the above-mentioned opening, the two ends are tightened with nuts, so that the original bamboo column 4 is fixed on the reinforced concrete ground beam 1 (see image ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com