Halogen-free low-warpage low-linear-expansion-coefficient extrusion-grade thin-wall flame-retardant polycarbonate composite material and preparation method thereof

A flame retardant polycarbonate and linear expansion coefficient technology, applied in the field of polycarbonate resin composite materials, can solve problems such as reducing the linear expansion coefficient, and achieve the effects of improving melt strength, low production cost, and ensuring dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

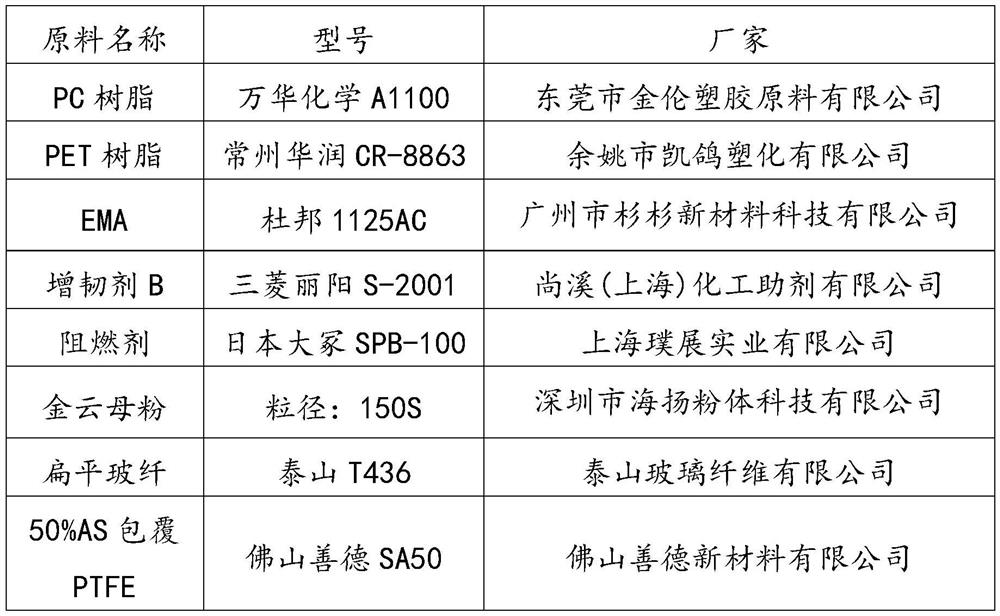

Method used

Image

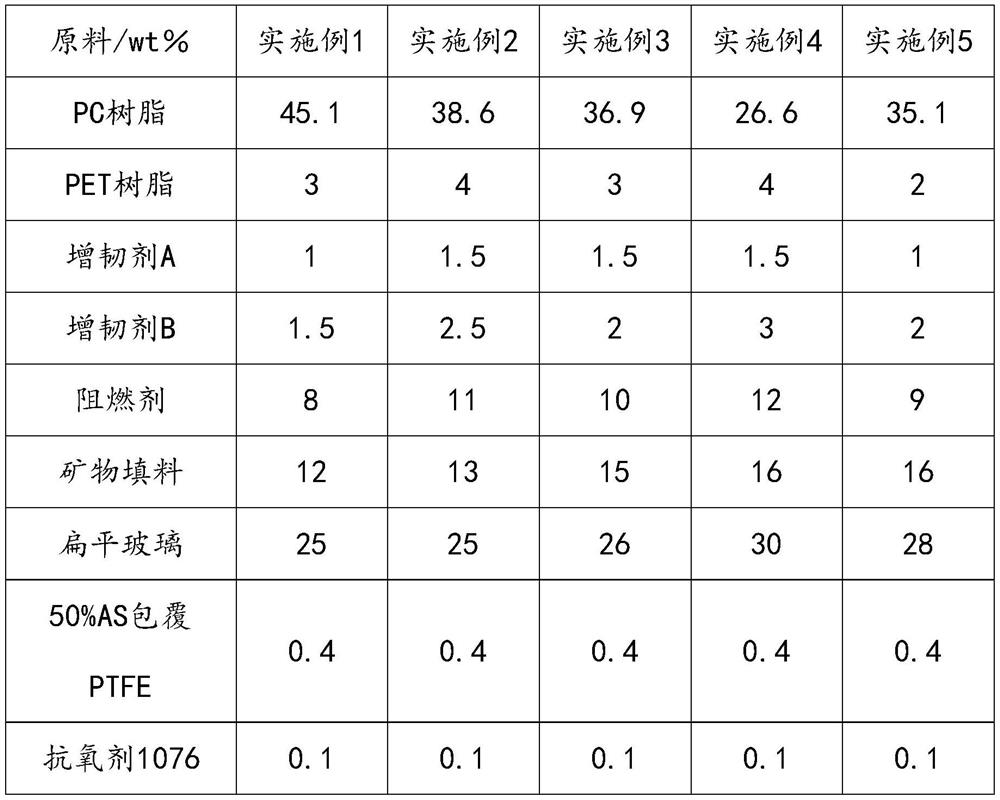

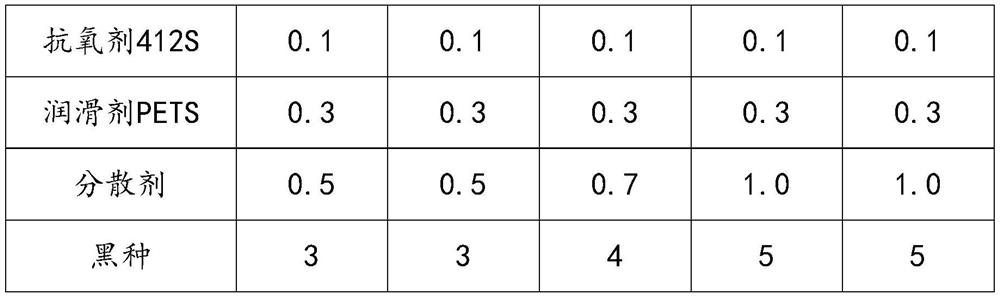

Examples

preparation example Construction

[0044] The preparation method of the polycarbonate composite material of Examples 1 to 5 is as follows: place the PC resin at 120° C. for 4 hours to dry until the water content of the PC resin is lower than 0.02%, and then weigh it according to the mass percentage of each component in the formula Take each raw material and add it to a high-speed mixer, adjust the speed of the mixer to 500r / min, stir for 5 minutes, then transfer the material in the high-speed mixer to a twin-screw extruder, adjust the processing temperature of the twin-screw extruder to 240°C, and the screw speed Be 300rpm / min, extrude, granulate, promptly obtain the polycarbonate composite material of embodiment 1~5; Or,

[0045] Dry the PC resin at 130°C for 4 hours until the water content of the PC resin is lower than 0.02%, then weigh each raw material according to the mass percentage of each component in the formula and add it to a high-speed mixer, and adjust the speed of the mixer to 500r / min , stir for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com