Trench steel cover board component

A steel cover plate and trench technology, applied in water conservancy projects, artificial islands, underwater structures, etc., can solve the problems of large cover plate gaps, large differences in single cover plates, and unsafety, and achieve reasonable cross-sectional mechanical properties, High bending rigidity and comfortable foot feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

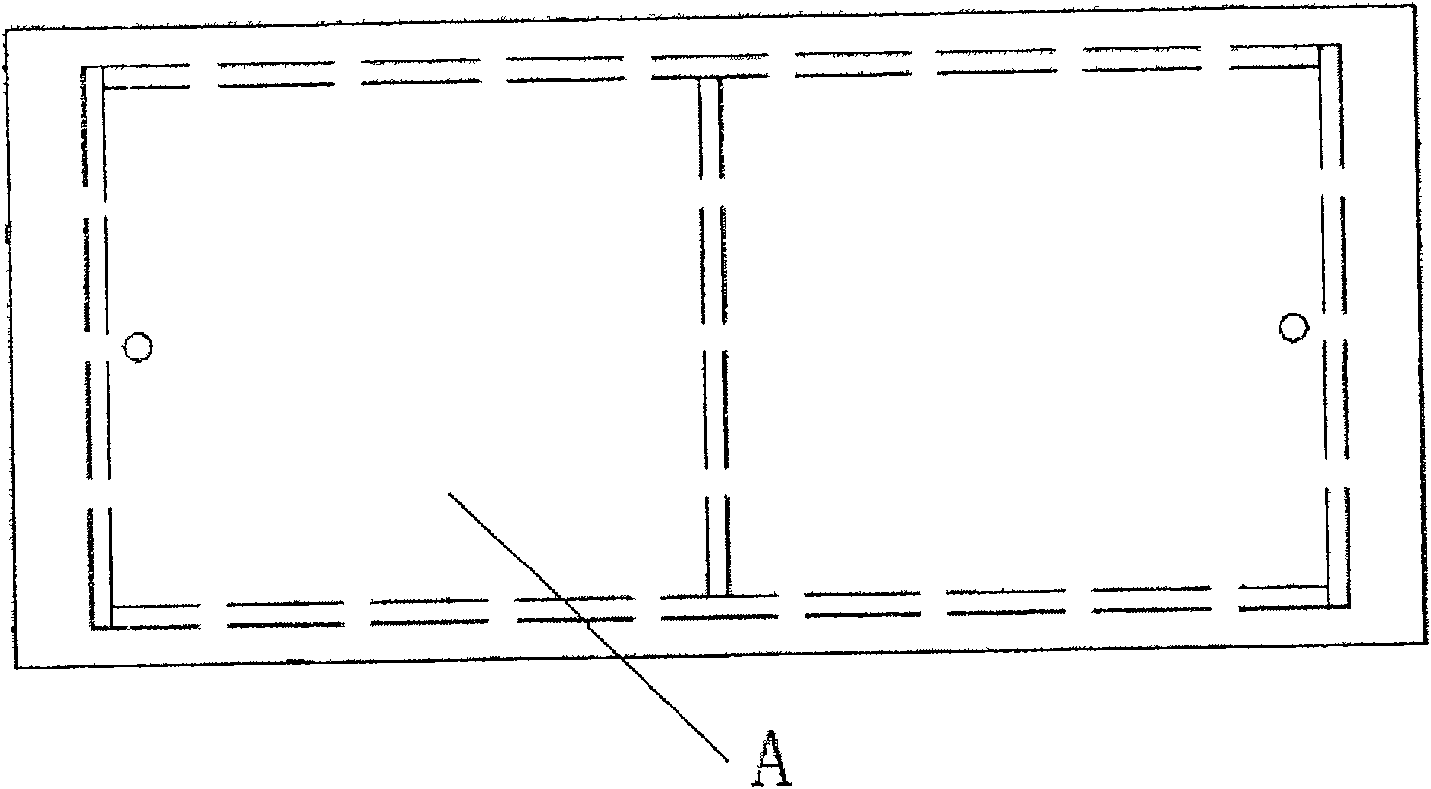

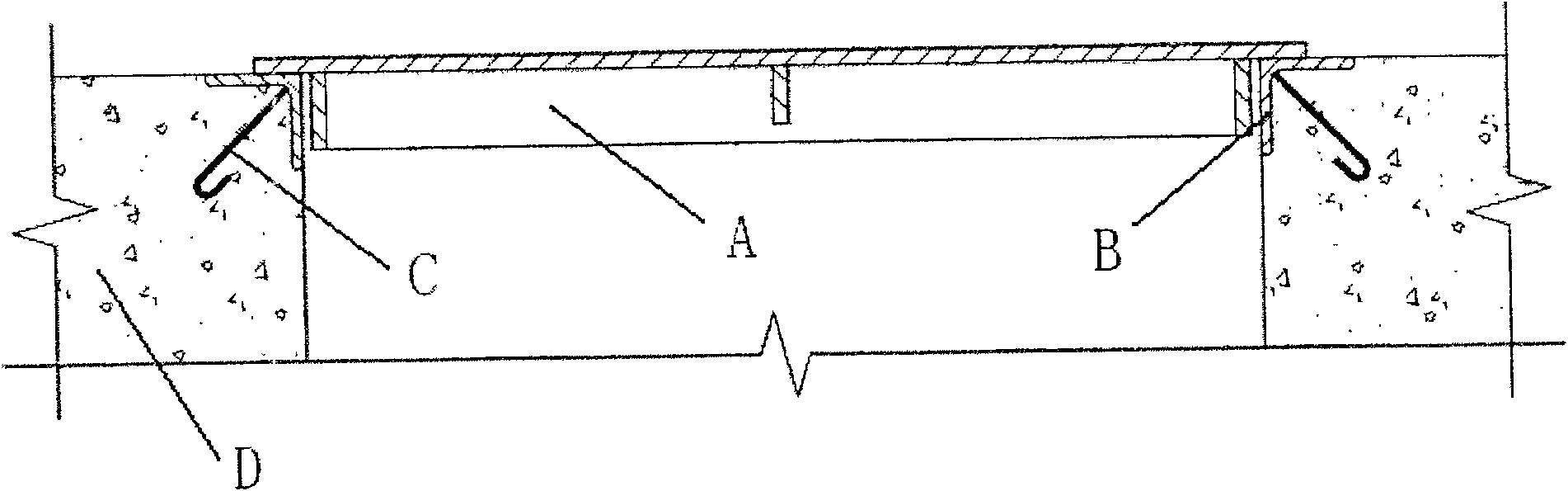

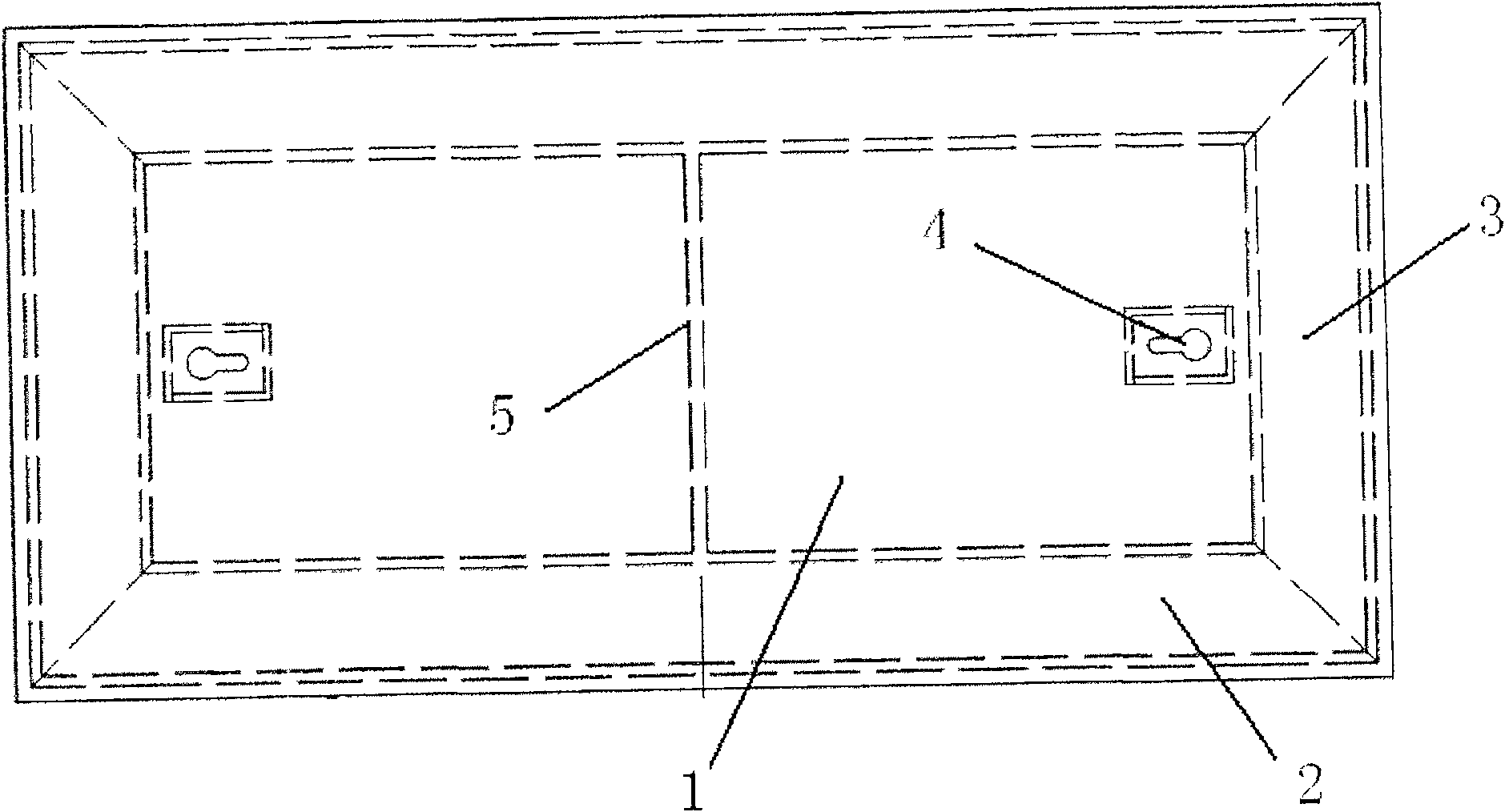

[0020] Embodiment one, as Figure 3-4 As shown, this embodiment includes a pair of sunken corner protectors 7 and a steel cover plate 1 placed on them. The sunken corner protectors 7 are a group of angle steels, which are respectively fixed on the trench surface and the sunken surface. . The angle steel located on the sinking surface has a sinking degree equivalent to the thickness of the steel cover plate 1 . An anchor bar 8 is also provided on the corner protector 7; the anchor bar is anchored in the concrete. The steel cover plate 1 includes two supports 3 placed on the corner protector 7 , two rib beams 2 connecting the supports 3 , and a top plate 6 fixed on the supports 3 and the rib beams 2 . A stiffening rib 5 is also provided between the two rib beams 2 . The steel cover plate 1 is usually welded by Q235-B grade hot-rolled steel and cold-formed thin-walled steel. In this embodiment, the support 3 is a square tube steel, and the rib beam 2 is a rectangular or squar...

Embodiment 2

[0021] Embodiment 2. The difference from Embodiment 1 is that an elastic rubber pad 9 is provided on the sinking surface of the corner protector, such as Figure 9 Shown; to prevent the sound of "gudong, gudong" when stepping on it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com