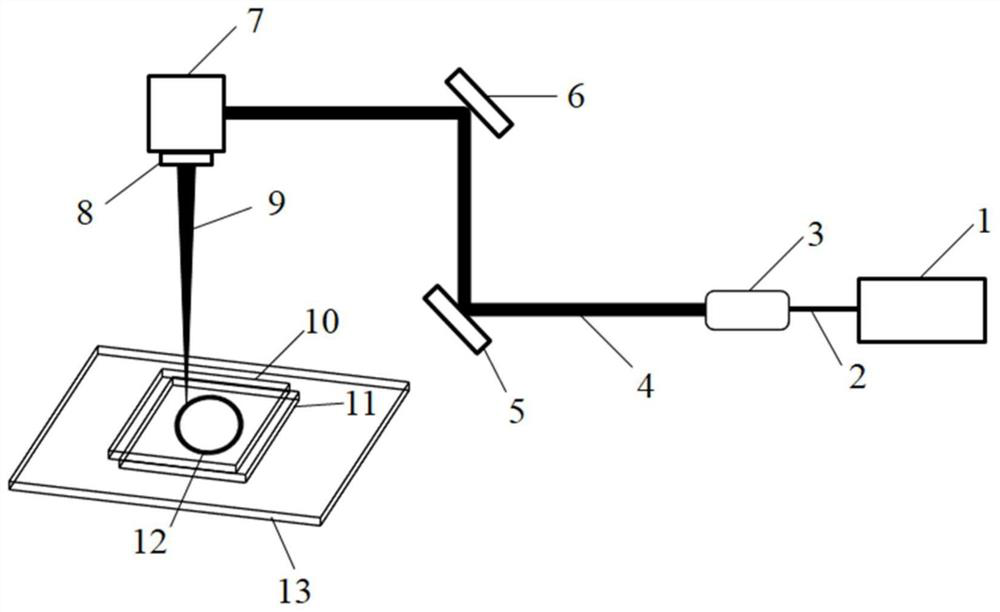

Femtosecond laser glass welding device and method

A femtosecond laser and glass technology, used in glass forming, glass remolding, glass manufacturing equipment, etc., can solve the problems of inability to weld thick materials, small focus, discontinuous welding points, etc., and meet the requirements of low glass surface. , The effect of reducing the generation of micro-cracks and shortening the welding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

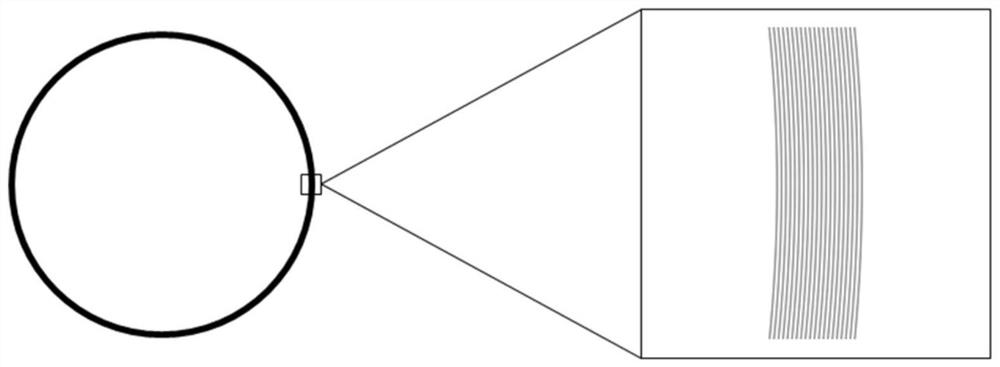

[0041] Use a femtosecond laser with an output wavelength of 1030nm, a pulse width of 450fs, a maximum output power of 10W, and a repetition rate of 100-300KHz to weld two pieces of quartz glass with a thickness of 0.5-3mm stacked with anhydrous ethanol, two pieces of glass The gap between them is 5-10 μm. The femtosecond laser is focused on the contact surface between two pieces of glass, the laser power of the target surface is set to 4-6W, the pulse repetition frequency is 100-200KHz, and the scanning distance is 0.01-0.05mm at a speed of 100-300mm / s. figure 2 Concentric circle path; then change the laser power of the target surface to 6-8W, adopt a pulse repetition frequency of 200-300KHz, and scan along the same path at a speed of 7-30mm / s. The welding results show that the glass melts evenly at the weld, has good waterproof and sealing performance, the shear strength is greater than 40MPa, and there is no trace of damage on the glass surface.

Embodiment 2

[0043] On the basis of the above-mentioned Example 1, further, water was used instead of absolute ethanol to drip in the glass gap, and the welding results showed that the glass melted evenly at the welding seam, the waterproof sealing was good, and there was no damage mark on the glass surface.

Embodiment 3

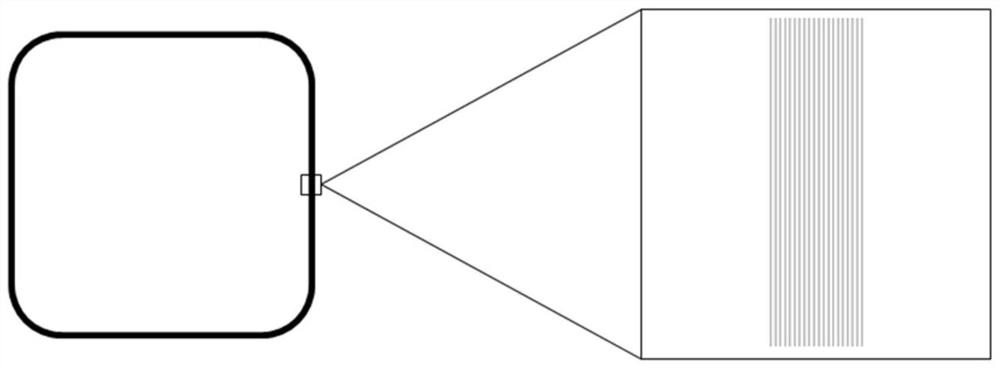

[0045]On the basis of above-mentioned embodiment 1, further, adopt image 3 Rectangular paths with concentric rounded corners instead figure 2 The concentric circle path, the welding results show that the glass melts evenly at the welding seam, the waterproof and sealing performance is good, and there is no trace of damage on the glass surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com