Gel strip pasting machine

A technology of gluing machine and gluing mechanism, which is applied in the directions of sending objects, processing of thin materials, transportation and packaging, etc., can solve the problems that the efficiency cannot reach the efficiency of the project, it is not cost-effective, and the single-sided plastic frame gluing cannot be applied.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing:

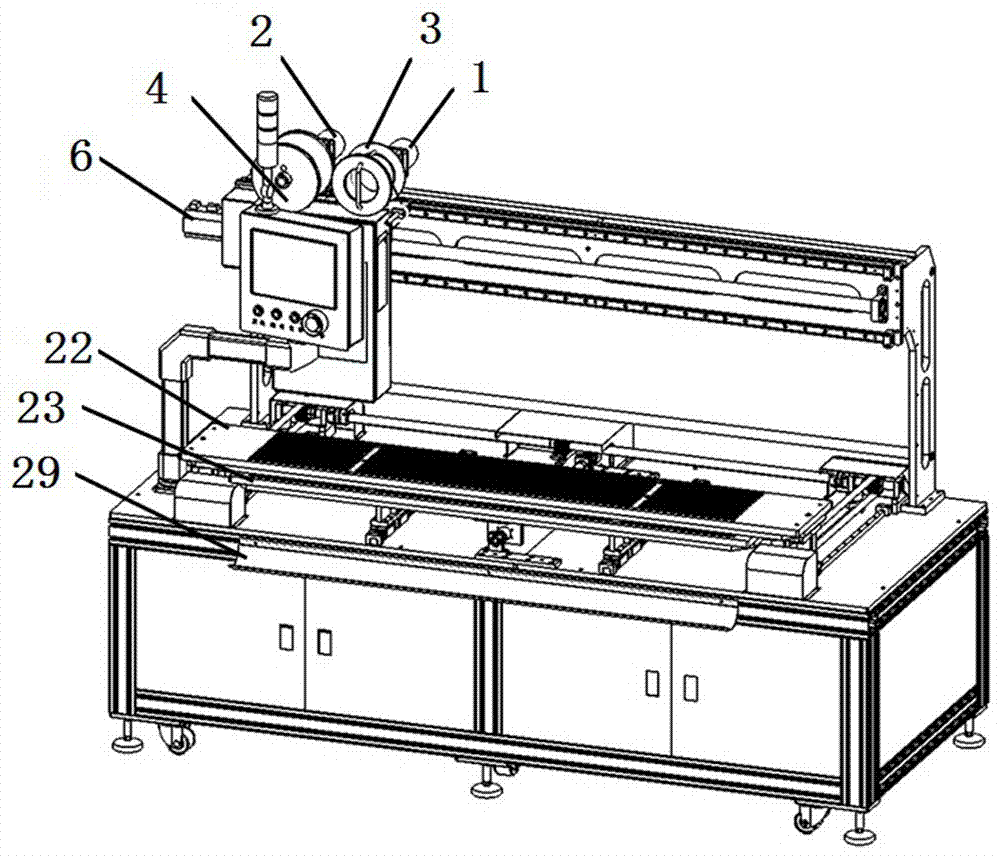

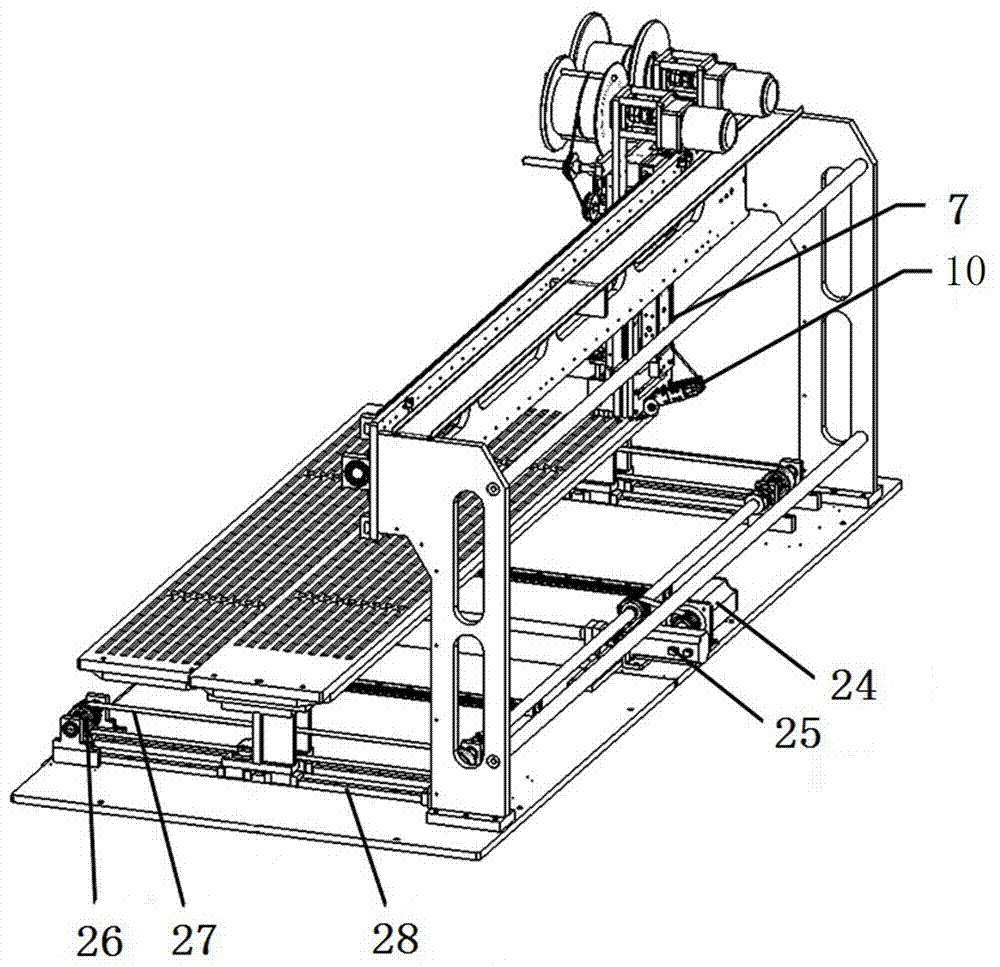

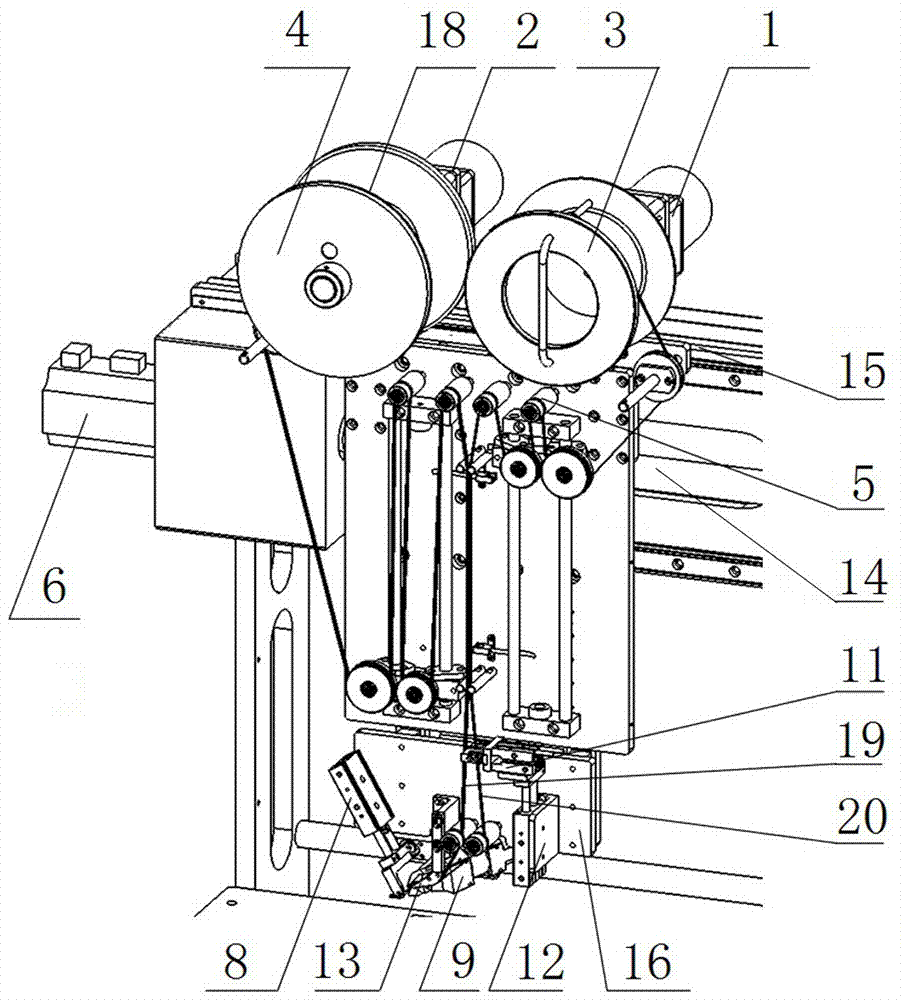

[0028] The gluing machine is characterized in that it includes a gluing mechanism and a jig mechanism;

[0029] The gluing mechanism includes a rewinding motor (1) and an unwinding motor (2), a rewinding reel (3) and an unwinding reel (4), several tension adjustment wheels (5), and a glue displacing motor (6) , Upper and lower cylinders for glue application (7), rolling cylinders (8), glue cutting air shears (9), glue cutting cylinders (10), release paper clamping cylinder Ⅰ (11), release paper clamping cylinder Ⅱ (12) , Laminating groove (13);

[0030] The winding motor (1) and the unwinding motor (2), the winding reel (3) and the unwinding reel (4) are arranged on the glue sticking module (14), and the glue sticking module (14) passes through The slide block is movably arranged on the horizontal slide rail (15), and the gluing module (14) is provided with a gluing shift...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com