Totally-enclosed type linear module

A linear module and fully enclosed technology, applied in the field of linear transmission, can solve problems such as low transmission efficiency, poor stability, and easy upturning of the sealing steel belt, and achieve high transmission efficiency, high sealing strength, and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

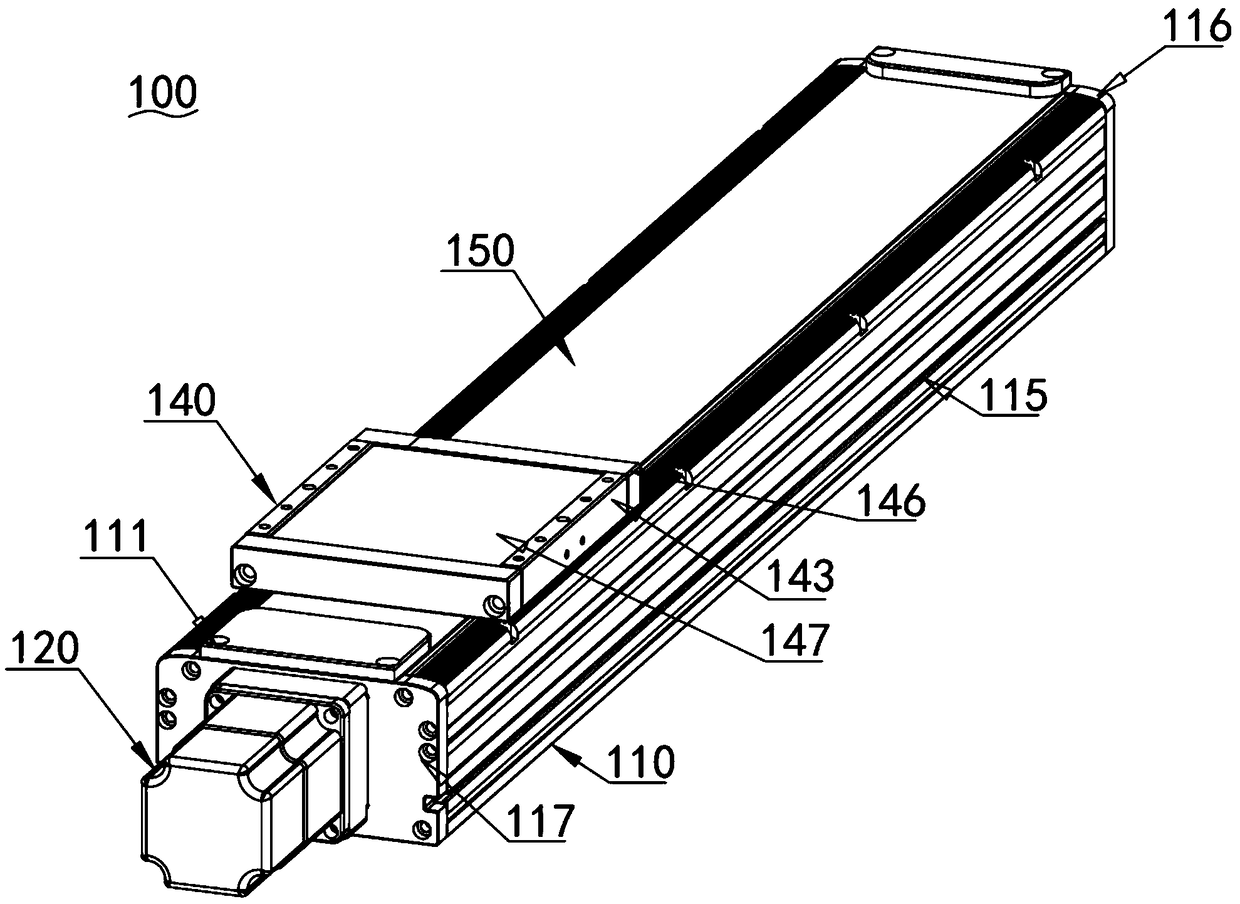

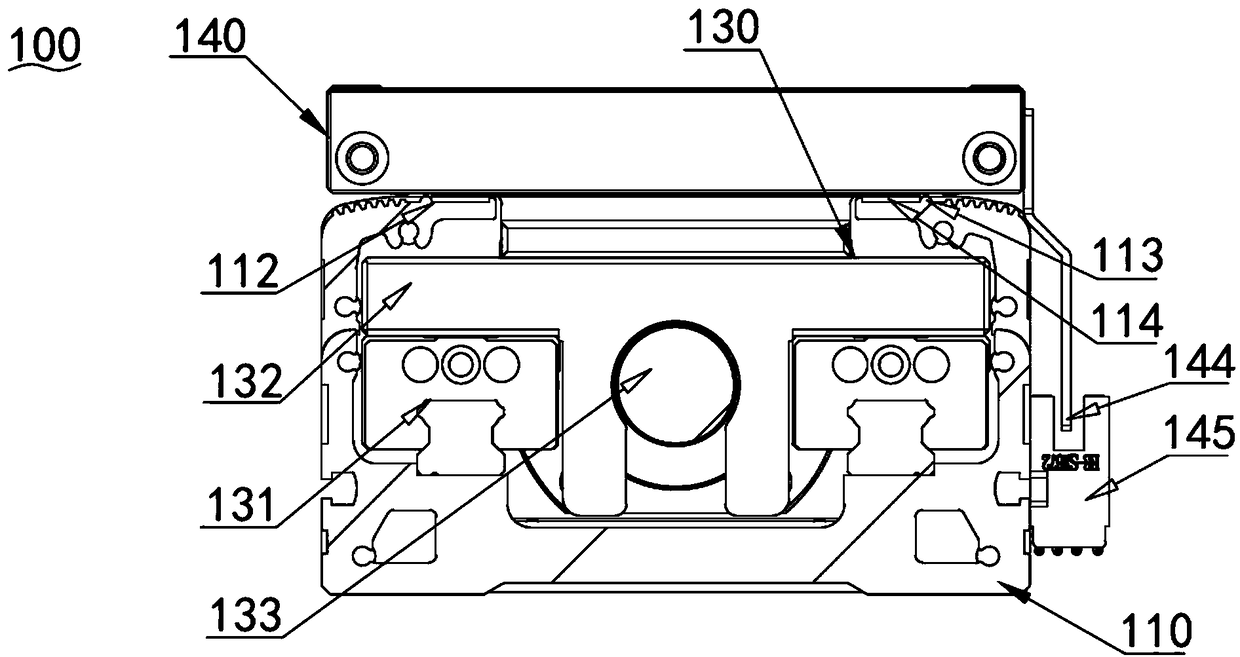

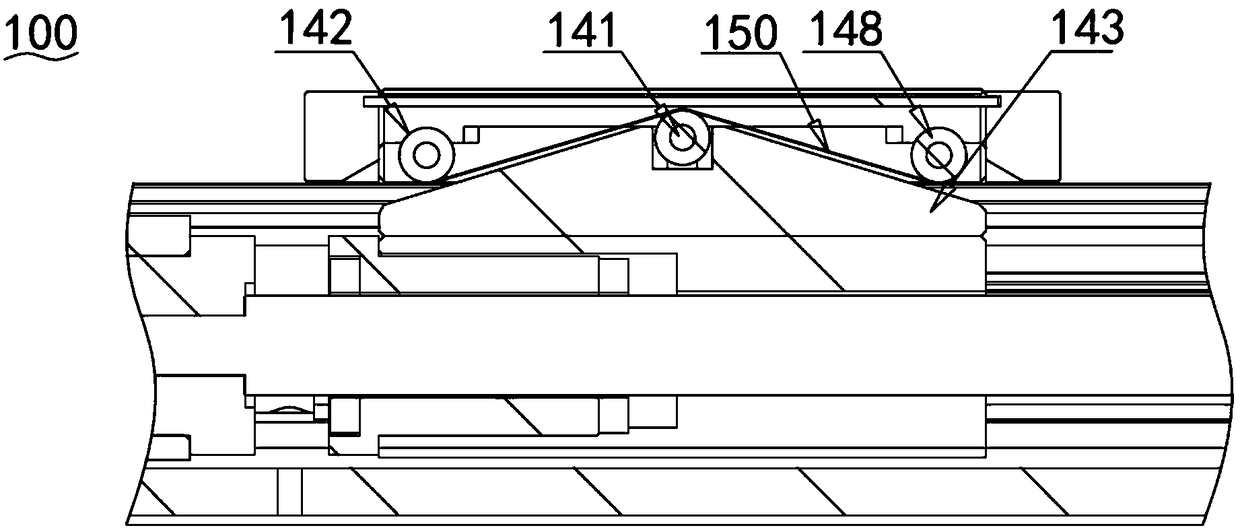

[0022] Such as Figure 1 ~ Figure 3 As shown in FIG. 1 and 2 , respectively, are the three-dimensional schematic diagram of the linear module of the present invention and the cross-sectional schematic diagrams of different viewing angles.

[0023] A fully enclosed linear module 100, comprising a base 110, a drive assembly 120 disposed at one end of the base 110, a transmission component 130 disposed inside the base 110 and drivingly connected to the drive assembly 120, and a transmission seat 140 movably disposed on the transmission component 130 The base 110 is located on one side of the transmission seat 140 and is provided with a sealing steel sheet 150, and both ends of the base 110 are provided with a pressure plate 111 to fix the sealing steel sheet 150 on the surface of the base 110, and the surface of the base 110 is provided with a positioning groove 112, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com