Deviation rectifying mechanism

A technology of rectifying and stepping motor, applied in the field of rectifying mechanism, can solve the problems of increased labor cost, decreased efficiency, and decreased sewing quality of clothes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

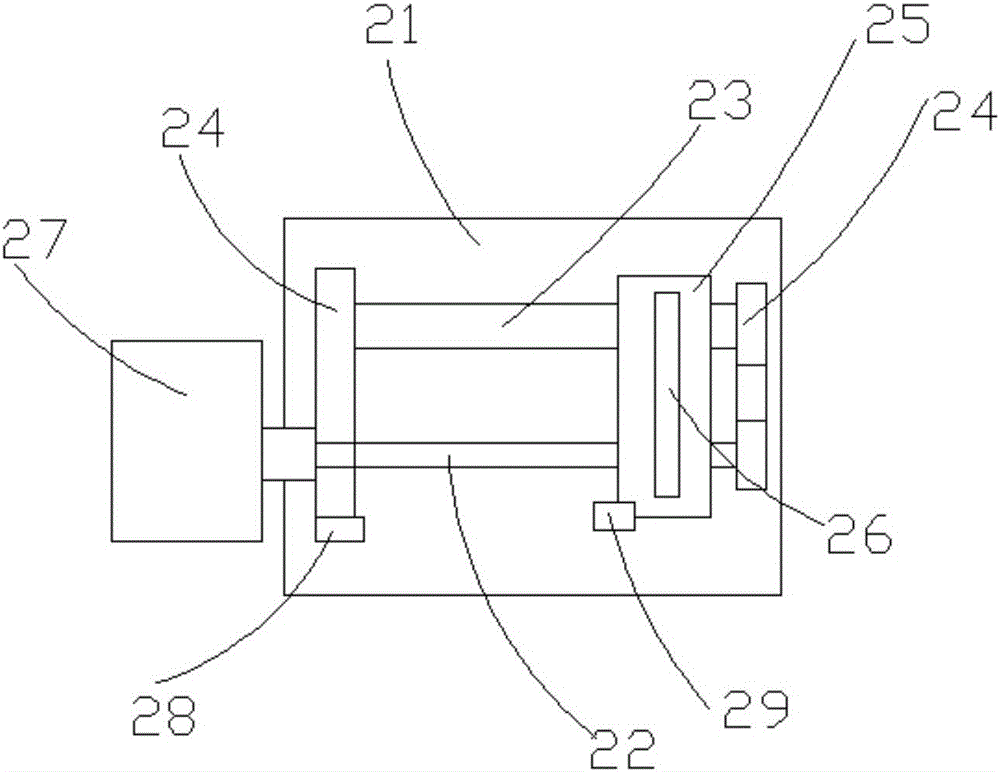

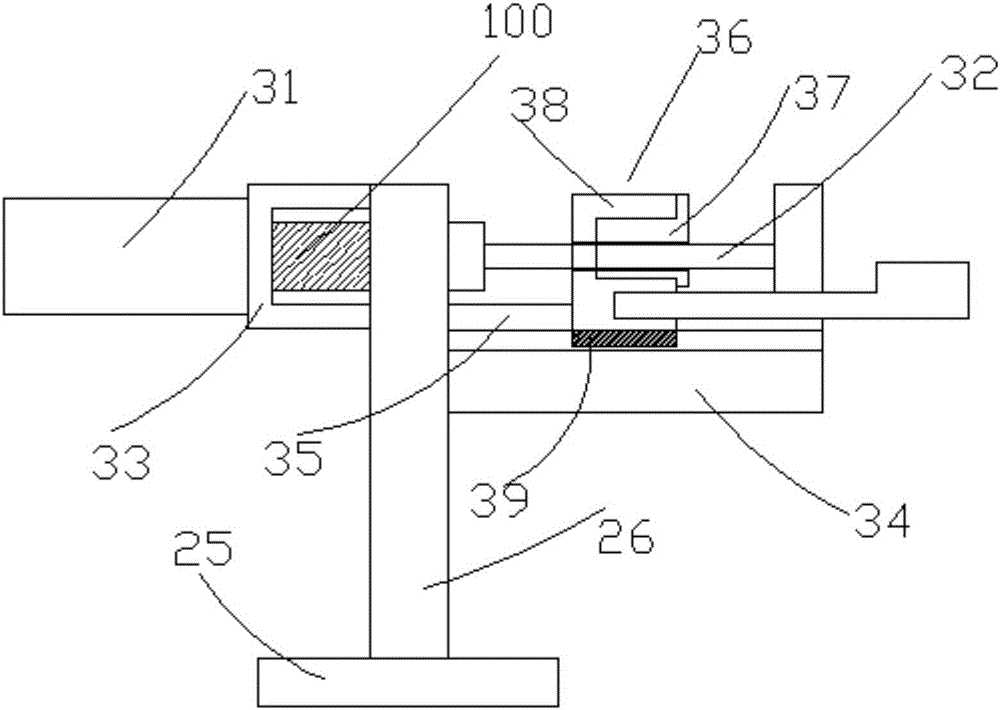

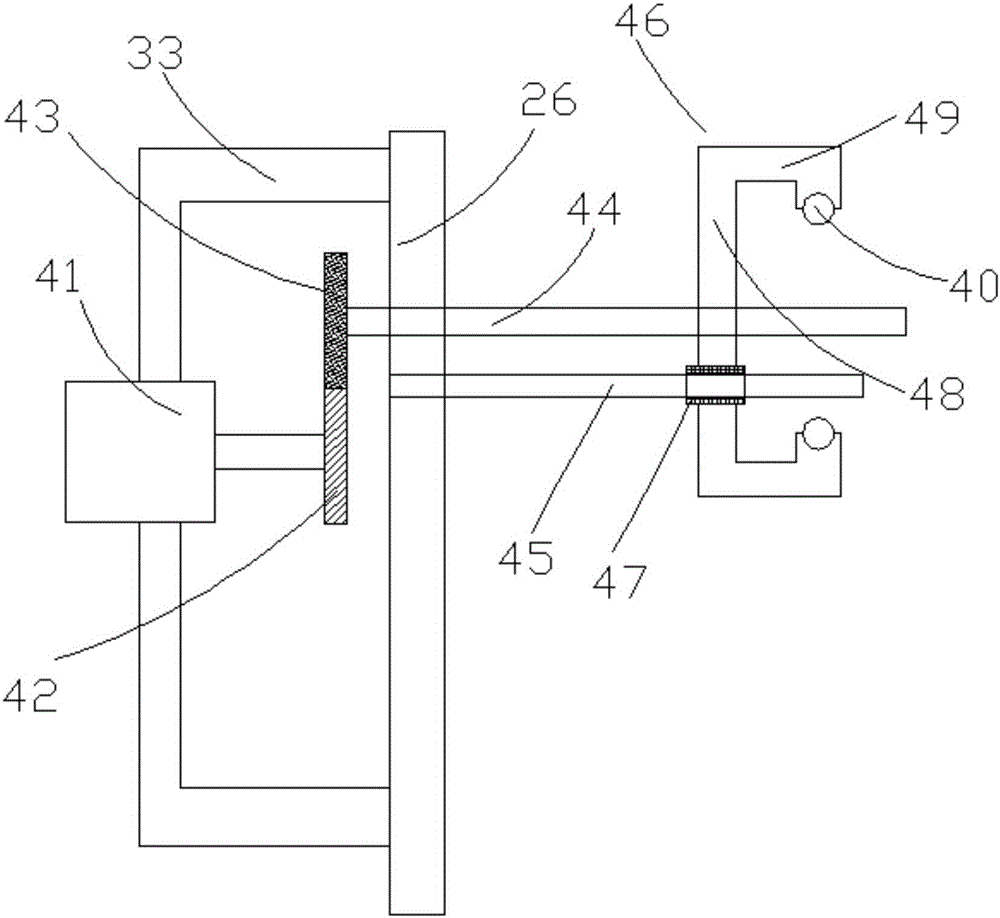

[0033] Such as Figure 1 to Figure 11 As shown, the present invention discloses a deviation correction mechanism, which is characterized in that it includes a linear guide rail assembly, and two deviation correction assemblies arranged symmetrically up and down are arranged on the linear guide rail assembly, and an opening is provided between the two deviation correction assemblies. Assemblies, the end of the deflection correction component is provided with an unwinding component, and also includes a vision detection component and a control chip, and the control chip is connected with the linear guide assembly, the deflection correction component, the opening component, and the vision component. The control chip in the present invention is a conventional technique for those skilled in the art, so it is not repeated here, and the control circuit diagram thereof is as follows Figure 11 shown.

[0034] Such as figure 1 As shown, the linear guide rail assembly in the present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com