Electric cable and its conductor with recognition function, method and forming device for manufacturing the same

A cable conductor and forming device technology, which is applied in the direction of cable/conductor manufacturing, conductors, insulated cables, etc., can solve problems such as tip discharge, increase in conductor manufacturing cost, and decline in electrical and mechanical properties, so as to curb theft and facilitate processing , easy to achieve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

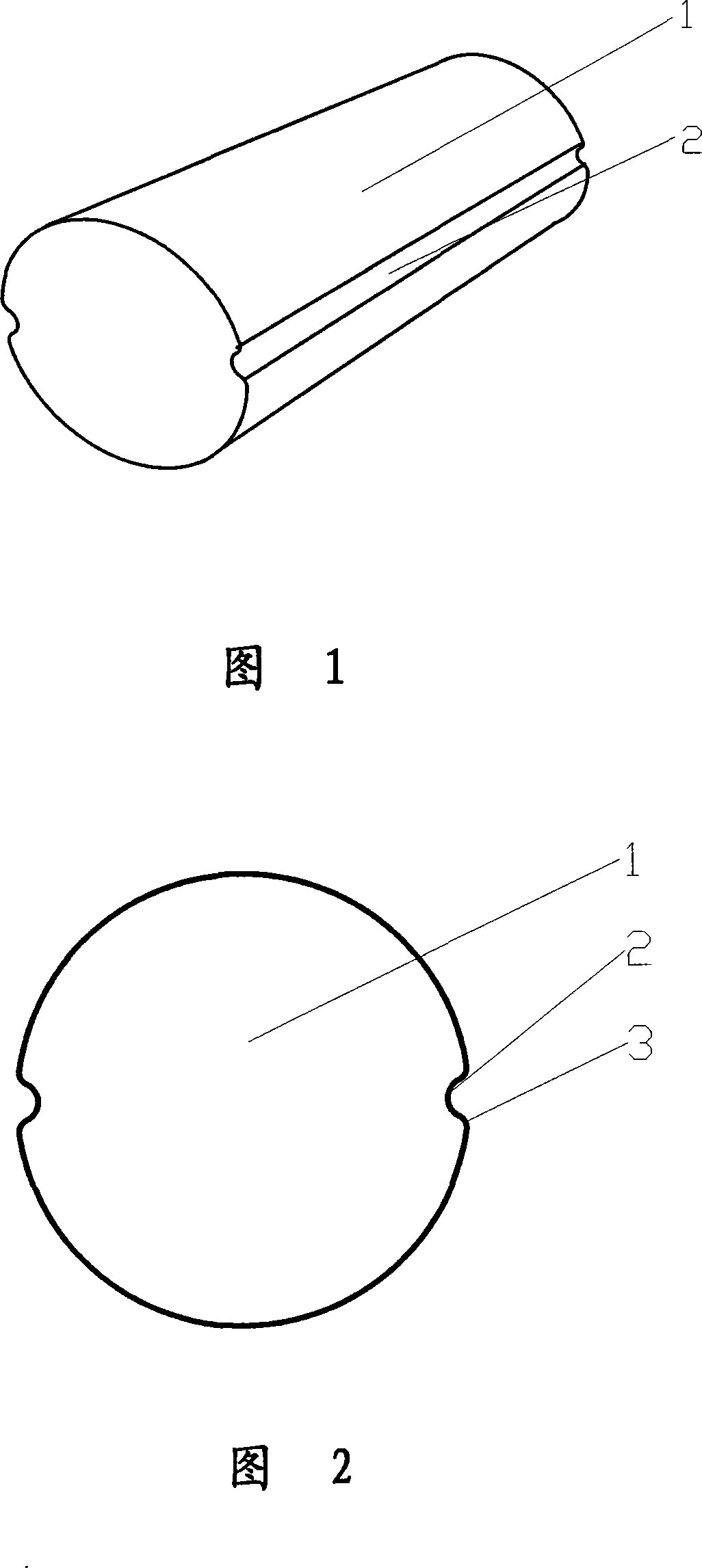

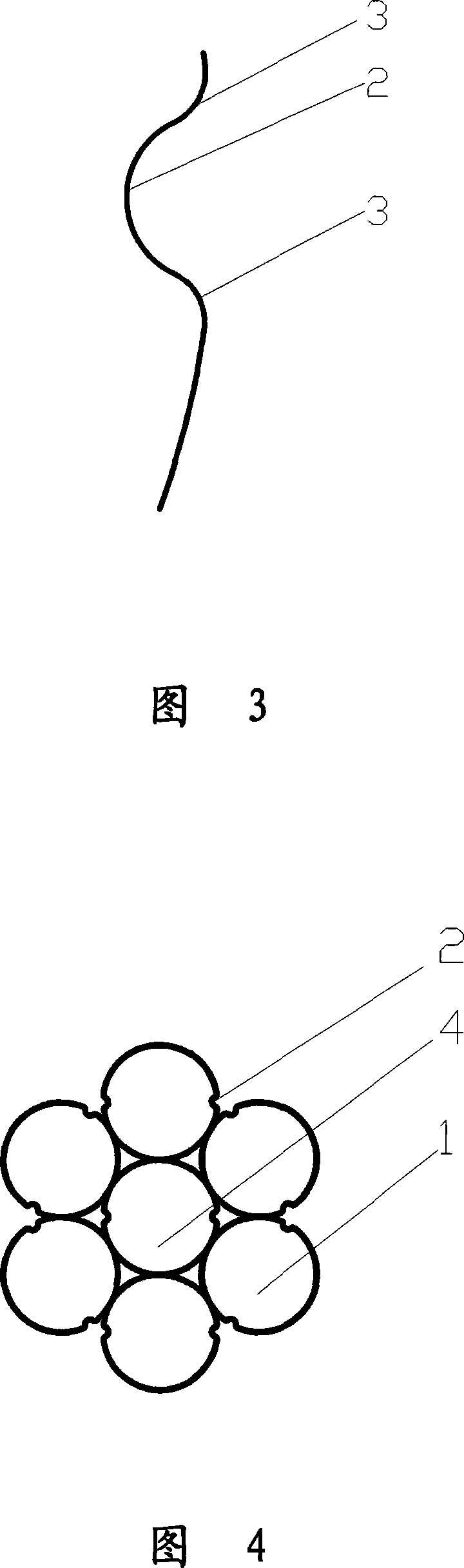

[0037] Embodiment 1: Referring to Figures 1-4, the present invention has a cable conductor with an identification function. There are two arc grooves 2 opposite to each other at 180 degrees on the circumference of the round conductor 1. The width of the upper opening of the groove is 1% of the conductor diameter, and the depth is 1%. It is 0.5% of the diameter of the conductor, and the edge 3 on both sides of the groove meets the surface of the conductor in a smooth arc transition. The circular arc groove on the conductor is processed by rolling and pressing before stranding. The twisted core 4 of the cable is formed by twisting all the aforementioned equal-diameter conductors 1 with identification grooves.

Embodiment 2

[0038] Embodiment 2: Referring to FIG. 5 , as mentioned above, the twisted core 4 of the cable with identification function of the present invention is composed of the above-mentioned relatively thin conductor 1.1 with identification groove 2 and relatively thick conductor 1.2 twisted.

Embodiment 3

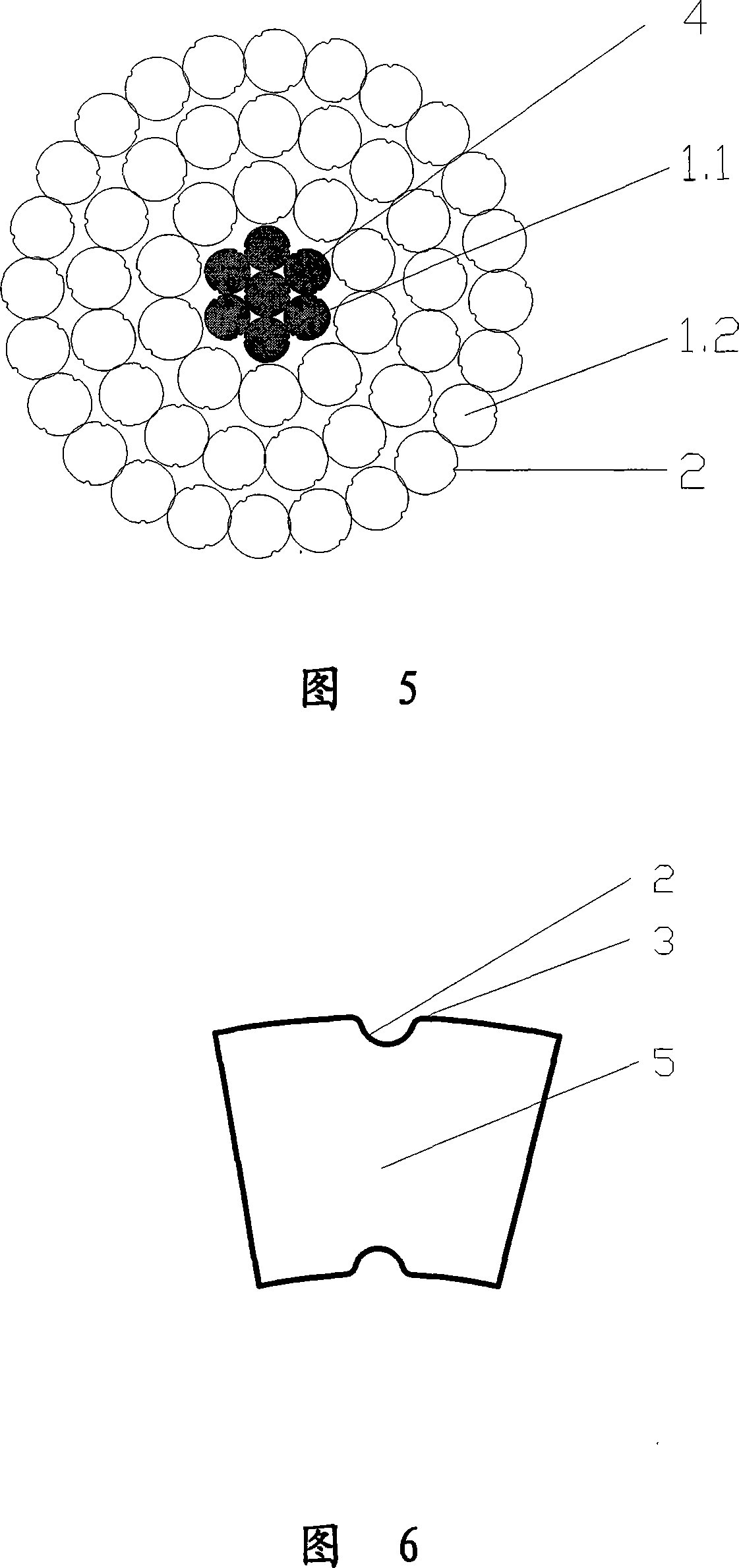

[0039] Embodiment 3: Referring to FIG. 6, as mentioned above, the cable conductor is a bow-shaped conductor 5, and the inner and outer arc surfaces have two arc grooves 2 opposite to each other at 180 degrees, and the edges 3 on both sides of the groove meet the conductor surface in a smooth round shape. The arc is excessive, and the groove on the conductor is rolled and processed before the final forming and winding into a coil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com