Composite multi-stage bag breaking screening machine in friction drive mode

A friction-driven, compound technology, used in sieves, solid separation, unsealing of objects, etc., can solve problems such as increasing equipment maintenance costs, prolonging the process flow, etc., to solve the problems of sieve blockage and tool winding, and reduce maintenance costs. , the effect of enhancing the load-bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

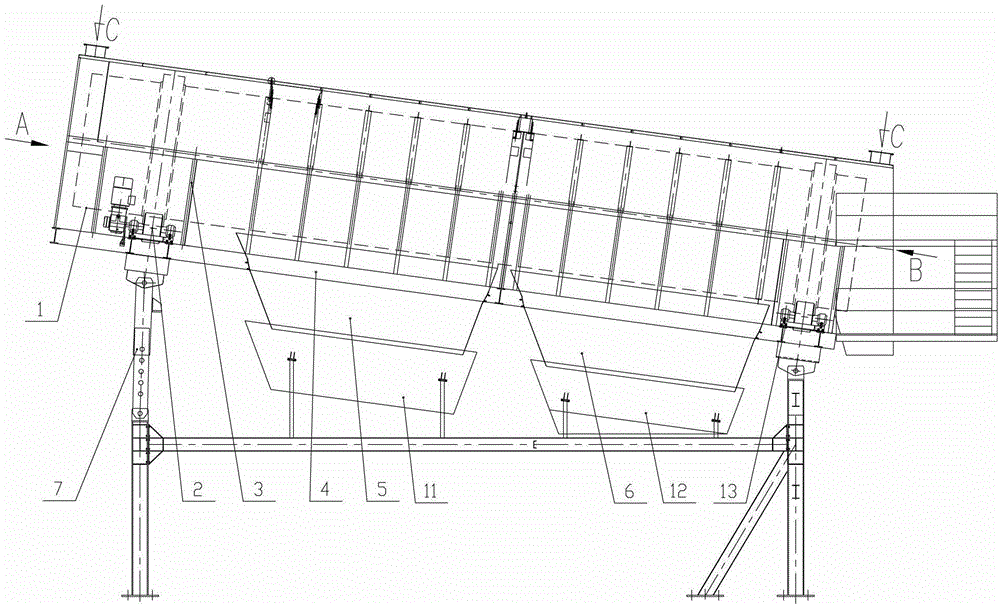

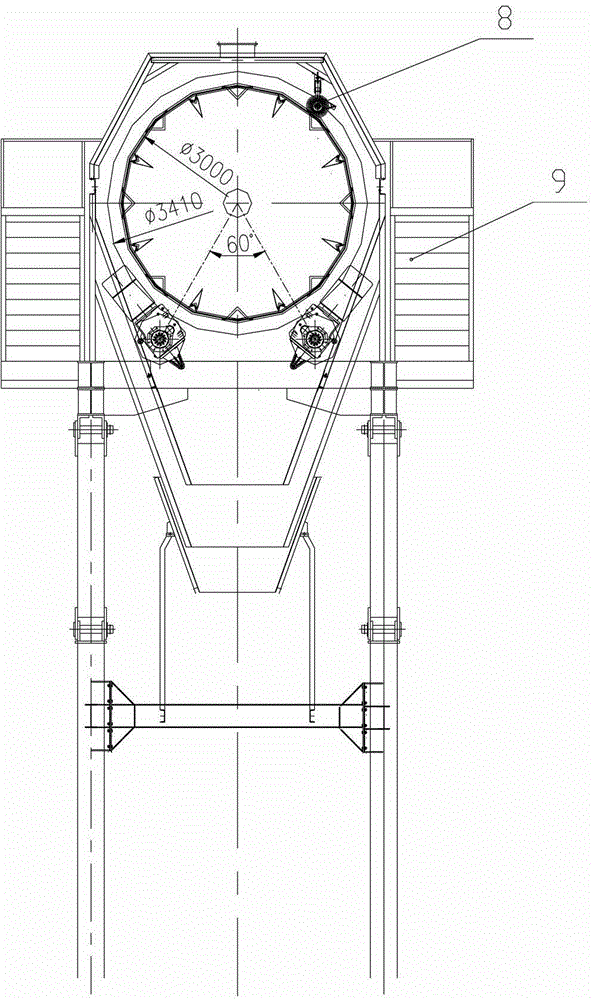

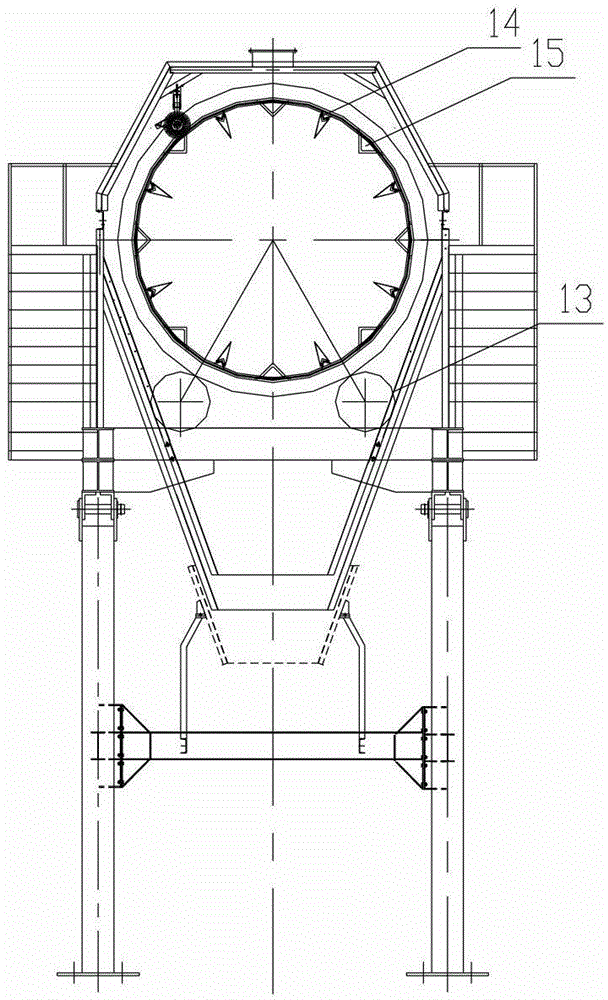

[0028] like Figure 1-Figure 4 As shown, a friction-driven composite multi-stage bag-breaking screening machine includes a screen cylinder 1, a driving device 2, a sealing cover 3, a tray assembly 4, hoppers 5, 6, a steel structure support assembly 7, a cleaner assembly 8, a retaining Wheel assembly 10, fixed hoppers 11, 12, driven device 13.

[0029] The steel structure support assembly 7 is the installation basis of all other functional components, the steel structure is welded, and the steel structure support assembly 7 and the pallet assembly 4 form the installation platform of other functional components, and the height can be adjusted according to needs. The sealing cover 3 is fixed on the height-adjustable steel structure support component 7 through the tray component 4, the steel structure support component is connected with the front and rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com