Parcel Carbel sorting trolley

A cross-belt sorting and trolley technology, which is applied in the direction of transportation and packaging, conveyor objects, conveyors, etc., can solve the problems of complex overall structure, limited processing accuracy, and complicated connection structure of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

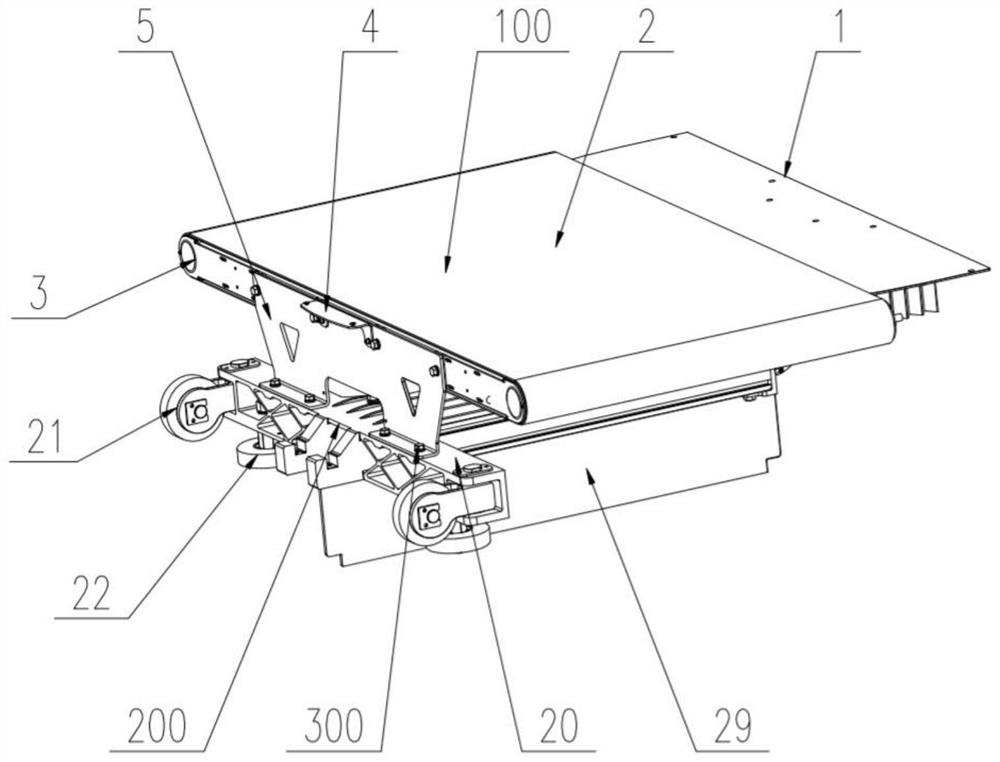

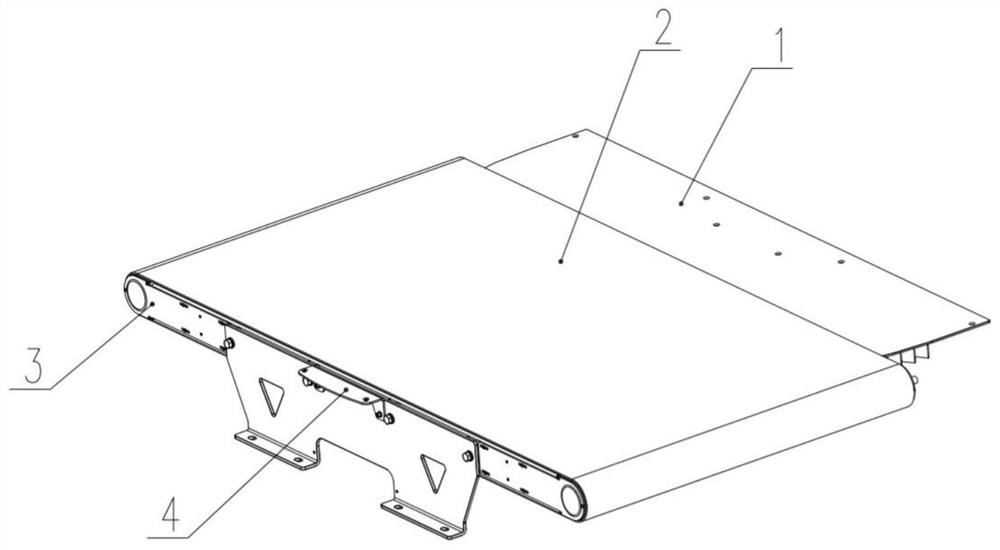

[0051] Example 1, such as Figure 1 to Figure 19 As shown, the parcel cross-belt sorting trolley described in this application is mainly composed of an upper conveying line 100 and a lower frame 200, and an integral car body structure is formed by optimizing the module structure of these two parts and simplifying the interconnection structure.

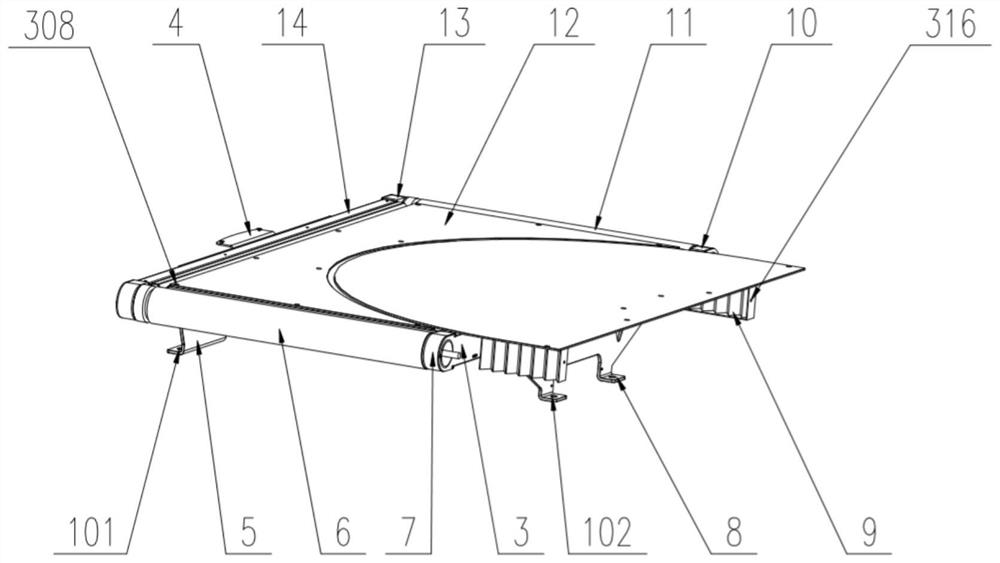

[0052] Such as Figure 2 to Figure 9 As shown, the upper conveying line 100 is composed of the first PA plate 1, the trolley belt 2, the sealing plate 3, the supporting plate 4, the first upper and lower connecting plate 5, the servo electric drum 6, the roller fixing block 7, the second upper and lower Connecting plate 8, organ cover 9, roller fixing block symmetric part 10, unpowered roller 11, second PA plate 12, belt supporting plate 13, and C-shaped plate weldment 14 are composed.

[0053] Specifically, along the direction of conveying goods, two groups of C-shaped plate welding parts 14 are arranged in the front and rear directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com