Ratchet chain type automatic bag breaking equipment

A bag breaking and automatic technology, applied in loading/unloading, packaging, cutting and unsealing, etc., can solve the problems of discontinuous conveying, unsmooth discharge, inconvenient cleaning, etc., achieve simple and convenient recycling, smooth discharge, and avoid jamming Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

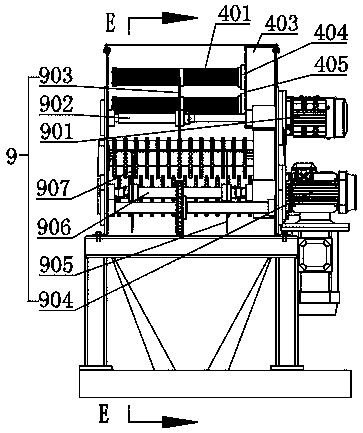

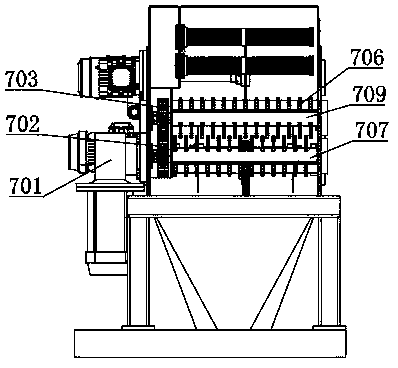

[0058] A ratchet-chain type automatic bag-breaking equipment, comprising a base 1 and a bag-breaking bin 3, the bag-breaking bin 3 including a feed port 2 and a waste bag discharge port 5, characterized in that the inside of the bag-breaking bin 3 is provided with A bag breaking mechanism 9 close to the feed port 2, a waste bag extrusion mechanism 7 close to the waste bag discharge port 5, and a sprocket mechanism 8 running through the feed port 2 and the waste bag discharge port 5;

[0059] The sprocket mechanism 8 is used to receive the material bag input from the feed port 2, and transport the material bag to the waste bag discharge port 5;

[0060] The bag breaking mechanism 9 is used to cut the material bag conveyed by the sprocket mechanism 8, so that the material bag can be discharged;

[0061] The waste bag extruding mechanism 7 is used to sequentially discharge and recycle the empty material bags after unloading.

[0062] Such as figure 1 , figure 2 with Figure ...

Embodiment 2

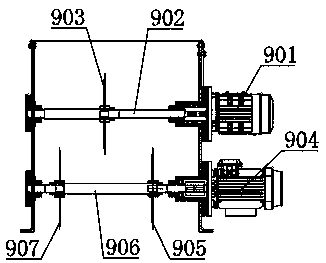

[0087] Such as Figure 18 As shown, the bag-breaking mechanism 9 includes cutting knives arranged in layers up and down, and the cutting knives include three cutting knives located in the upper layer parallel to each other and two cutting knives located in the lower layer parallel to each other. The three cutting knives and the two cutting knives in the lower layer are spaced apart from each other and distributed in a staggered manner.

[0088] Of course, in the above-mentioned embodiment, the cutting knives on the upper layer and the cutting knives on the lower layer are arranged parallel to each other, and the cutting knives on the upper and lower layers are distributed in a staggered manner, so that the material bag can be cut section by section, and the uniform The material bag is cut open, and all the materials can be quickly leaked out to realize fast unloading.

Embodiment 3

[0090] Such as Figure 15 with Figure 17 As shown, the dust removal mechanism 4 is arranged on the side of the broken bag bin 3 and arranged vertically.

[0091] The dust removal filter elements 401 are vertically distributed to absorb dust, and the dust removal chamber 403 is located at the upper end. This structure saves design space, improves space utilization, and ensures dust removal effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com