Movable shaft double-wheel bag breaking machine

A double-wheel, bag-breaking machine technology, which is applied in packaging, cutting and unsealing, transportation and packaging, etc., can solve the problems that the bag-breaking machine cannot break the bag and affect the efficiency of garbage disposal, so that it is not easy to jam the machine and improve the efficiency of bag breaking. Efficiency, the effect of uniform feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

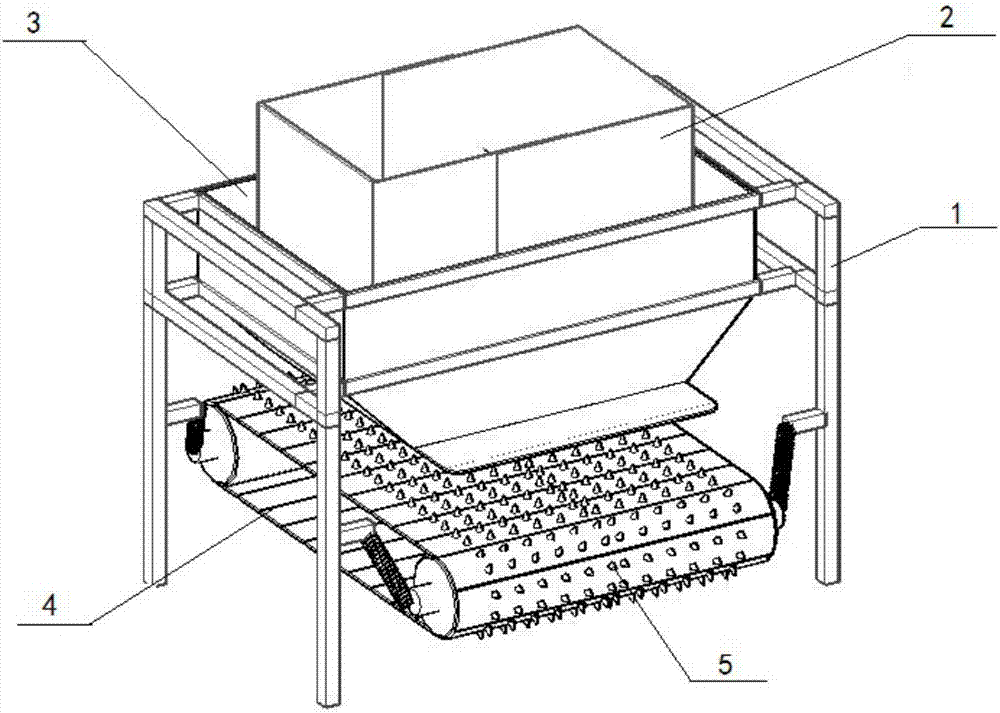

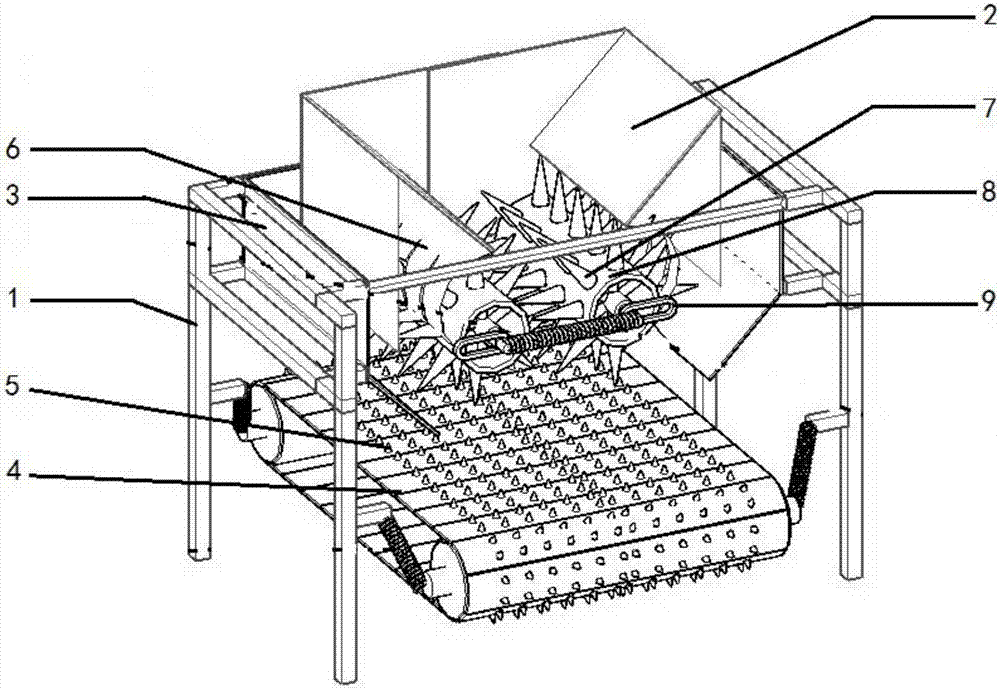

[0019] Such as Figure 1-Figure 3 Shown, the present invention comprises support 1, the box body 3 above support 1, two bag breaking rollers 8, two feeding baffles, chain conveyor 4 and motor, breaking bag roller 8 and feeding baffle are positioned at box Inside the body 3, the chain conveyor 4 is located below the box body 3, and the bag breaking roller 8 is arranged between two feed baffles; the outer periphery of the bag breaking roller 8 is provided with a bag breaking cone 7, and the chain conveyor 4 The surface of the conveyor belt is provided with a short bag-breaking cone 5; the motor drives two bag-breaking rollers 8 to rotate in opposite directions and the delivery wheel of the chain conveyor 4 to rotate. The setting of the feeding baffle makes the material broken by the bag-breaking roller 8 fall onto the chain conveyor 4 below.

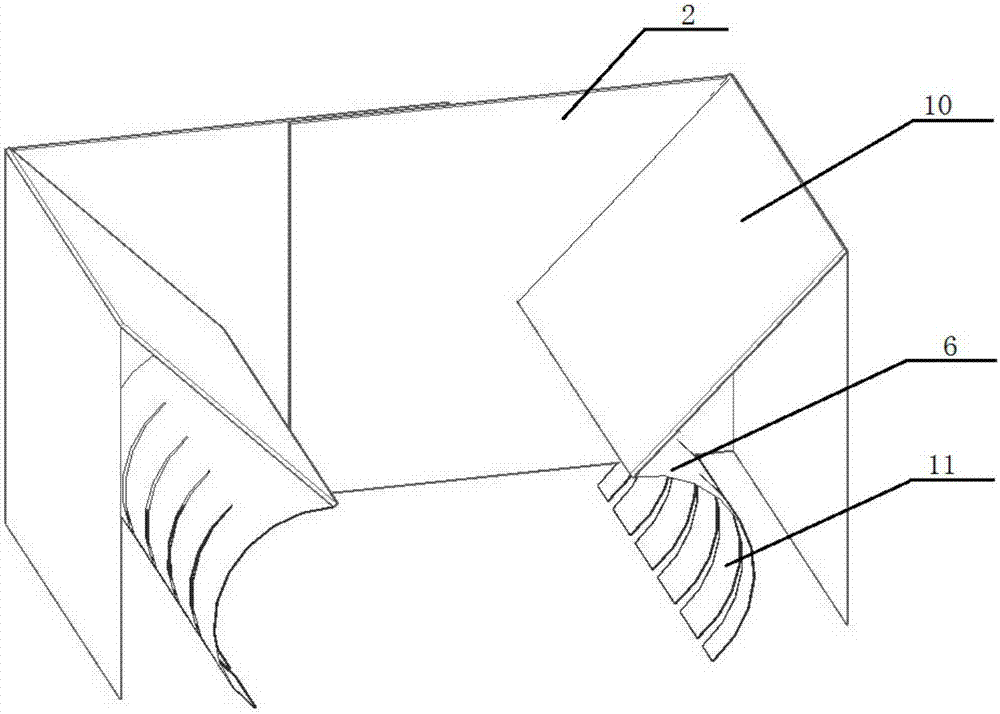

[0020] Such as figure 2 As shown, the feeding baffle is composed of a scraper 6 and a baffle 2, and the rotating shaft of the bag-brea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com