Method for recovering carbon dioxide by multistage liquefaction and staged refrigeration of industrial tail gas

A technology for industrial tail gas and carbon dioxide, applied in separation methods, chemical instruments and methods, chemical industry, etc., can solve the problems of low carbon dioxide yield and high energy consumption of devices, so as to improve refrigeration efficiency, reduce system energy consumption, and improve thermal cycle Effect of Efficiency and Cooling Coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

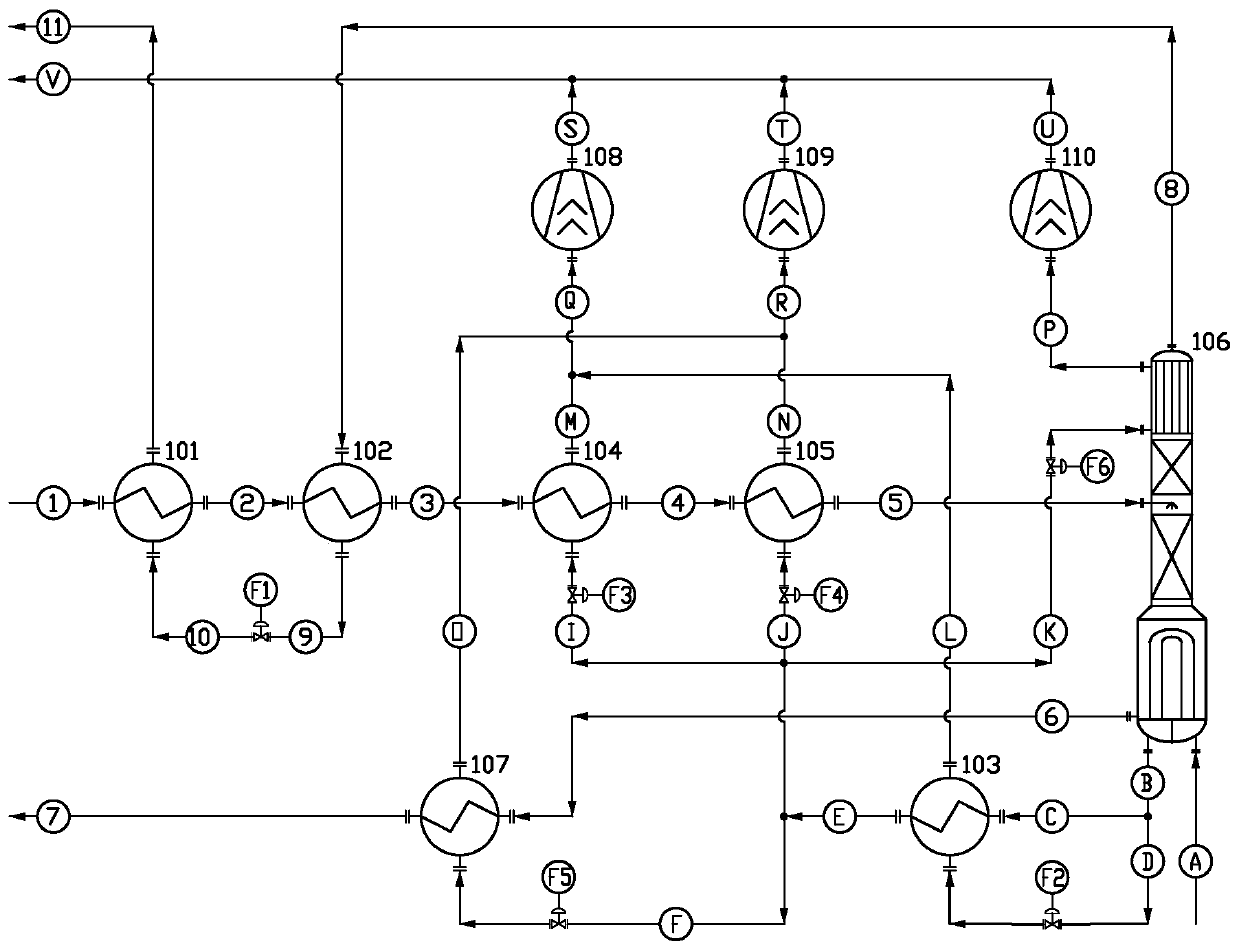

[0044] like figure 1 As shown, it is a method for recovering carbon dioxide by multi-stage liquefaction of industrial tail gas and graded refrigeration of the present invention, including a first residual cold recovery device 101, a second residual cold recovery device 102, a primary condenser 104, a secondary condenser 105, a finishing Distillation tower 106, subcooler 107; feed gas pipeline 1, feed gas pipeline 2, feed gas pipeline 3; feed gas gas-liquid mixing pipeline 4, feed gas gas-liquid mixing pipeline 5; product pipeline 6, product pipeline 7.

[0045] The specific steps are as follows: after drying and dehydration, the 3.3MPa, 38°C raw material gas passes through the raw gas pipeline 1 and first enters the first residual cold recovery device 101, and is pre-cooled to 22°C by exchanging heat with the non-condensable gas, and then passes through the raw gas pipeline 2 Go to the second waste cold recoverer 102, and exchange heat with non-condensable gas to be pre-cooled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com