Full-automatic bag cutting machine

A fully automatic, charter technology, used in packaging, cutting and unsealing, transportation and packaging, etc., can solve the problems of inability to dump clean materials, high stacking type requirements, low work efficiency, etc., achieve low flatness requirements, high degree of automation, The effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

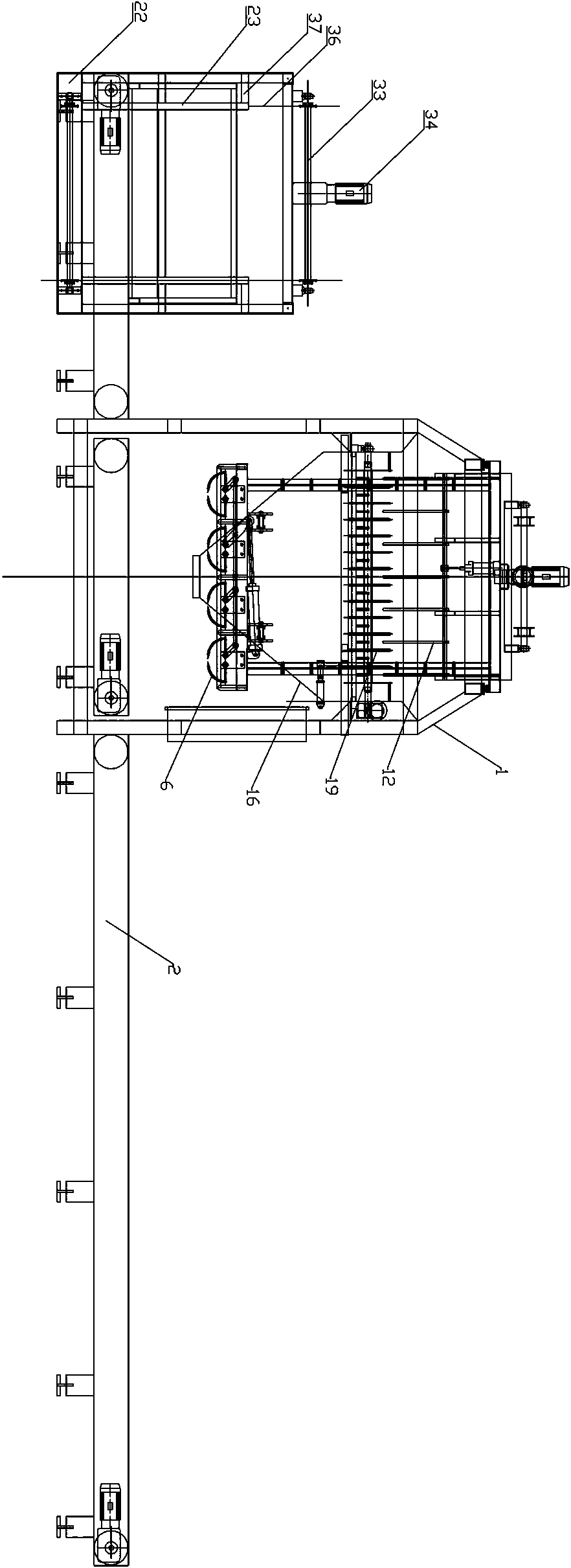

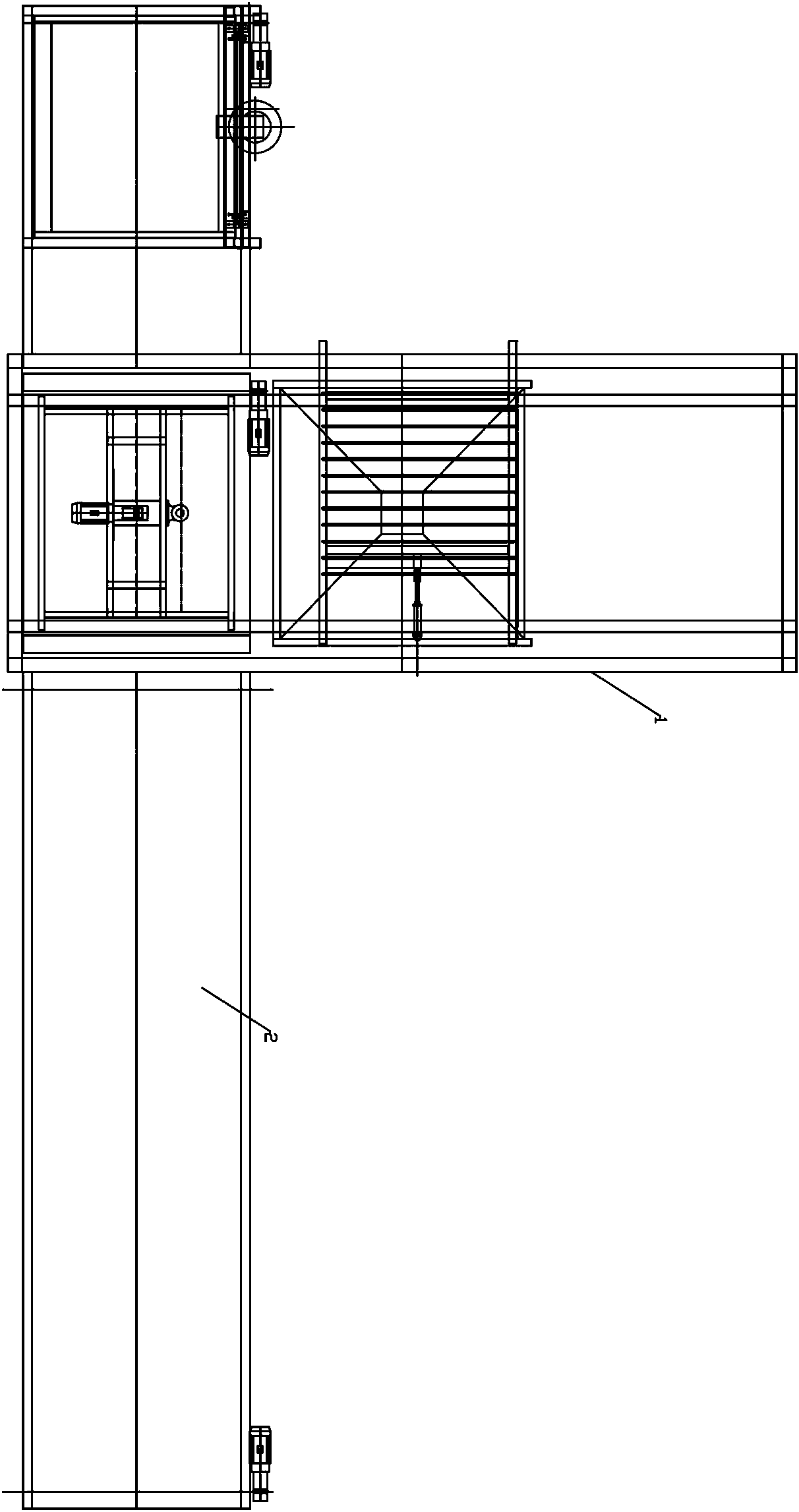

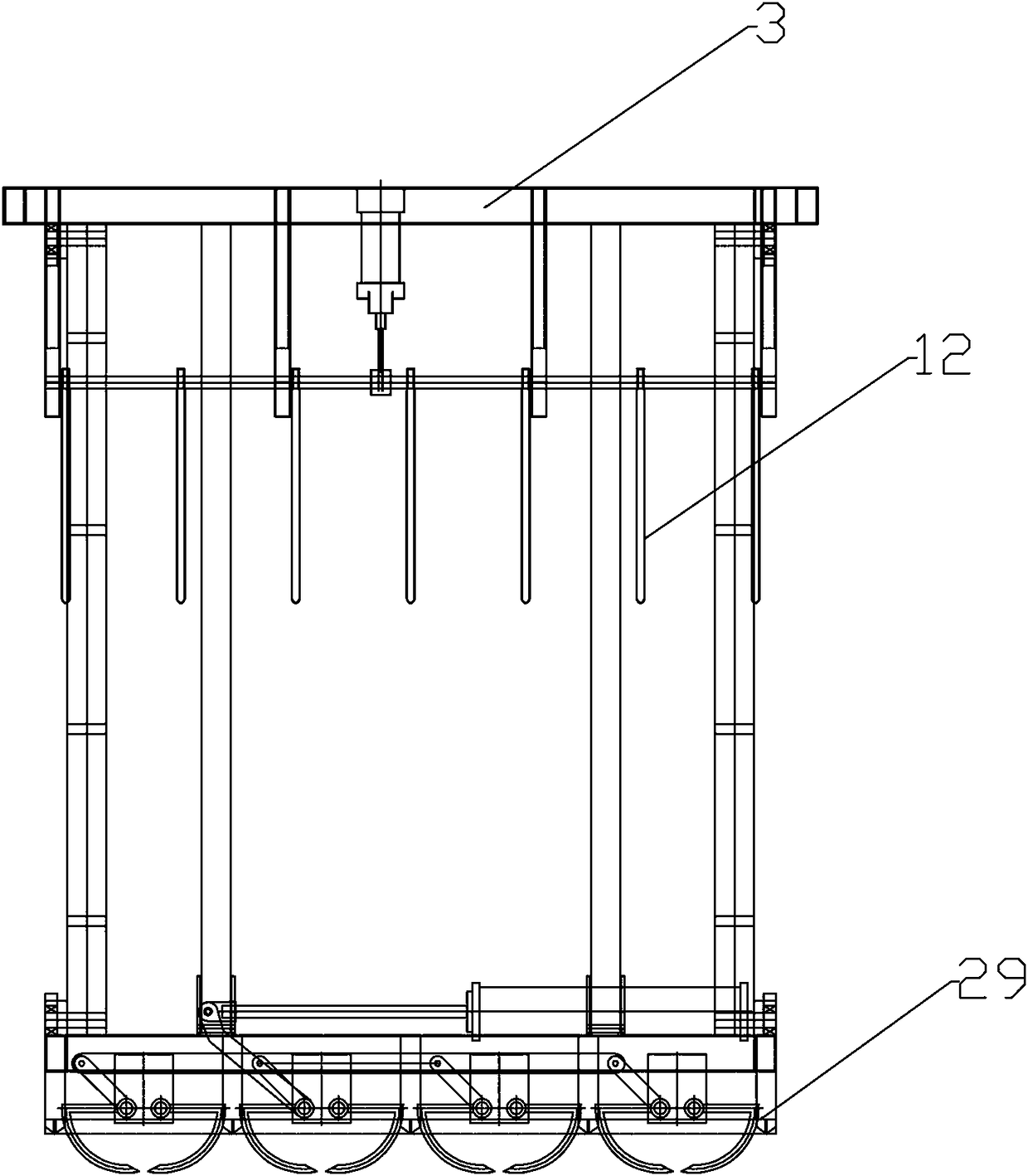

[0040] Embodiment 1: a kind of automatic bale cutting machine, as Figure 1-19 Shown, comprise frame 1 and be arranged on the conveying device on the frame, catch bag device, cut bag device and empty pallet stacking device, conveying device comprises conveyer belt 2 and the pallet placed on conveyer belt, as figure 1 , figure 2 As shown, the conveyor belt is transported from right to left, and the material bags are stacked on the pallet, and the pallet is conveyed forward (left) intermittently with the conveyor belt 2. The bag grabbing device and the bag cutting device are located in the middle of the conveyor belt 2. The bag grabbing device can Pick up the material bag on the tray and move it to the top of the bag cutting device. Under the action of the cutting knife of the bag cutting device, the material bag is cut, and the material in the material bag is shaken off and collected. When the material on the tray After all the bags are unpacked, the conveyor belt 2 is transp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com