Garbage bag breaking machine

A bag-breaking machine and bag-breaking technology, which is applied in packaging, grain processing, transportation and packaging, etc., can solve the problems affecting the garbage processing process, the whole line cannot run, hang materials, etc., and achieve high bag-breaking efficiency and good effect , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

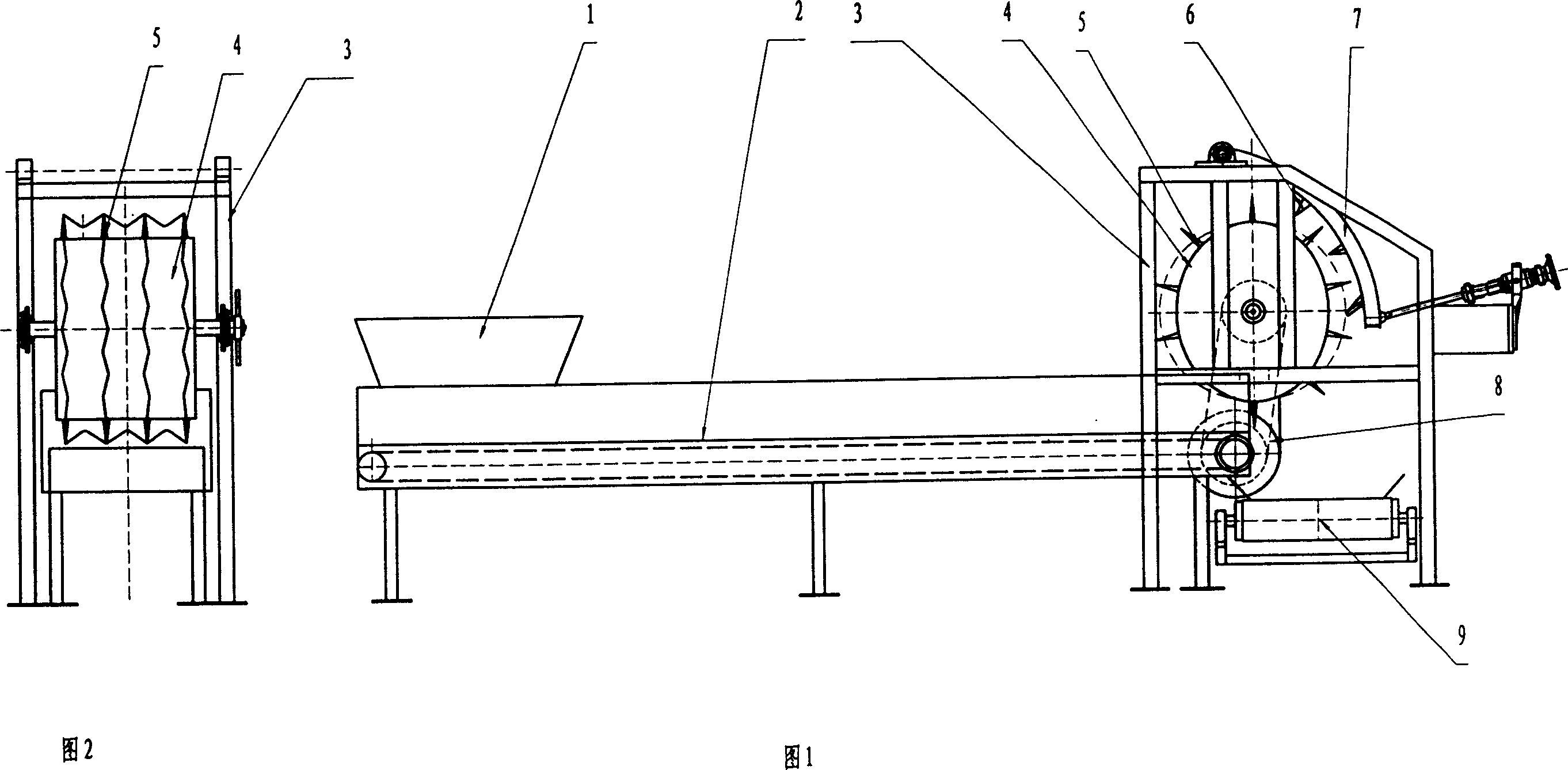

[0027] Refer to Figure 1 and Figure 2.

[0028] The garbage bag breaking machine includes a material conveyor 2, a fixed bracket 3, a bag breaking mechanism, and a power mechanism 8. The material conveyor is installed in conjunction with the bag breaking mechanism. The material conveyor 2 is equipped with a material inlet 1. The fixed bracket 3 is equipped with a bag breaking mechanism, and the bag breaking mechanism is driven by a power mechanism. The bag breaking mechanism is composed of a material shifting knife 5 and a fixed knife 6 fixed on the rotating hub. The power mechanism 8 drives the material shifting knife 5 on the rotating hub material shifting mechanism 4, and the material shifting knife 5 and the fixed knife 6 rotate relative to each other. . The bag-breaking fixed knife 6 is fixed on an adjusting frame that can adjust the distance between the fixed knife and the material shifting rotary knife. The adjusting frame is a screw spring structure. One end of the screw i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com