Cloth strip slitting device capable of performing respective rolling for curtain processing

A cloth and curtain technology, which is applied in the field of fabric stripping devices, can solve the problems of incomplete fabric stripping, fabric cutting jams, and intermittent stripping, so as to improve stripping efficiency, avoid wrinkles, and prevent stripping interruptions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

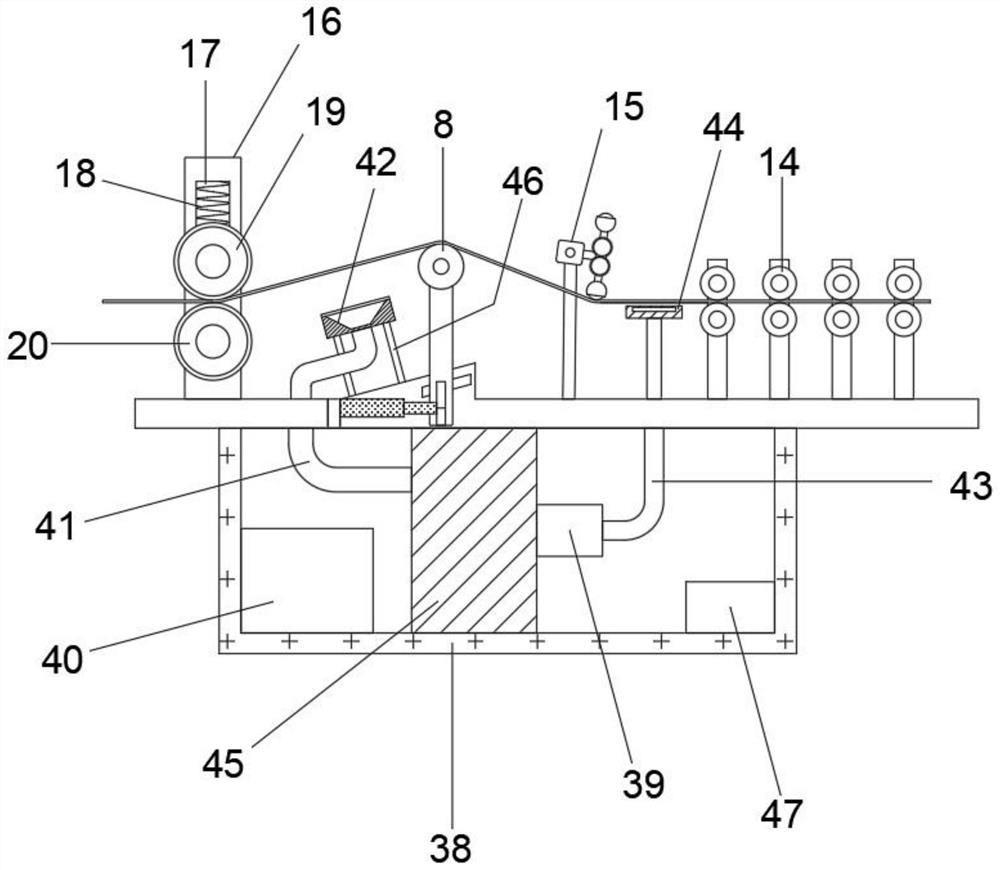

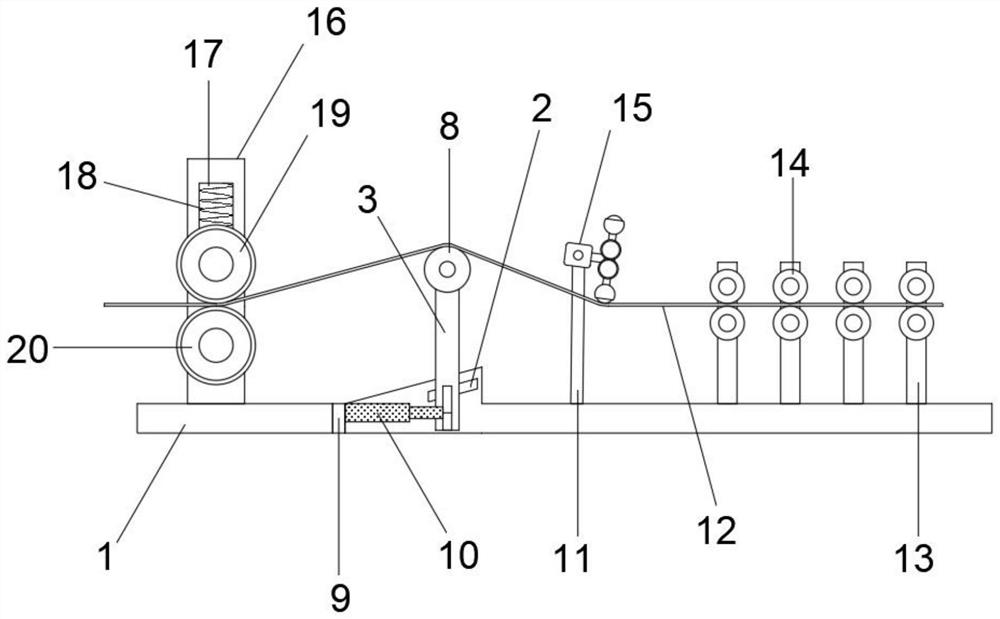

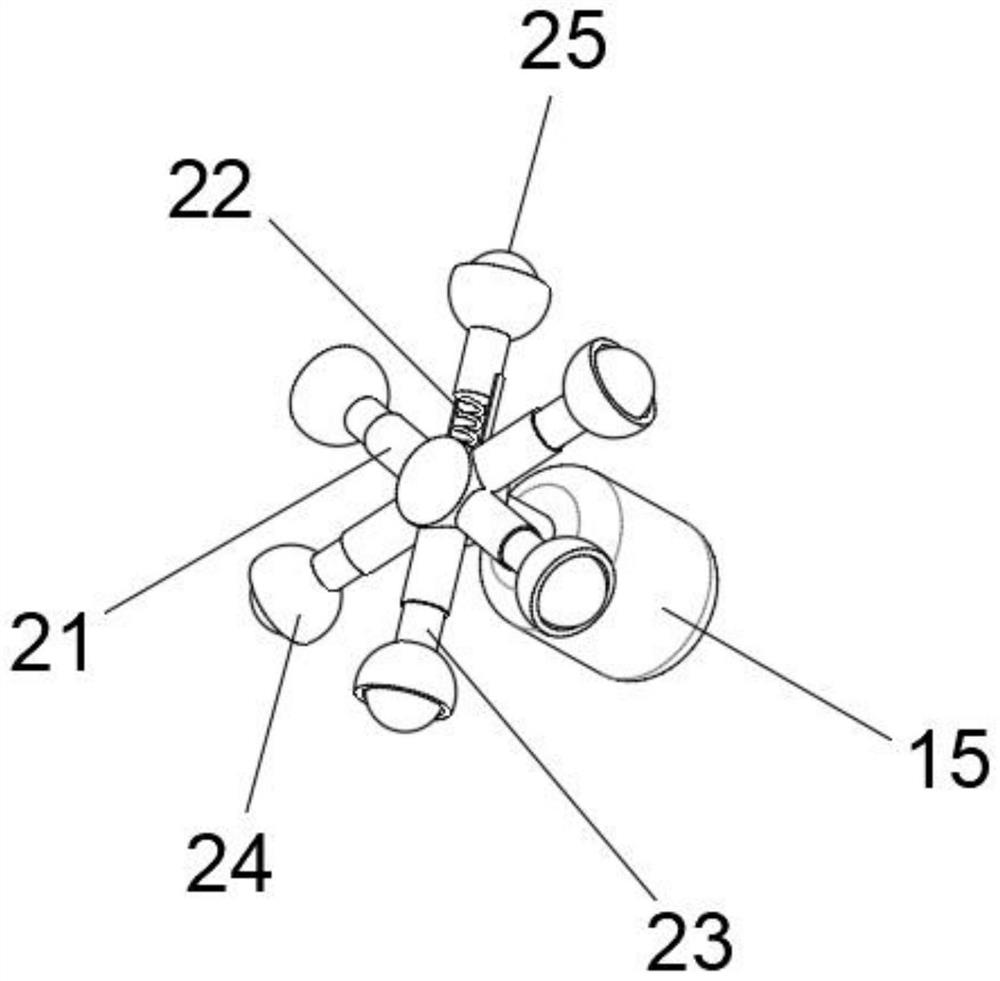

[0038] see Figure 1-8 , the present invention provides a technical scheme of a cloth stripping device for separately winding curtain processing: it includes a base plate 1 and a cloth 12, the top outer wall of the base plate 1 is provided with a driving winding mechanism, and one side of the outer wall of the base plate 1 is provided with a slope Slot 2, the inner wall of the chute 2 is plugged with a slider 4, and the outer wall of one side of the slider 4 is fixed with a knife rest 3, and the outer wall of one side of the knife rest 3 is provided with a chute 28, and the inner wall of the chute 28 is plugged. There is a fixed block 29, one side outer wall of the fixed block 29 is connected with a knife roller 7 through a bearing, the outer wall of the knife roller 7 is connected with a blade 8 through a key, the bottom of the knife rest 3 is provided with a cutting auxiliary assembly, and the top outer wall of the bottom plate 1 is provided with a Paving mechanism, and the ...

Embodiment 2

[0048] Please refer to 9-11, the outer wall of the conveying roller 20 is bonded with uniformly distributed convex lines 32, and the outer wall of the conveying roller 20 is bonded with uniformly distributed convex balls 33, and the uniformly distributed convex lines 32 and convex balls 33 can be larger than The friction force when the cloth 12 contacts makes the conveying process of the cloth 12 more stable and reliable.

[0049] see Figure 9-10 , the outer walls of both sides of the conveying roller 20 are provided with empty grooves 36, the inner walls of the empty grooves 36 are fixed with thin springs 37, and one end of the thin springs 37 is fixed with a ferrule 34, and the ferrules 34 are sleeved on the inner walls of the empty grooves 36, and the sleeves The outer wall of the ring 34 is fixed with a baffle 35, and the thin spring 37 can keep the position of the baffle 35 arranged on the outer wall of the ring 34 relatively fixed. The baffle 35 has a certain height to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com