Garbage bag-breaking machine

A bag breaking machine and bag breaking technology, which is applied in packaging, cutting and unsealing, transportation and packaging, etc., can solve the problems of large garbage bags, jamming of shredders, broken bags of garbage bags, etc., and achieve scientific and reasonable design and good performance Good, high bag breaking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

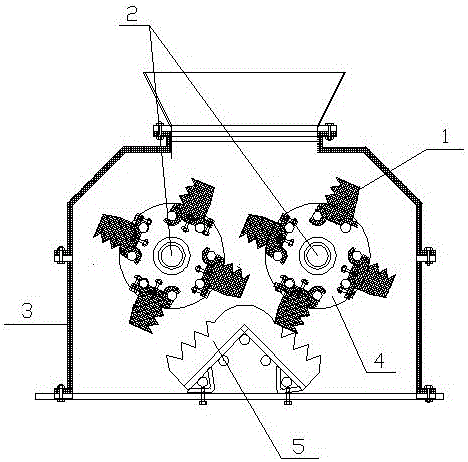

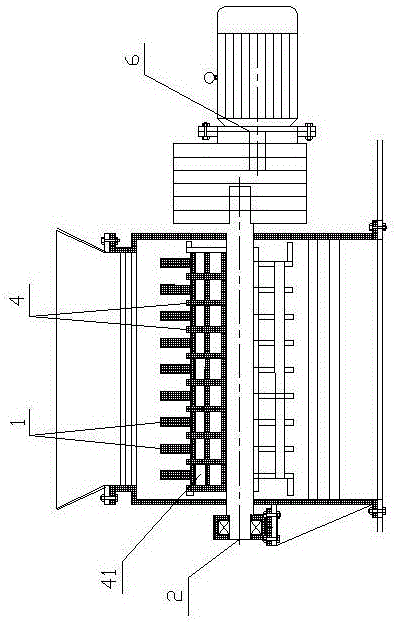

[0024] Example: garbage bag breaking machine, such as Figures 1~5 As shown, it includes a bag breaking knife 1 , a main shaft 2 , a body frame 3 and a driving mechanism 6 . The main shaft 2 is arranged in the body frame 3 , there are a plurality of bag breaking knives 1 , and the plurality of bag breaking knives 1 are arranged on the main shaft 2 , and the rotation of the main shaft 2 is driven by the driving mechanism 6 .

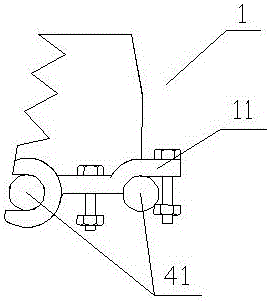

[0025] The front side edge of the bag-breaking knife 1 is serrated, and the bottom of the bag-breaking knife 1 is provided with a buckle part 11 (for the more specific shape and detailed structural features of the bag-breaking knife 1, see another article entitled "A garbage bag-breaking knife". patent application). A plurality of circular fixing discs 4 are evenly arranged on the main shaft 2 , and a plurality of blade fixing shafts 41 are fixed in parallel around the main shaft 2 through the circular fixing discs 4 . The blade fixing shaft 41 traverse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com