Swing type broken bag sorting machine with spraying structure

A swing type, sorting machine technology, applied in the direction of solid separation, cleaning method using liquid, filter and sieve, etc., can solve the loss of nutritional materials, timely recovery of unfavorable useful materials, high production efficiency of the overall process, no bag breaking function, etc. problems, to achieve the effect of stable mechanical rotation, reduced convenience, and novel overall structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

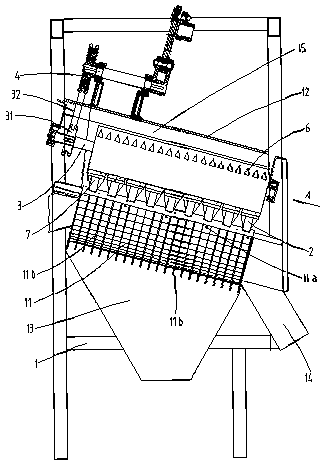

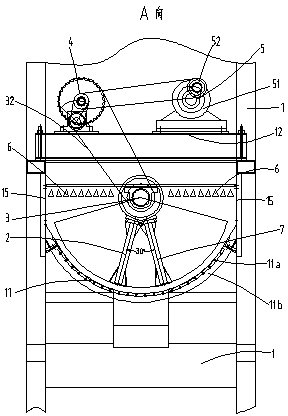

[0019] Such as Figure 1 to Figure 2 As shown, the icon numbers are explained as follows: frame body 1, filter screen plate 11, unit filter mesh hole 11a, rib plate 11b, upper sealing plate 12, lower connecting hopper 13, rear connecting hopper 14, left and right warehouse plates 15, unit Swing block 2, main shaft 3, driving wheel 31, chain 32, balance wheel assembly 4, driving motor 5, rotating disk 51, driving rod 52, spraying assembly 6, movable shear block 7.

[0020] In the embodiment of the present invention, the swing-type bag-breaking sorter with a spray structure includes a frame body 1, a unit swing block 2, a main shaft 3, a balance wheel assembly 4, and a driving motor 5; The filter screen plate 11 arranged obliquely from front to back is equipped with an upper sealing plate 12 above the frame body 1, and the upper sealing plate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com