Garbage bag breaking device

A technology for breaking bags and garbage, which is applied in packaging, transportation and packaging, and unsealing of objects, etc. It can solve the problems of complex structure of garbage bag breaking device, low bag breaking efficiency of bag breaking knife, easy blocking and hanging of materials, etc., to achieve The bag breaking operation is stable, the bag breaking efficiency is high, and it is not easy to block and hang materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

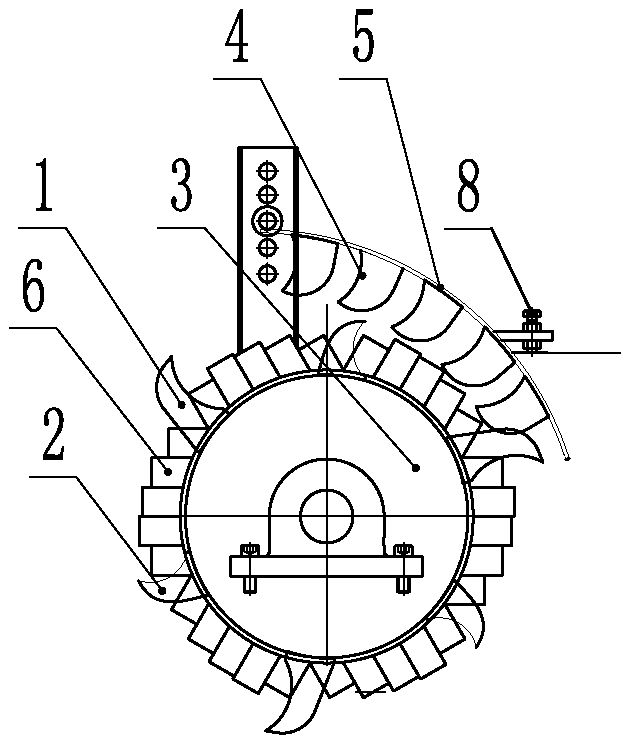

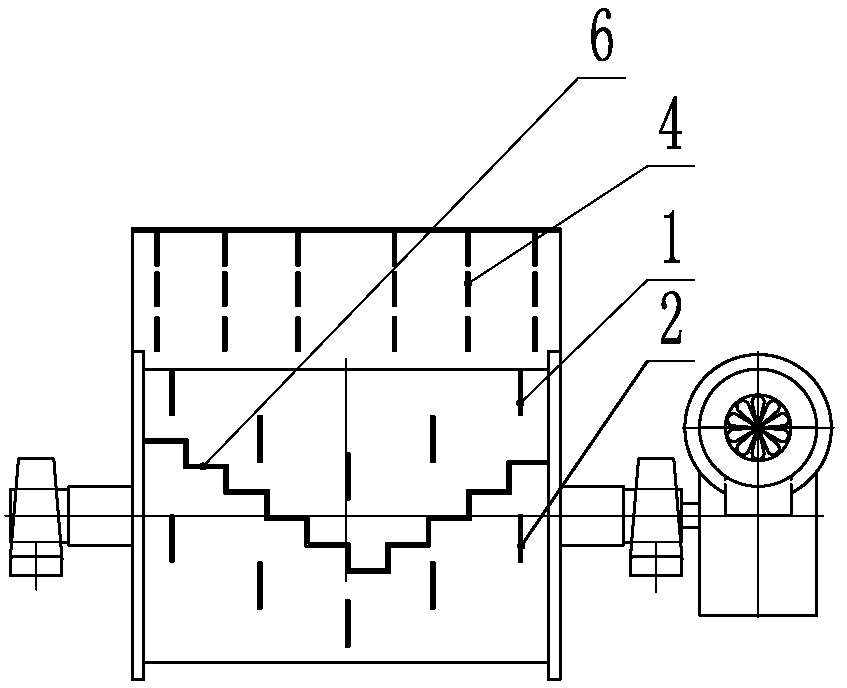

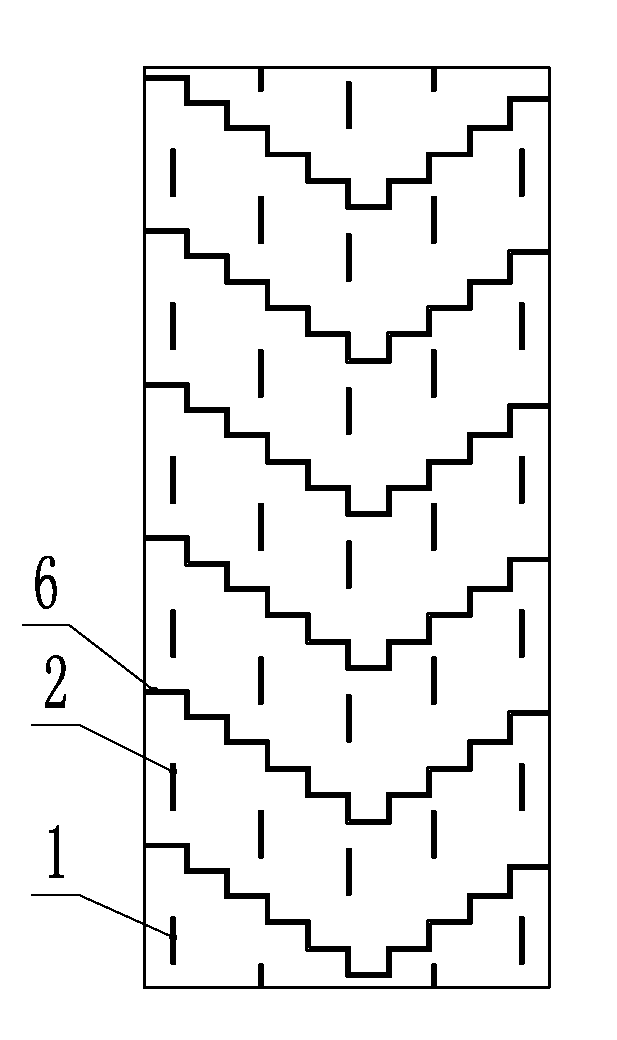

[0013] Description with reference to the accompanying drawings. Among the figure, the wheel hub 3 is supported by the bearing seat, and the power motor drives the wheel hub 3 to rotate through the reducer, and the bearing seat and the reducer are installed on the rubbish bag breaking device frame body. The rear end of the cover plate 5 is hinged on the garbage bag breaking device frame body, and five holes are arranged up and down on the garbage bag breaking device frame body. height adjustment. The cover plate 5 covers the top of the hub 3 , and the inner arc surface is opposite to the peripheral surface of the hub 3 . Three long moving knives 1 and three short moving knives 2 form a row of long and short moving knives. Perpendicular to the axis of the hub, the long moving knives 1 and short moving knives 2 on each row are arranged evenly and alternately, and the lines connecting the long moving knives 1 and short moving knives 2 on the adjacent long moving knives and short...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com