Formed fuel mixed with combustible garbage components and coal liquefaction residual and preparation method

A technology of coal liquefaction residue and molding fuel, which is applied in the direction of fuel, solid fuel, biofuel, etc., can solve problems such as waste of heat energy, achieve the effects of reducing air pollution, easy storage, and promoting molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

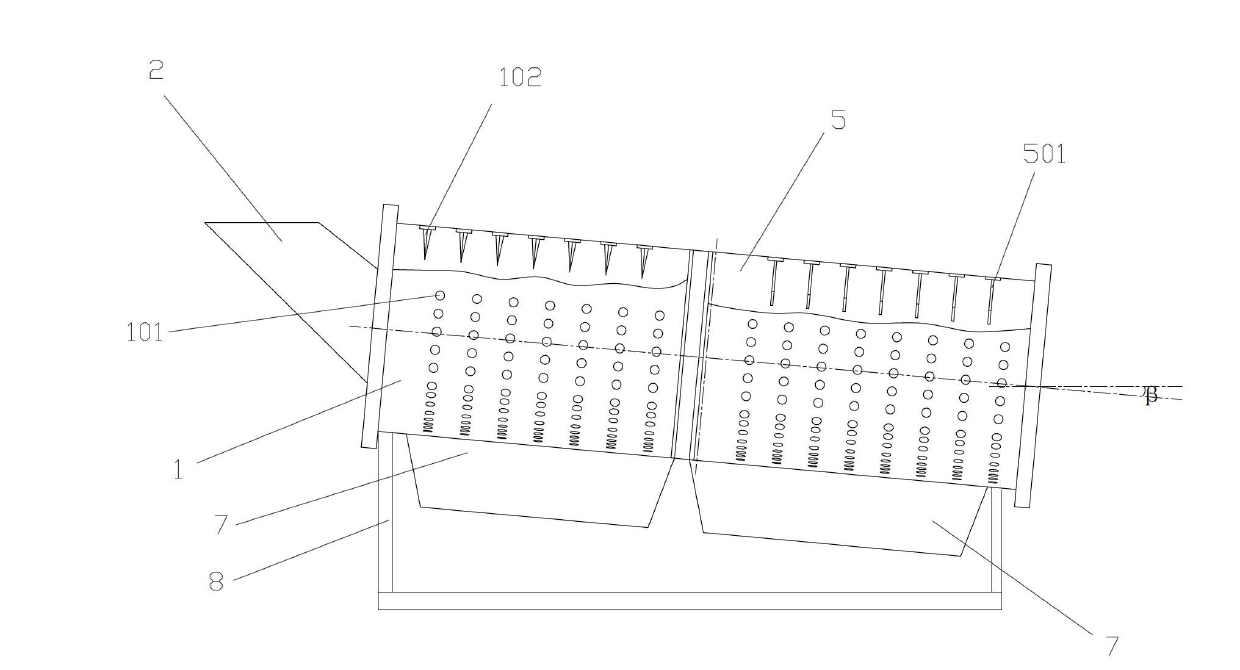

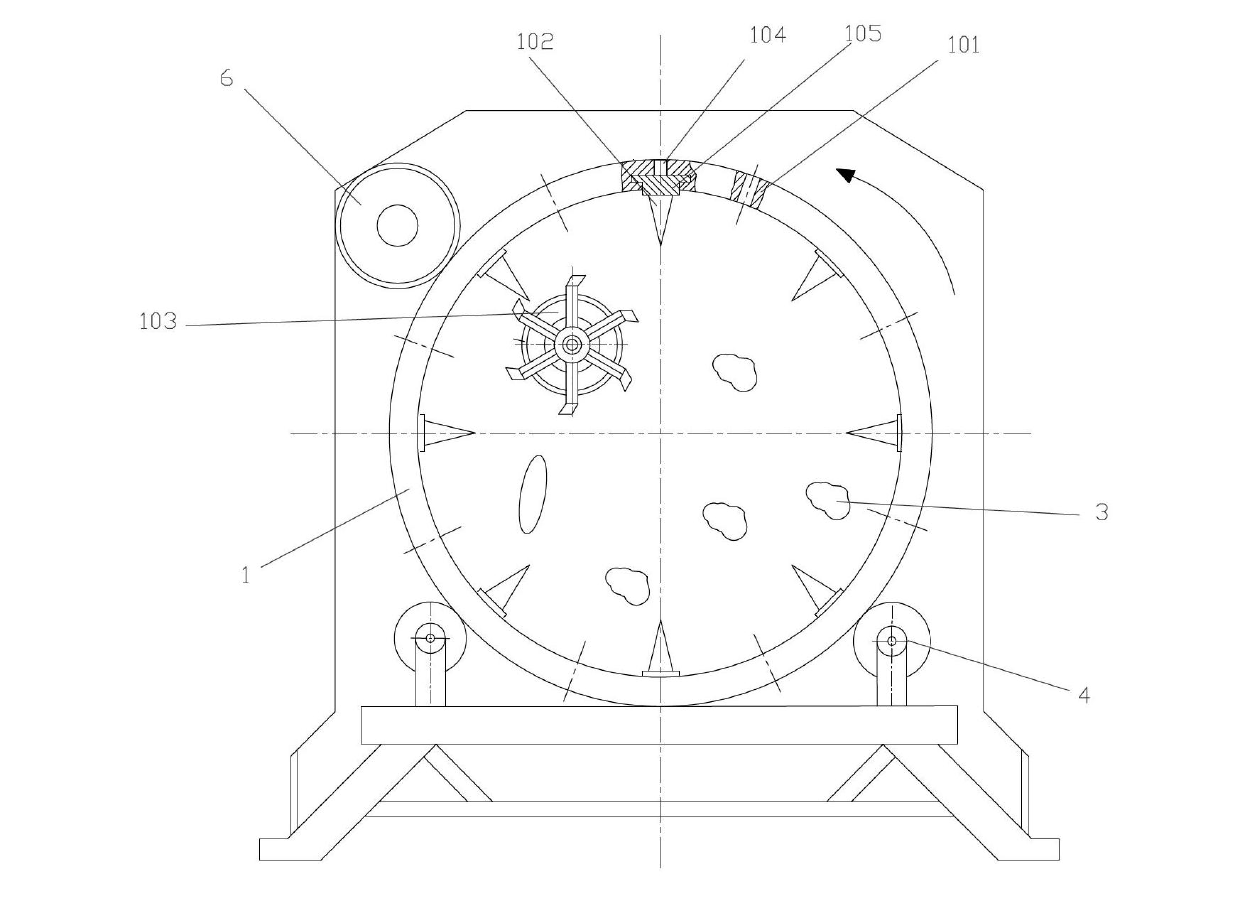

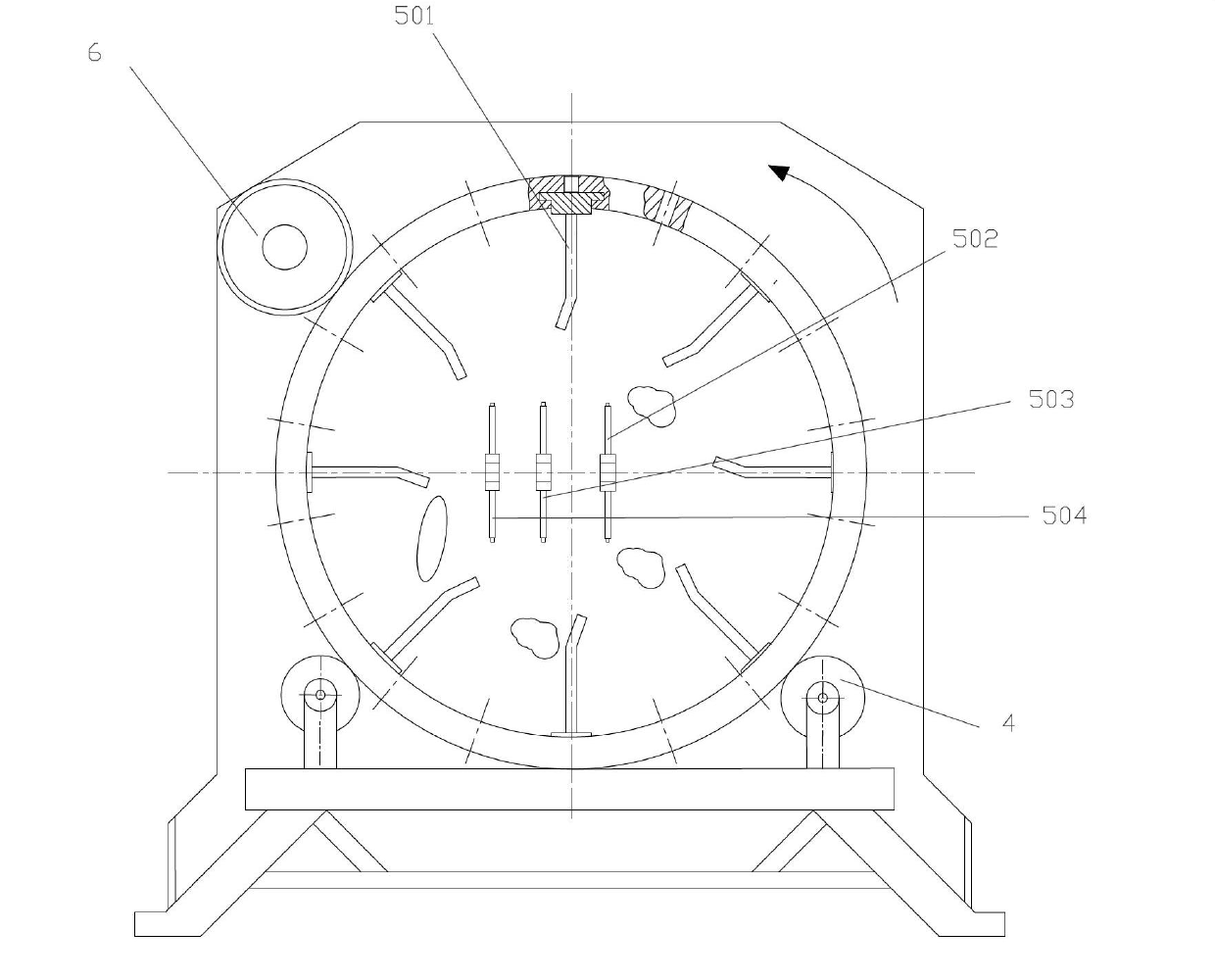

[0063] see Figure 1 to Figure 10 As shown, in this embodiment, the composition and weight percentage of the briquette fuel mixed with the combustible components of the garbage and the coal liquefaction residue are: 62.0% of the combustible components of household garbage, 28.0% of the coal liquefaction residue, and 10.0% of calcium hydroxide. Proceed as follows:

[0064] (1) The municipal solid waste is separated into long strips of plastic and textiles through the broken bags and picking and hanging of the two-stage drum screen, and then the plastic, waste paper and Textile scraps, the double-chamber multi-function wind separator separates plastic, waste paper and textile scraps and separates the combustible components of household waste composed of waste paper and textiles after further wind separation;

[0065] (2) Dry the combustible components of household waste at a temperature of 200°C to reduce the moisture content to 20%;

[0066] (3) Use shear crusher to crush com...

Embodiment 2

[0078] In this embodiment, the composition and mass percentage of the briquette fuel are: 70.0% of the combustible components of household waste, 21.0% of coal liquefaction residue, and 9.0% of calcium hydroxide. The drying temperature in the preparation step (2) was 230° C., the preparation step (3) was stored for 20 minutes, and other steps were the same as those in Example 1.

Embodiment 3

[0080] In this embodiment, the composition and mass percentage of the briquette fuel are: 70.0% of the combustible components of household garbage, 21.0% of coal liquefaction residue, and 9.0% of magnesium hydroxide. The drying temperature in the preparation step (2) was 230° C., the preparation step (3) was stored for 20 minutes, and other steps were the same as those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com