Composite detachable step riveting nut

A technology for riveting nuts and steps, which is applied in the direction of nuts, connecting components, threaded fasteners, etc., to achieve the effects of preventing easy slipping, improving the scope of application, and improving shear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

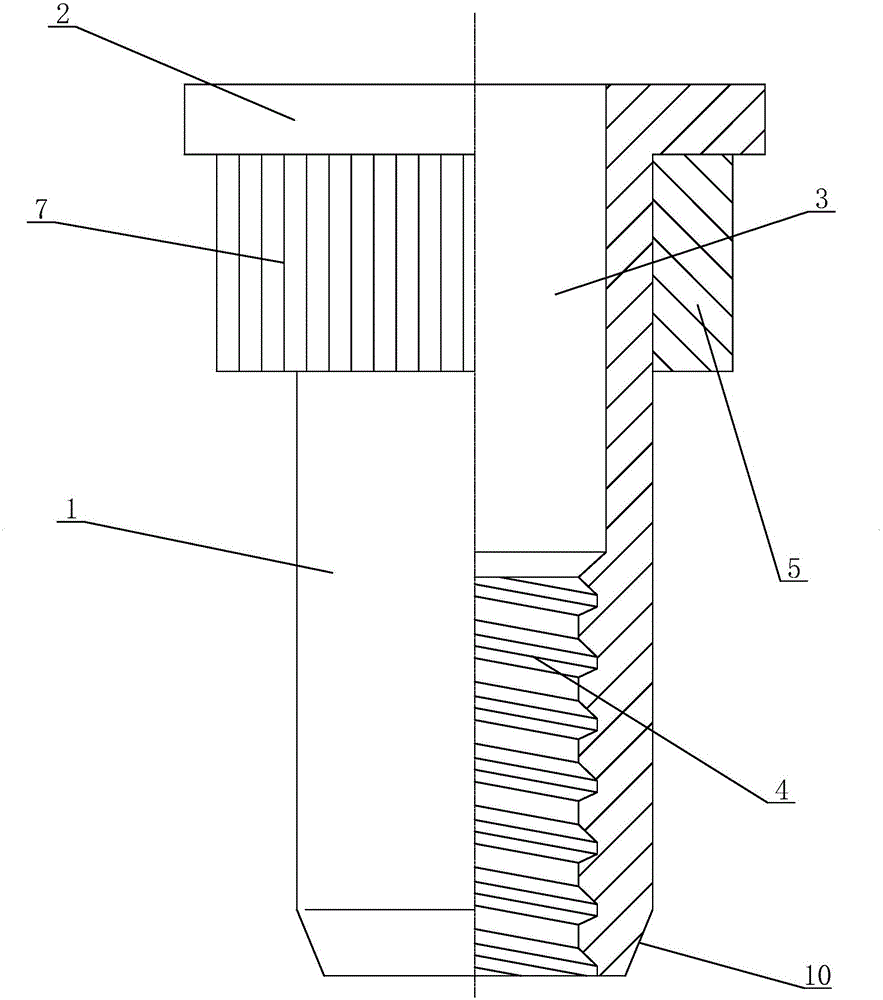

[0015] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

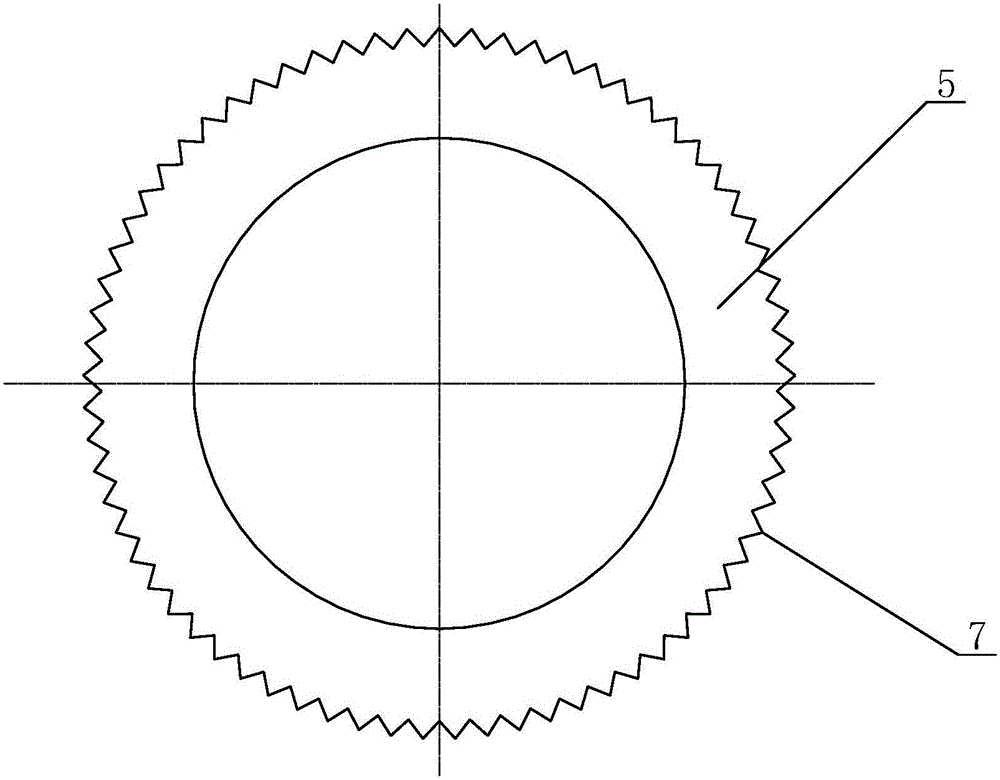

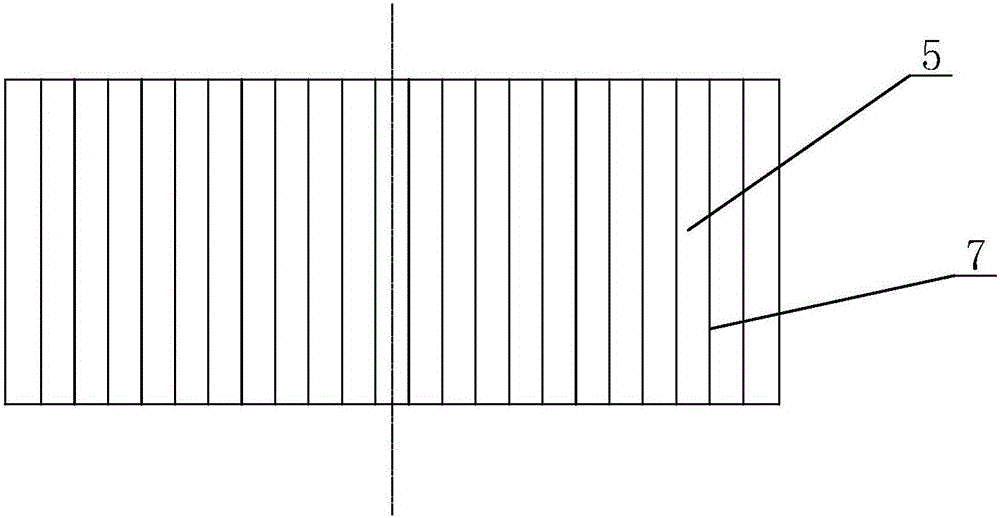

[0016] see Figure 1 to Figure 4 As shown, in this embodiment, a composite detachable stepped riveting nut includes a riveting tube body 1, the head end of the riveting tube body 1 is provided with an outwardly extending brim body 2, and the riveting tube body 1 A large step hole 3 is opened inside, and the bottom of the large step hole 3 is provided with a threaded hole 4. The riveting tube body 1 is provided with an inner lining collar 5 that can be freely disassembled and selected according to the size of the pre-hole of the riveted workpiece. The inner hole of the inner lining collar 5 is set in accordance with the outer diameter of the riveting tube body 1, the height of the inner lining collar 4 is consistent with the large pre-hole riveted workpiece 6, and the outer wall of the inner lining c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com