Coupling unit for connecting a drive with an output

A drive unit and coupling technology, applied in the direction of couplings, elastic couplings, mechanical equipment, etc., can solve the problem of reducing the angle compensation capability of couplings, limiting angular deviation and axial deviation, limiting rotational torque, etc. problem, to achieve the effect of compensating axial deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

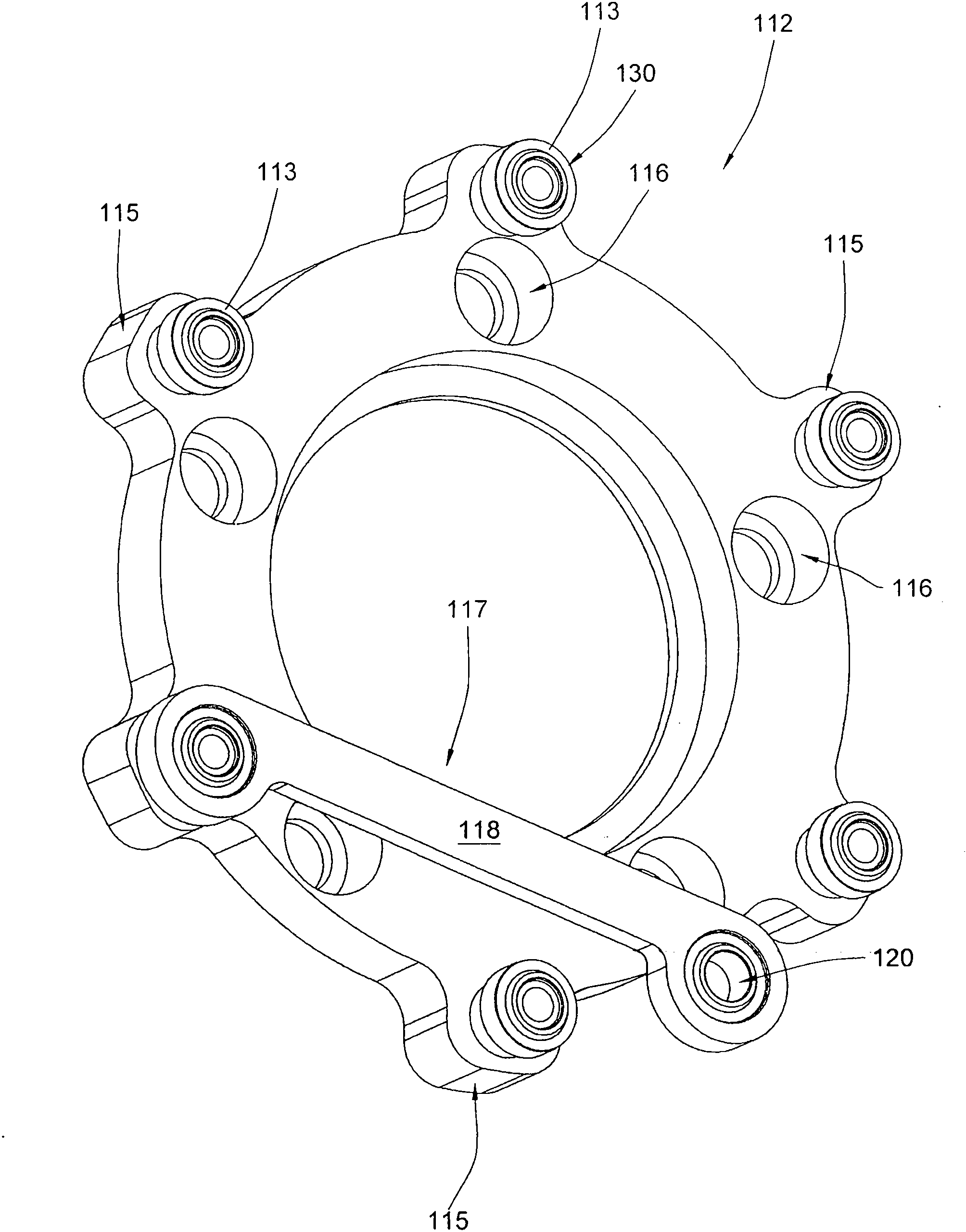

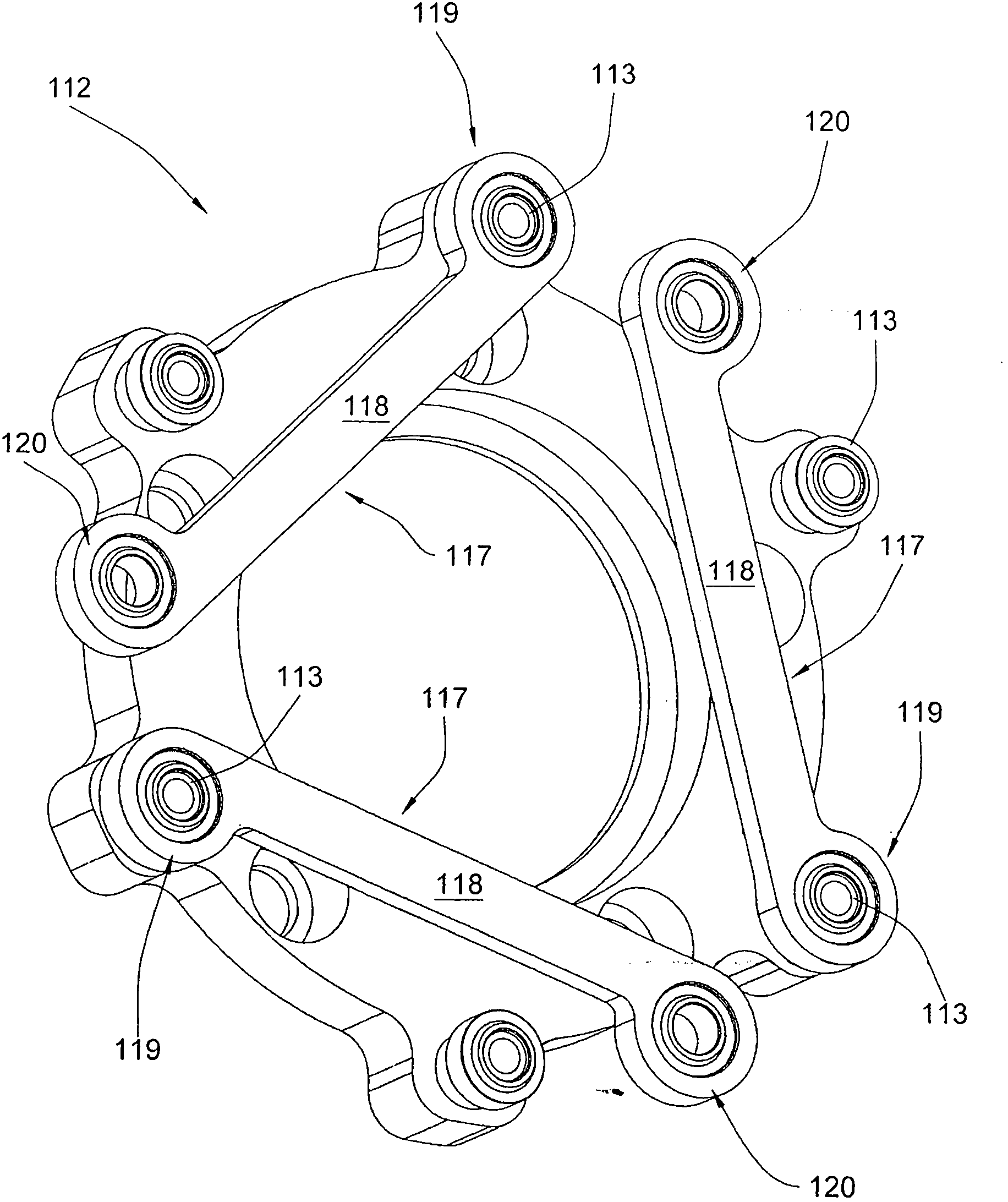

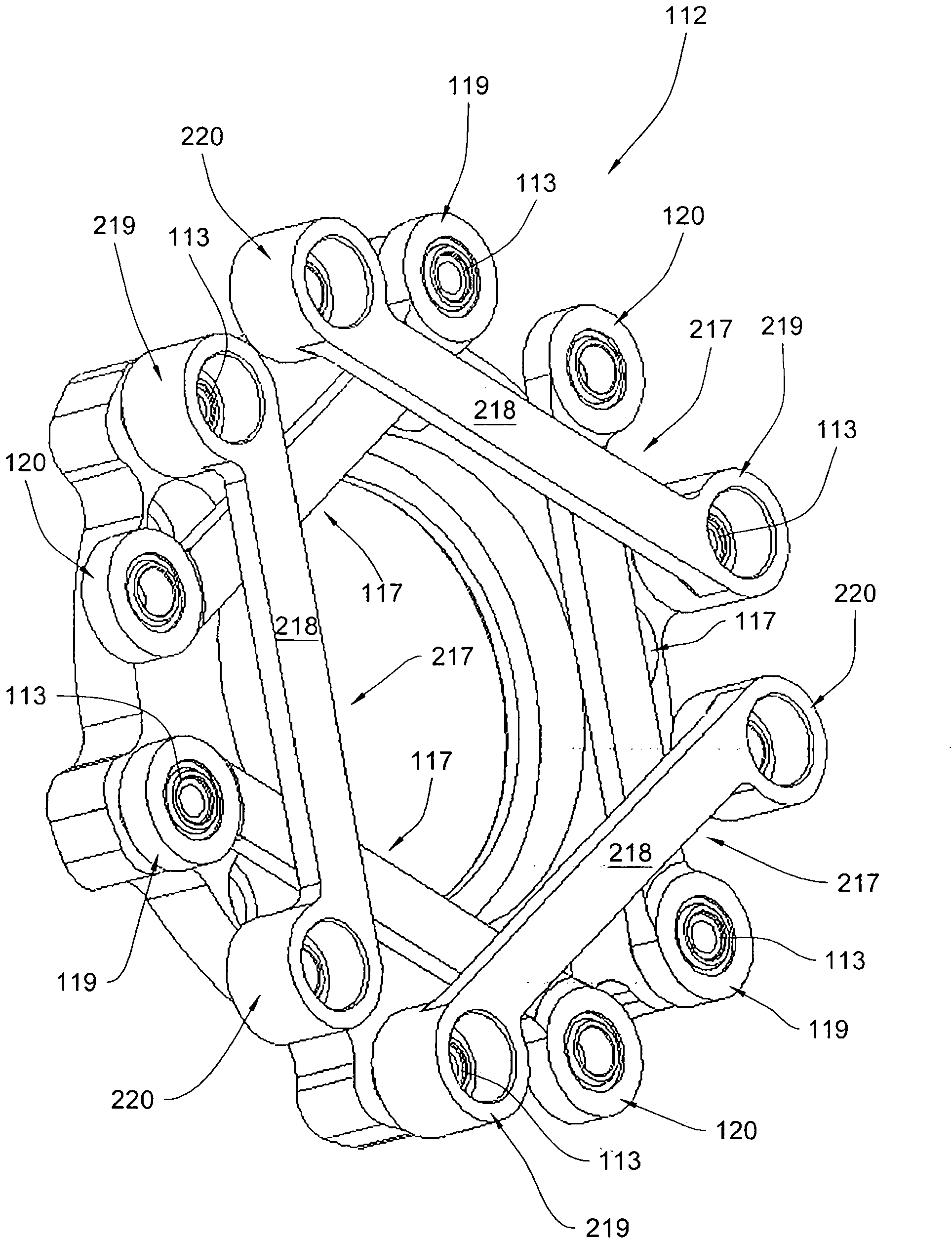

[0037] exist Figure 4 with Figure 5 , the coupling is indicated generally by the reference numeral 100 .

[0038] The coupling 100 includes two coupling units generally indicated by reference numeral 110 . The coupling units 110 are arranged axially one behind the other in the force flow direction KF and are coupled to one another via a shaft 114 . The force flow flows from a drive unit AN (not shown) to an output unit AB (also not shown). A structural element described hereinafter as drive unit side is generally arranged on the drive unit side relative to another structural element, and a structural element indicated hereinafter as driven unit side is generally arranged on the driven unit side relative to another structural element.

[0039] exist figure 1A drive-unit-side connecting device 112 is shown in , which is also referred to as a drive-unit-side flange 112 or a drive-unit-side flange ring 112 . The flange 112 is annular and is provided with star-ray-like proje...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com