Combined screw impeller wind power generation system

A technology of wind power generation system and helical impeller, which is applied in wind turbine components, wind energy power generation, wind turbines, etc., can solve the problems of difficulty in processing and manufacturing, and achieve the effects of increasing rotational torque, reducing starting inertia, and reducing frictional resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

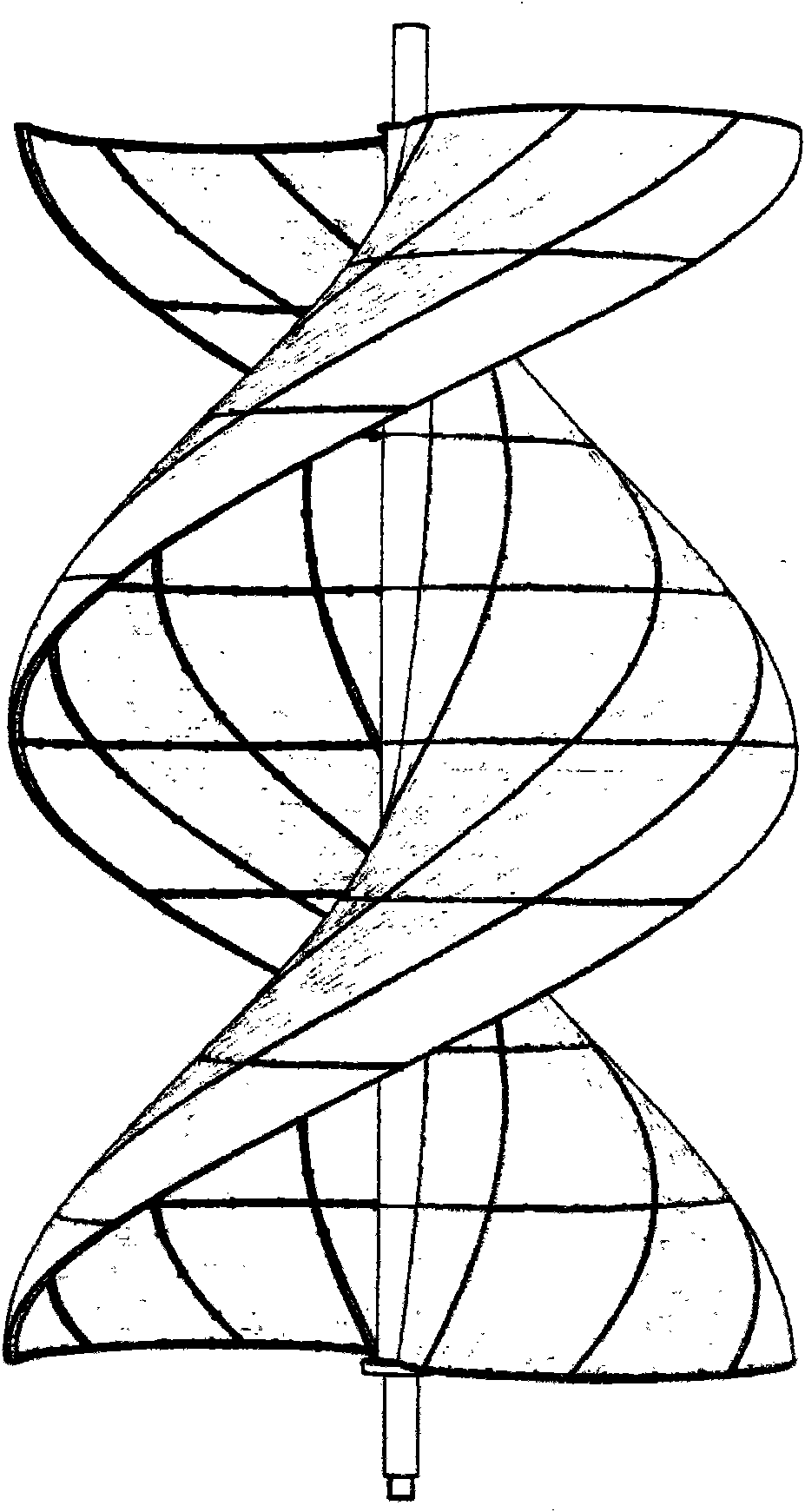

[0036] Embodiment 1: This embodiment is a large-scale wind power generation system, its composition and structure are as follows Figure 14 shown.

[0037] This embodiment shows that the wind power generation system is composed of the following parts: helical impeller, transmission mechanism, multiple generator sets, magnetic suspension bearing, wind speed and direction instrument, power storage device and control device.

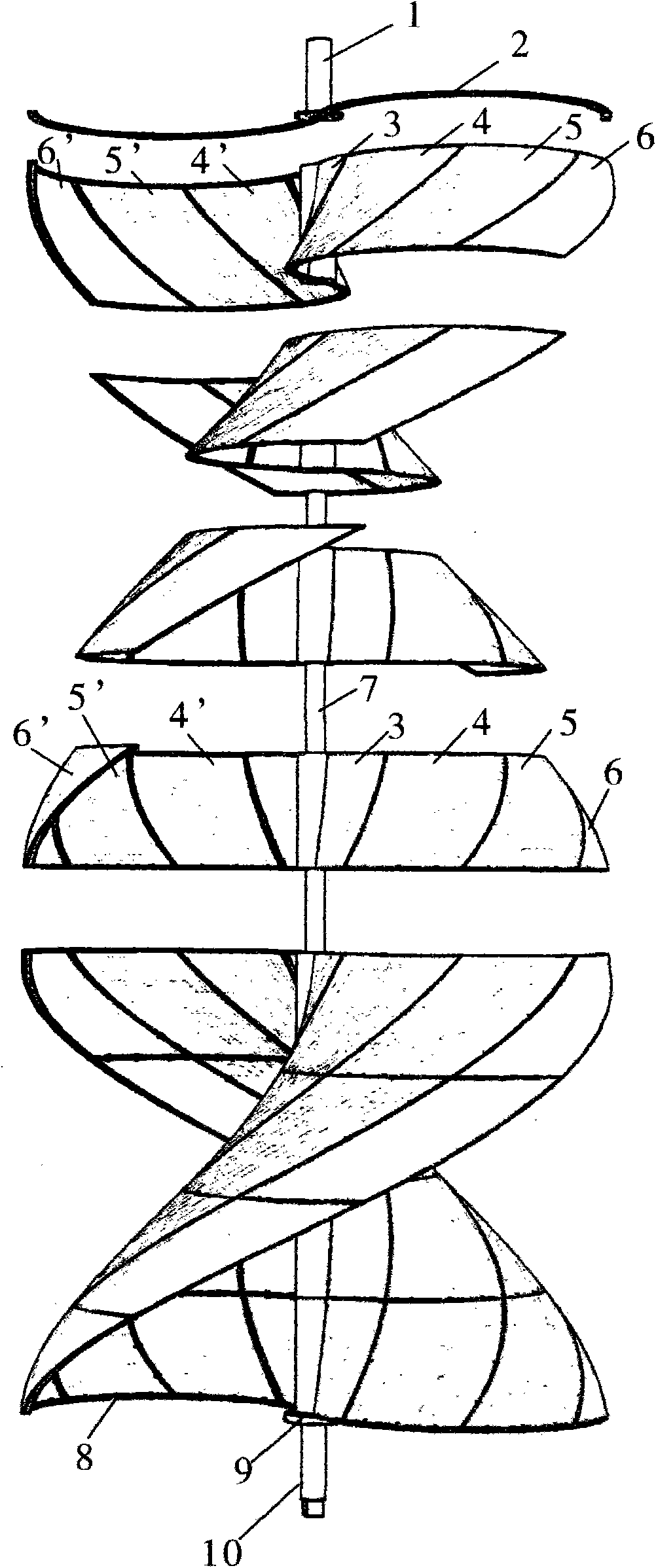

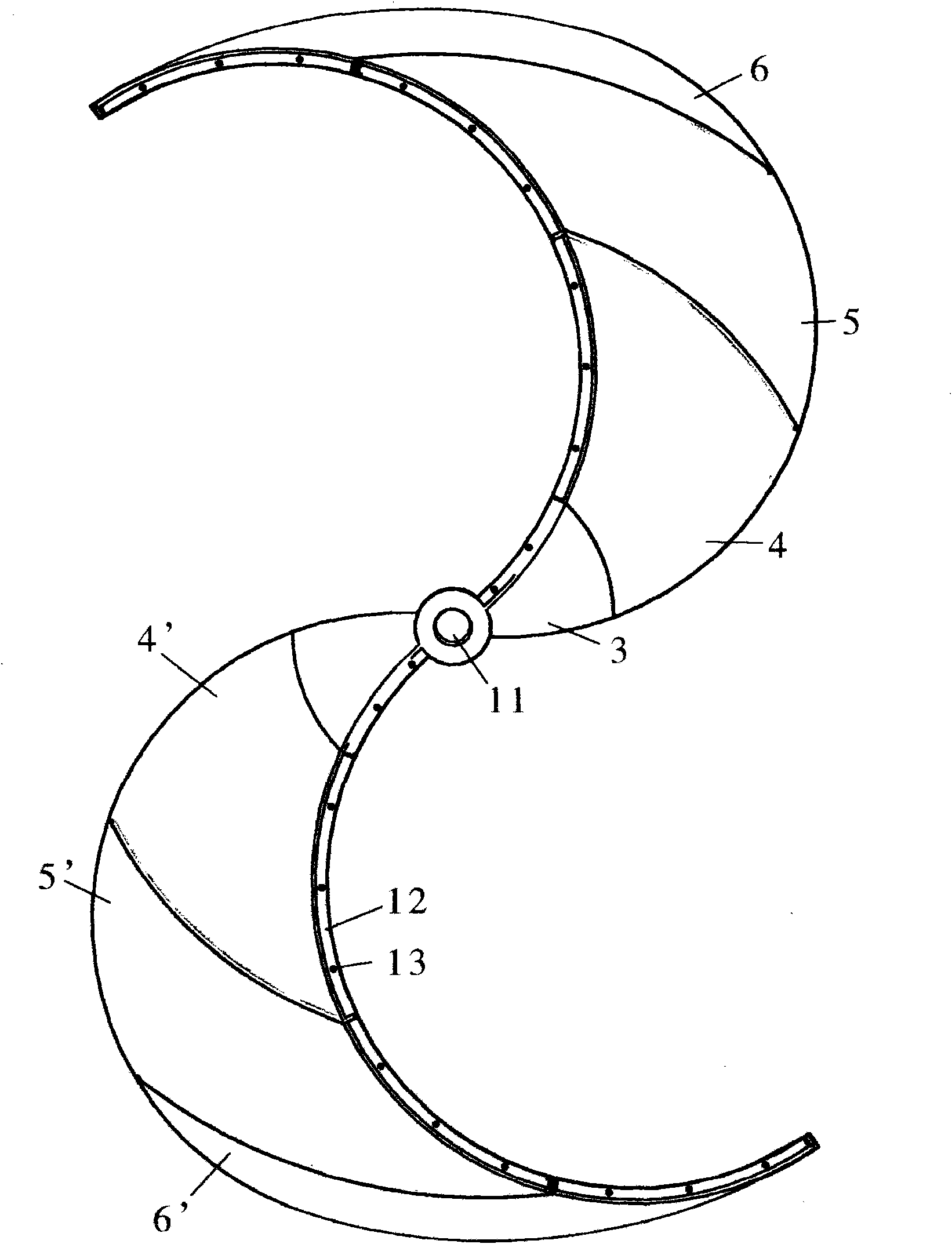

[0038] The structure of the spiral impeller in this embodiment is as follows: figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9. The helical impeller is composed of impeller upper shaft pin 1, impeller upper end S piece, central shaft member 3, middle I member 4, middle II member 5, edge member 6, impeller center shaft 7, impeller lower end S piece, impeller lower shaft pin 9 Composition, the central axis member 3 is located at the central axis position, the middle I member 4, the middle II member 5 and the edge member 6 are radially and symmetrically arranged on both ...

Embodiment 2

[0043] The structure of this embodiment is as follows Figure 18 shown.

[0044] This embodiment provides a small-sized spiral impeller wind power generation device, which can be used for street lighting. The device is fixed to a street light pole 55 through an upper beam 48 and a lower beam 54 . This device transmission annular gear 51, transmission gear 50 and three generator sets 49 are all arranged on the helical impeller directly above, and transmission gear 50 is fixed with the generator rotor shaft.

[0045] Due to the relatively small size of the helical impeller in this embodiment, one central shaft member, two intermediate members, and two edge members can be used to assemble and combine. In this way, the helical impeller can be realized only by making molds for three sub-components. If the diameter of the helical impeller is even smaller, the helical impeller can also be molded axially in sections, so that only one pair of molds is needed to realize the helical imp...

Embodiment 3

[0048] This embodiment provides a small independent spiral impeller wind power generation device, the composition and structure of the device are as follows Figure 19 shown.

[0049] In this embodiment, the support frame base 61 is fixed by the support frame fastening steel cable, the helical impeller 58 is fixed on the annular gear 59, and the rotor shafts of the three generator sets 60 are meshed with the annular gear through transmission gears. The manufacturing method of the spiral impeller of this embodiment is the same as that of Embodiment 2.

[0050] This embodiment is more suitable to be installed at the tuyere with steep terrain.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com