Punch-cutting mining method and punch-cutting mining machine implementing method

A body and frame technology, applied in earthwork drilling, slitting machinery, driving devices, etc., can solve problems such as gluing or even seizure, equipment failure to operate normally, and high power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

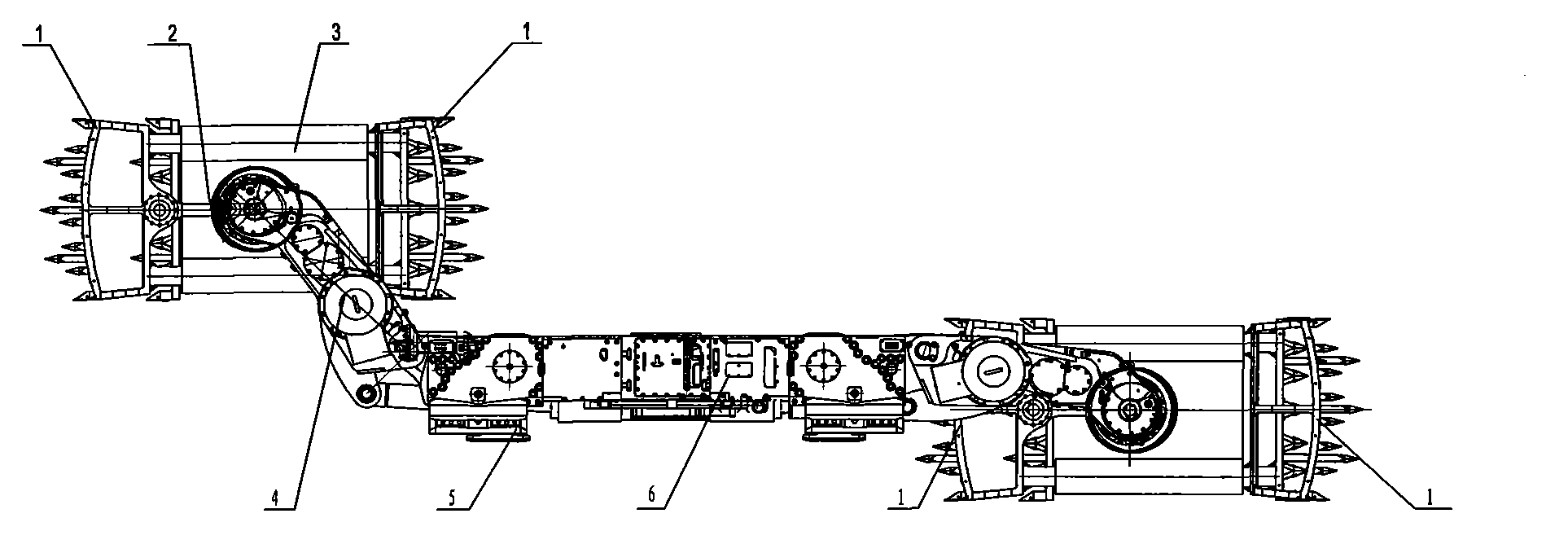

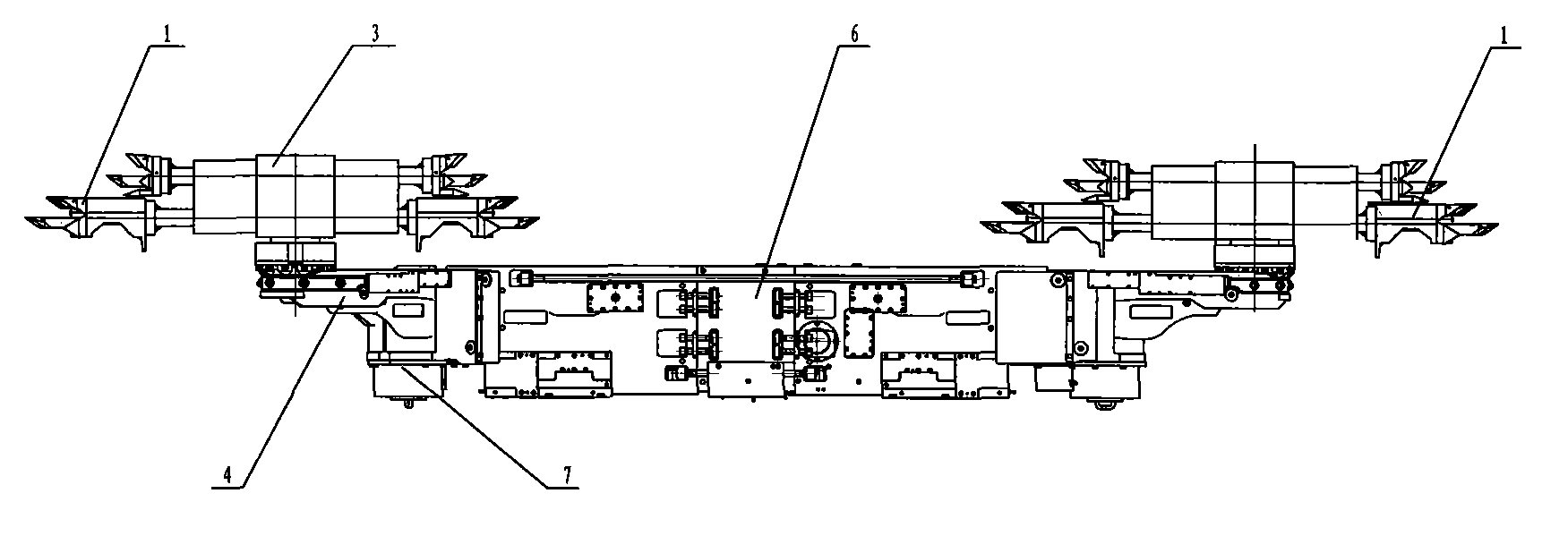

[0597] Figure 1 to Figure 4 It is the punching mining machine described in embodiment 1, which includes a fuselage 6, a walking part 5, a reciprocating impact part 3, and the reciprocating impact part 3 includes a guiding device 8, an impact driving device 7, and the guiding device 8 and The impact driving device 7 is separated or connected. The guide device 8 includes an impact guide 18. The reciprocating impact part 3 also includes an impact head 1. Both ends of the impact guide 18 are provided with an impact head 1. The impact drive 7 includes a power impact member 2. , the power impact part 2 drives the impact head 1 to reciprocate, the impact head 1 impacts the coal wall or rock wall to realize mining and falling materials, the power impact part 2 and the impact guide 18 are separated, the body 6 includes a frame 53, a lifting device, and The device is arranged on the frame 53, the reciprocating impact part 3 is arranged on the lifting device, and the running part 5 is a...

Embodiment 2

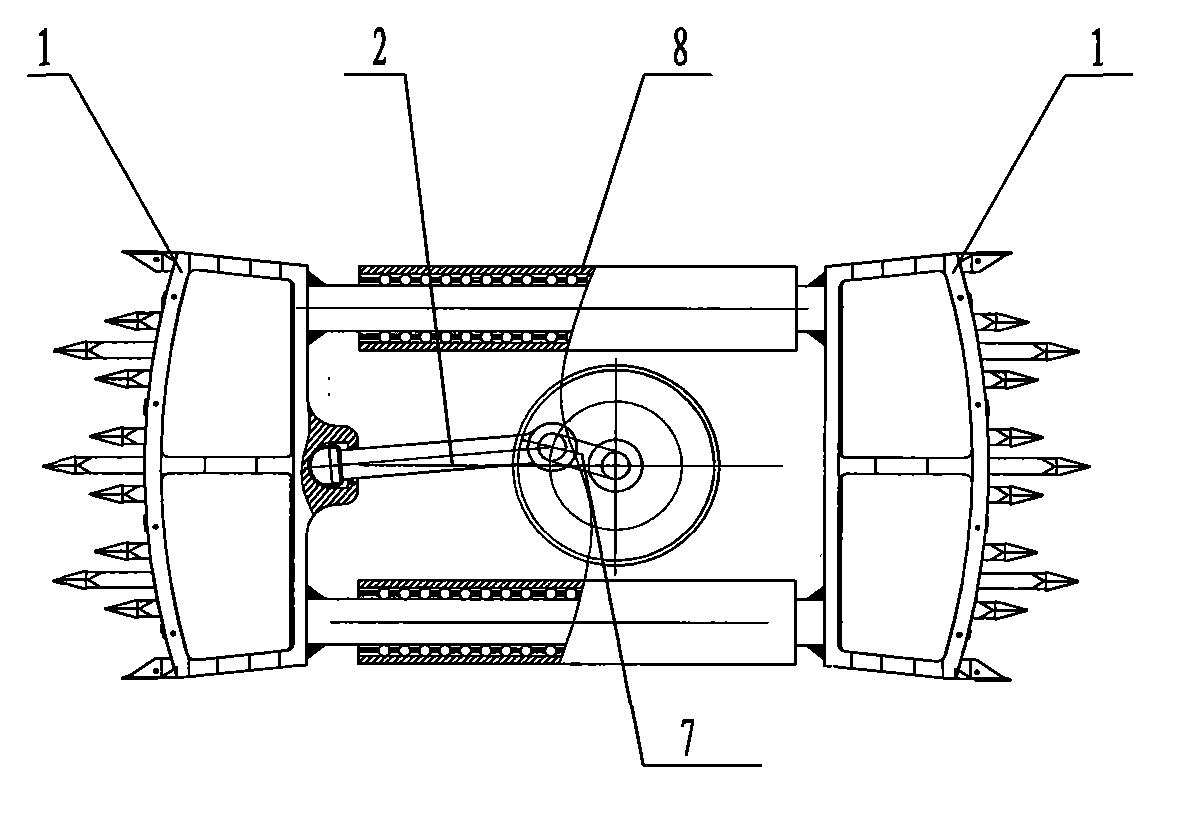

[0613] Figure 5 to Figure 8 For the punching mining machine described in embodiment 2, such as Figure 6 As shown, the guide device 8 includes a rolling reciprocating device 10, the rolling reciprocating device 10 includes rolling elements, rolling element supports 170, and rolling impact guides 9, and the rolling elements are arranged between the rolling element supports 170 and the rolling impact guides 9, The rolling body, the rolling body support 170, and the rolling impact guide 9 closely cooperate to make the rolling body support the rolling impact guide 9 to reciprocate through rolling friction; Figure 7 As shown, the sliding guide device 8 includes a sliding impact guide 13 and a sliding support 14. Lubricating liquid or lubricating powder is arranged between the sliding impact guide 13 and the sliding support 14. The dynamic impact member 2 is connected with the impact head 1, and the sliding The guide device 8 supports the reciprocating movement of the sliding imp...

Embodiment 3

[0621] Figure 9 It is the punching mining machine described in Embodiment 3, the reciprocating impact part 3 is arranged on the side of the lifting device or the frame 53, the running part 5 drives the fuselage 6 to move forward and backward, and the power impact part 2 drives the impact guide part 18 Reciprocating movement, the impact guide 18 drives the impact head 1 to impact the coal wall or the rock wall, so as to realize the forward mining and falling of materials and the backward mining and falling of materials without turning the fuselage 6.

[0622] According to the above structure, the present invention also includes a method of flushing and mining, which is realized by the following steps:

[0623] The reciprocating impact part 3 is arranged on the side of the lifting device or the frame 53;

[0624] Make the walking part 5 drive the fuselage 6 to move forward, make the power impact part 2 drive the impact guide 18 to reciprocate, and make the impact guide 18 driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com