Vehicle cowl structure

A front cover, vehicle technology, applied to the upper structure, vehicle parts, upper structure sub-assembly, etc., can solve the problems of mismatching appearance, increased manufacturing cost, deterioration of pedestrian protection performance, air intake formability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, exemplary embodiments of the present invention will be described with reference to the accompanying drawings.

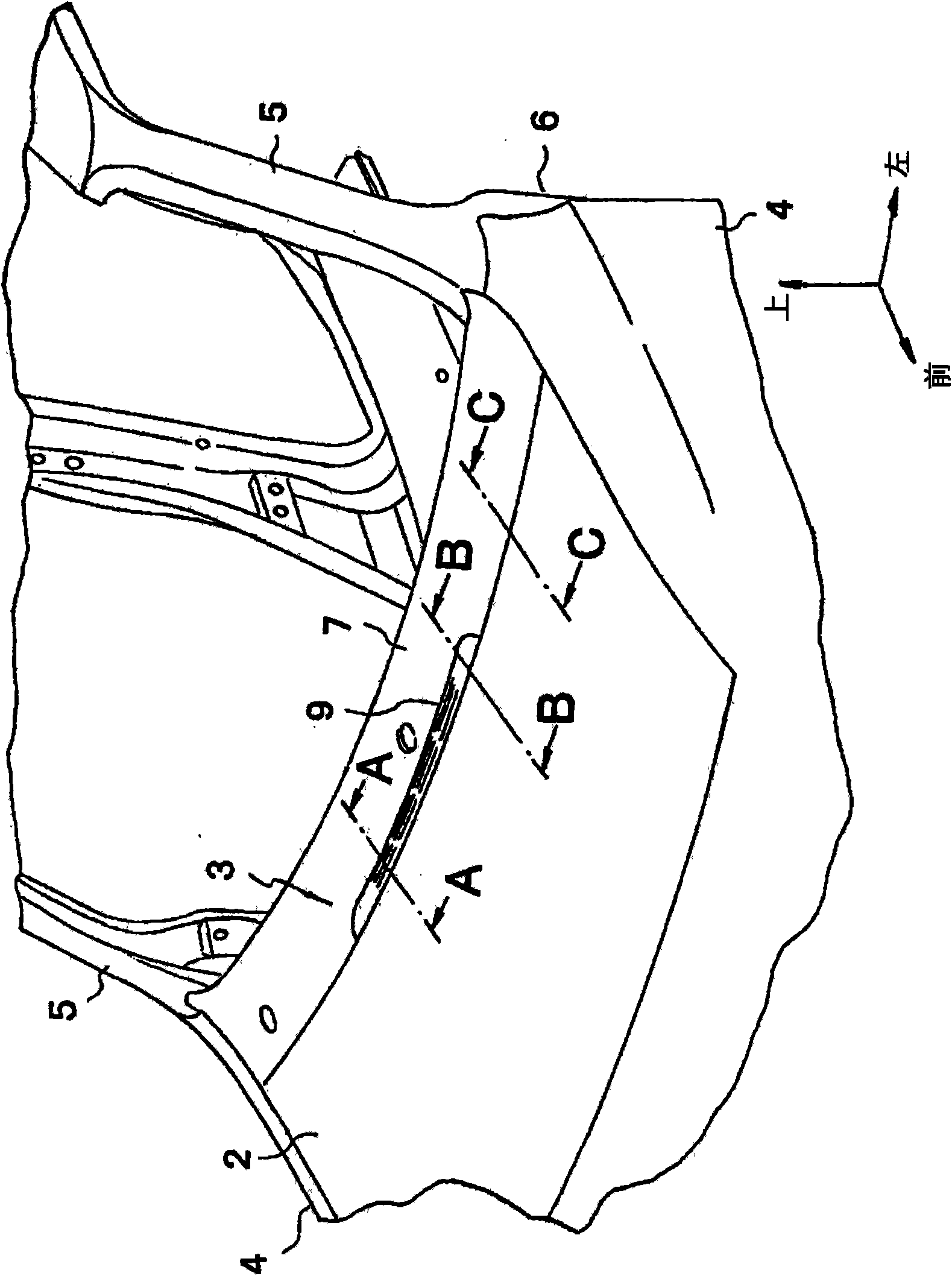

[0031] Such as Figures 1 to 4 As shown, the cowl part 3 extends along the width direction of the vehicle between the lower end of the windshield 1 and the rear end of the hood 2, wherein the windshield 1 is arranged at the front of the vehicle, and the hood 2 is arranged at the front The front side of the window pane 1. A pair of right and left metal fenders 4 are provided adjacent to left and right ends of the cowl portion 3 . A pair of right and left body bodies 6 and a pair of left and right front pillars 5 are provided on the rear side of the cowl portion 3 along the boundary line between the fender 4 and the cowl portion 3 .

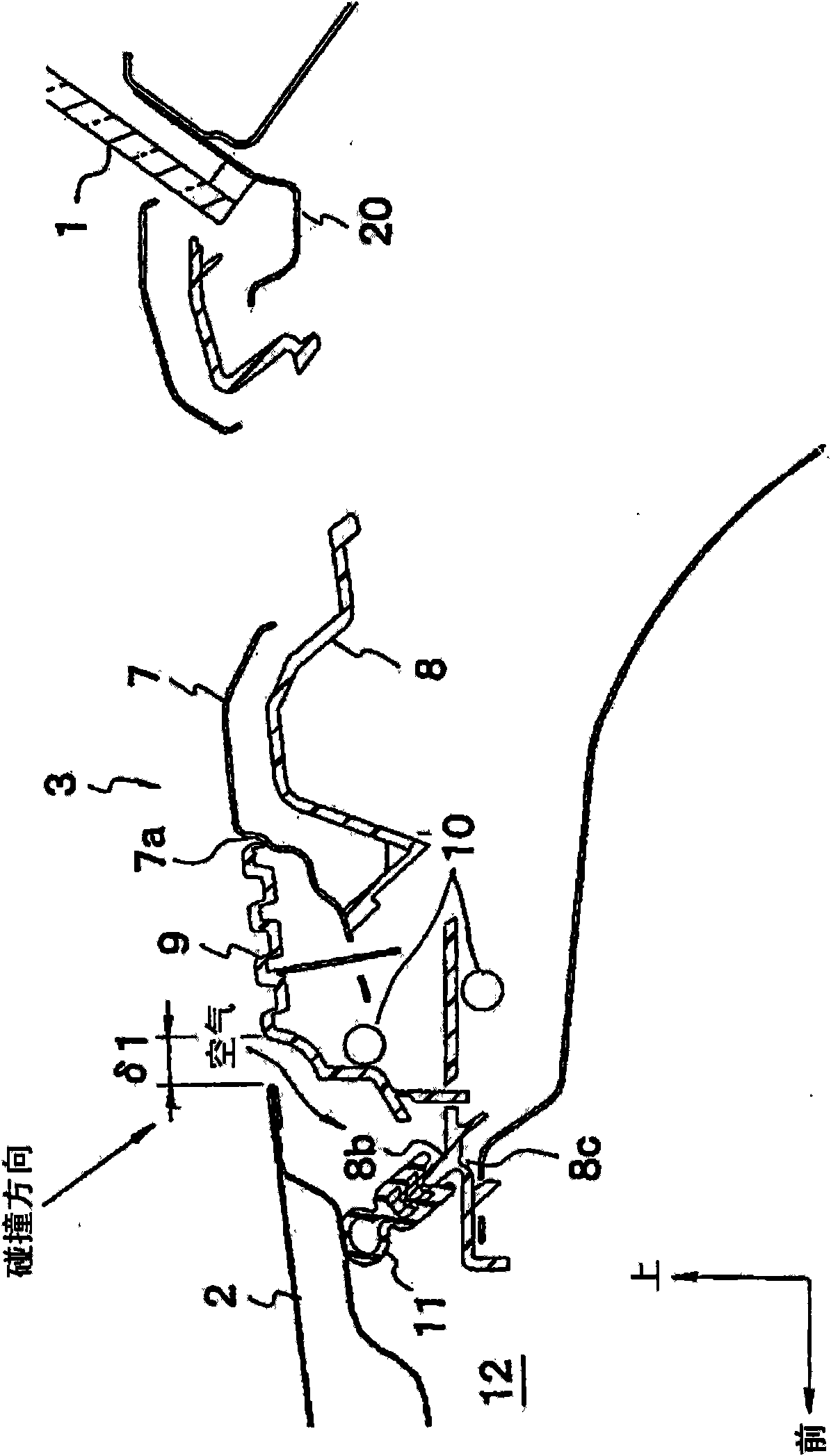

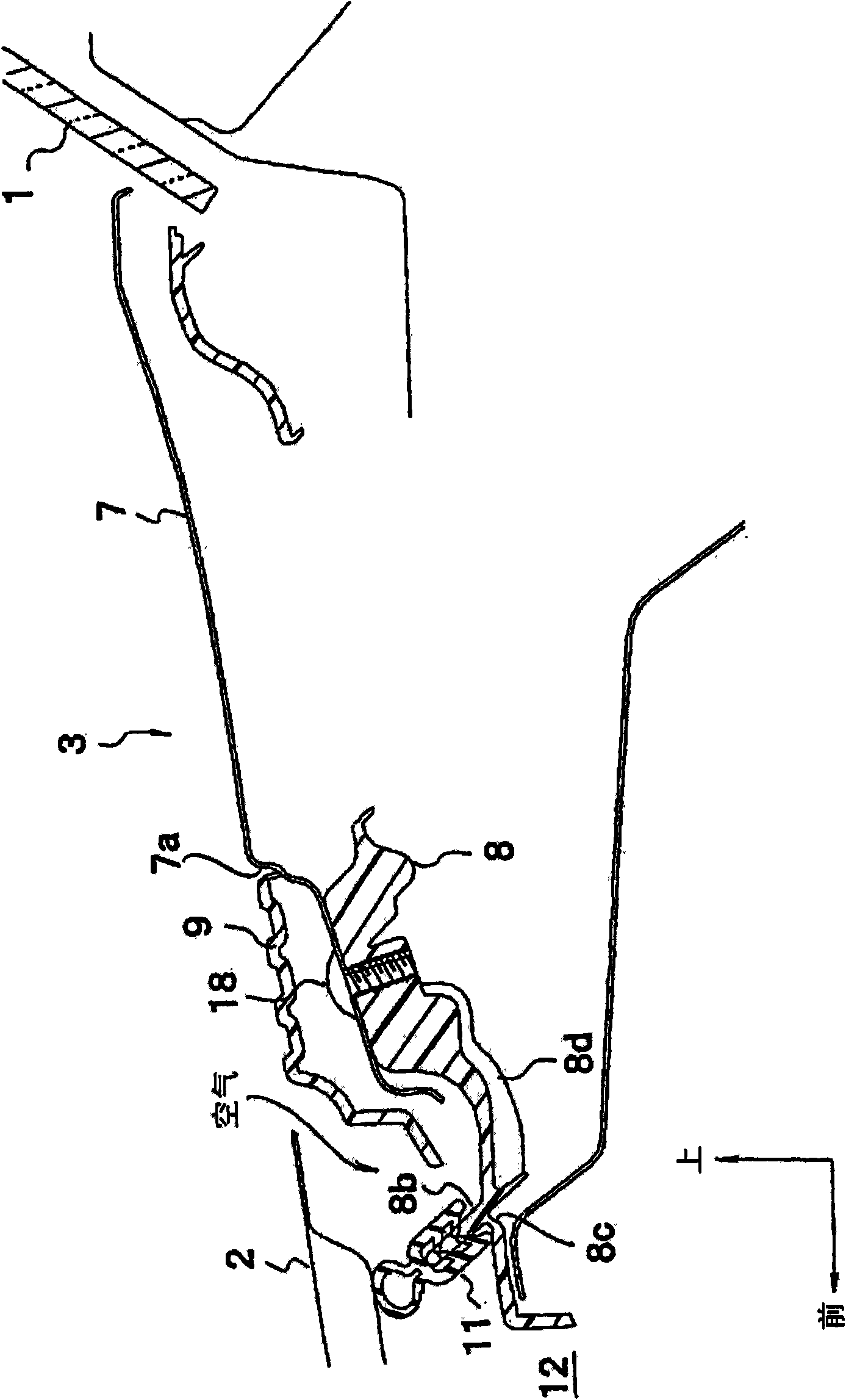

[0032] Such as Figures 2 to 4 As shown, the cowl portion 3 has a two-layer structure in which a resin cowl cover 8 is provided under a metal cowl 7 having a design surface continuous to the hood 2 . "Design surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com