Automatic screw locking mechanism for molded case circuit breaker base and locking and attaching method

A technology for molded case circuit breakers and automatic screw locking, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low degree of automation, low work efficiency, and high failure rate of locking screws, and achieves high degree of automation and improved Production efficiency, accurate screw locking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

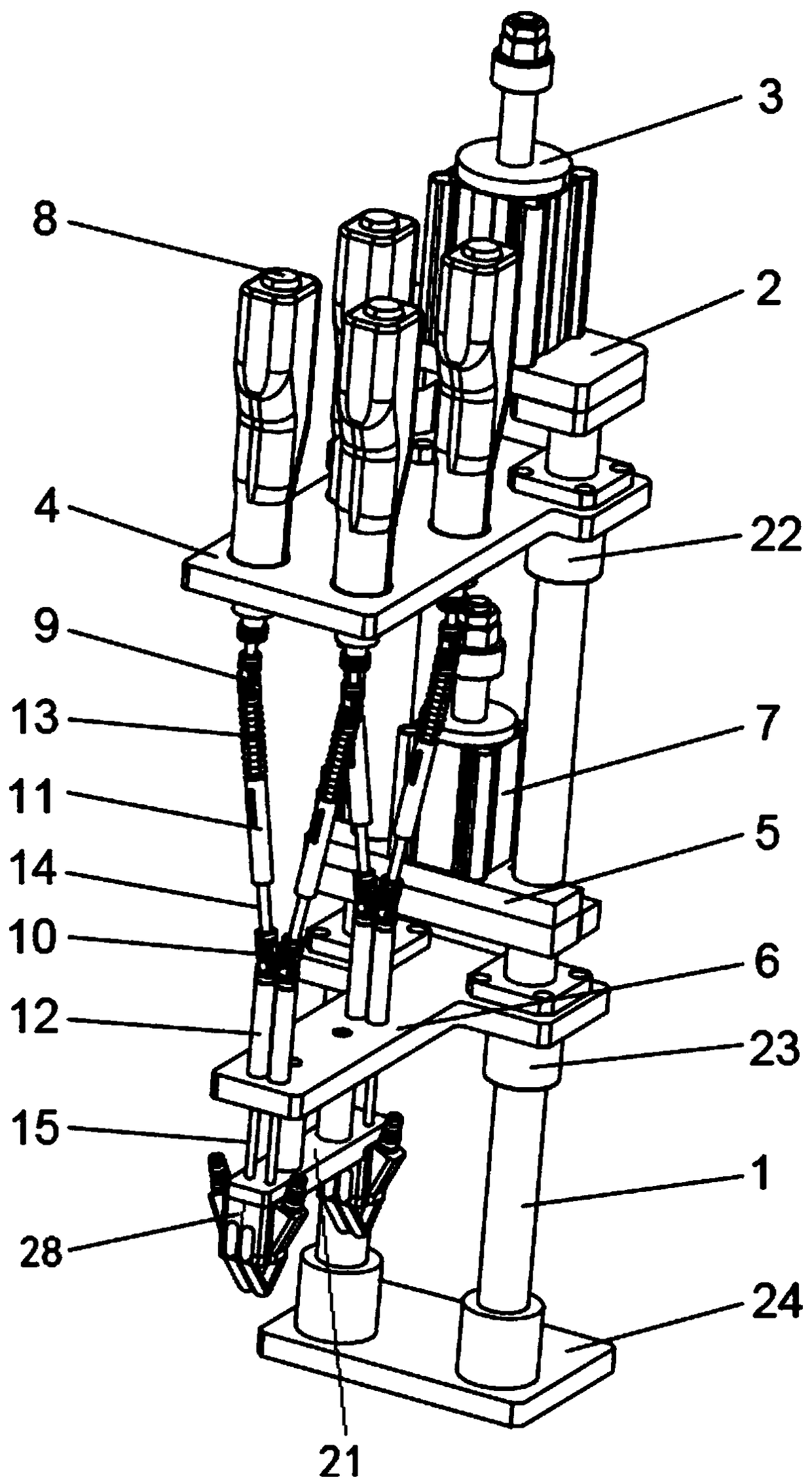

[0055] Such as figure 1 As shown, in the automatic locking screw mechanism of the present invention, there are 4 locking mechanisms and 4 screw chucks 28; 4 screwdrivers 15 are arranged in 2 rows, with 2 in each row; a screwdriver 15 corresponds to a screw chuck 28, The bit of each screwdriver 15 faces the first through hole 2806 of a screw chuck 28 .

Embodiment 2

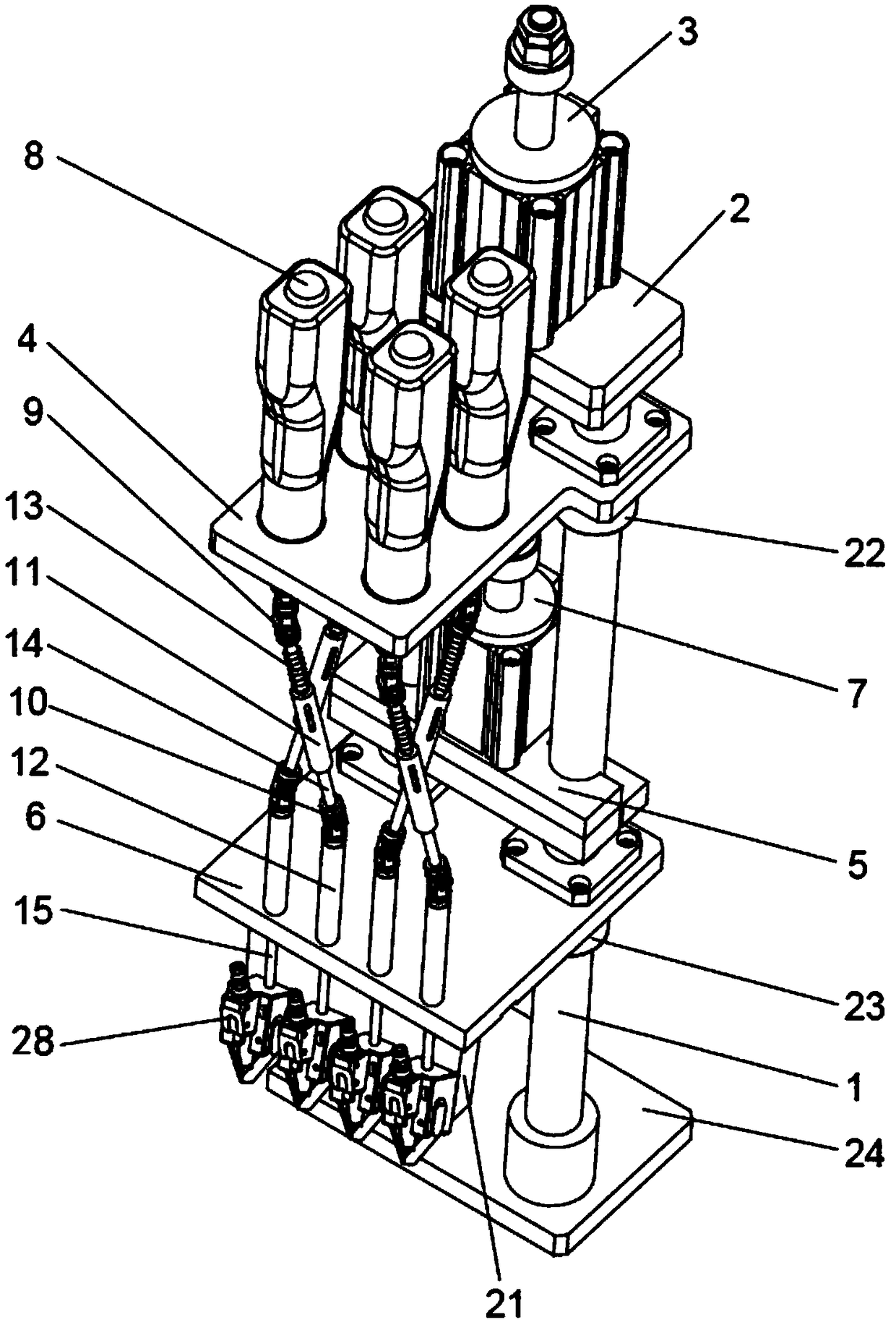

[0057] Such as figure 2 As shown, in the automatic locking screw mechanism of the present invention, there are 4 locking mechanisms and 4 screw chucks 28; 4 screwdrivers 15 are arranged in the shape of "one"; a screwdriver 15 corresponds to a screw chuck 28, and each screwdriver The cutter head of 15 faces the first through hole 2806 of a screw chuck 28.

Embodiment 3

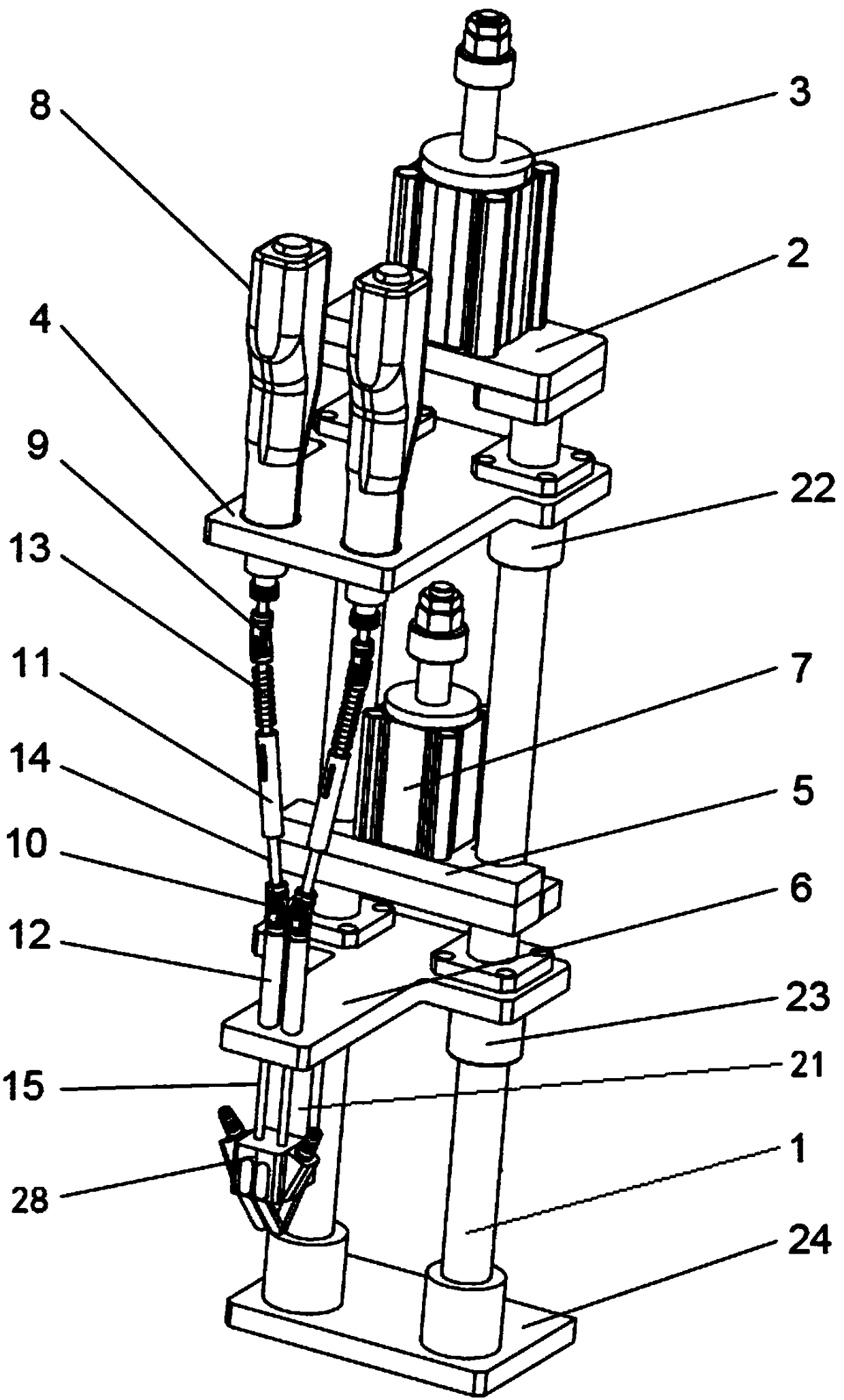

[0059] Such as image 3 As shown, in the automatic locking screw mechanism of the present invention, there are 2 locking mechanisms and 2 screw chucks 28; 2 screwdrivers 15 are arranged in the shape of "one"; a screwdriver 15 corresponds to a screw chuck 28, and each screwdriver The cutter head of 15 faces the first through hole 2806 of a screw chuck 28.

[0060] The structure 32 of the base of the 4P molded case circuit breaker equipped with component products, the structure of the base 33 of the 3P molded case circuit breaker equipped with component products, and the structure of the base 34 of the 2P molded case circuit breaker equipped with component products are introduced as follows:

[0061] Such as Figure 12 As shown, the 4P molded case circuit breaker base 32 equipped with component products is sequentially provided with the first line screw lower hole group 3201, the first static contact screw lower hole group 3202, and the first frame screw lower hole group. Grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com