Plain bearing and method for producing same

A technology of sliding bearings and shaft holes, which is applied in the field of sliding bearings and pumps, can solve the problems of increased impeller rotational torque, decrease and increase of pump capacity, and achieve the effect of suppressing the increase of impeller rotational torque and reducing sliding resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A sliding bearing and a pump according to Embodiment 1 of the present invention will be described with reference to the drawings. In addition, in this embodiment, an electric water pump used for pressure-feeding cooling water in a hybrid vehicle or the like will be described as an example. Therefore, in this embodiment, the fluid pumped is cooling water.

[0055]

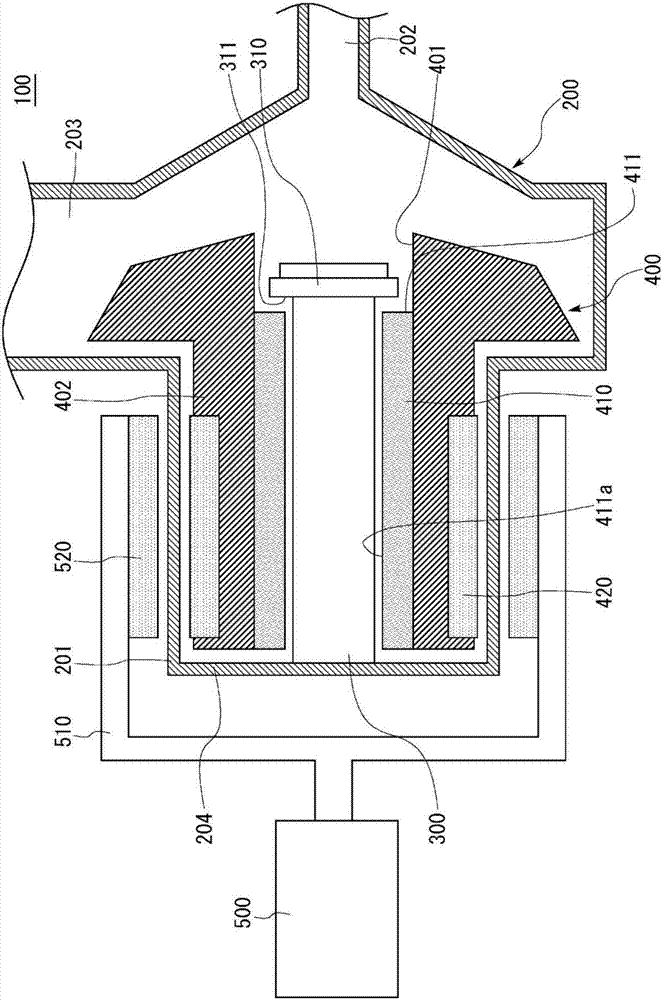

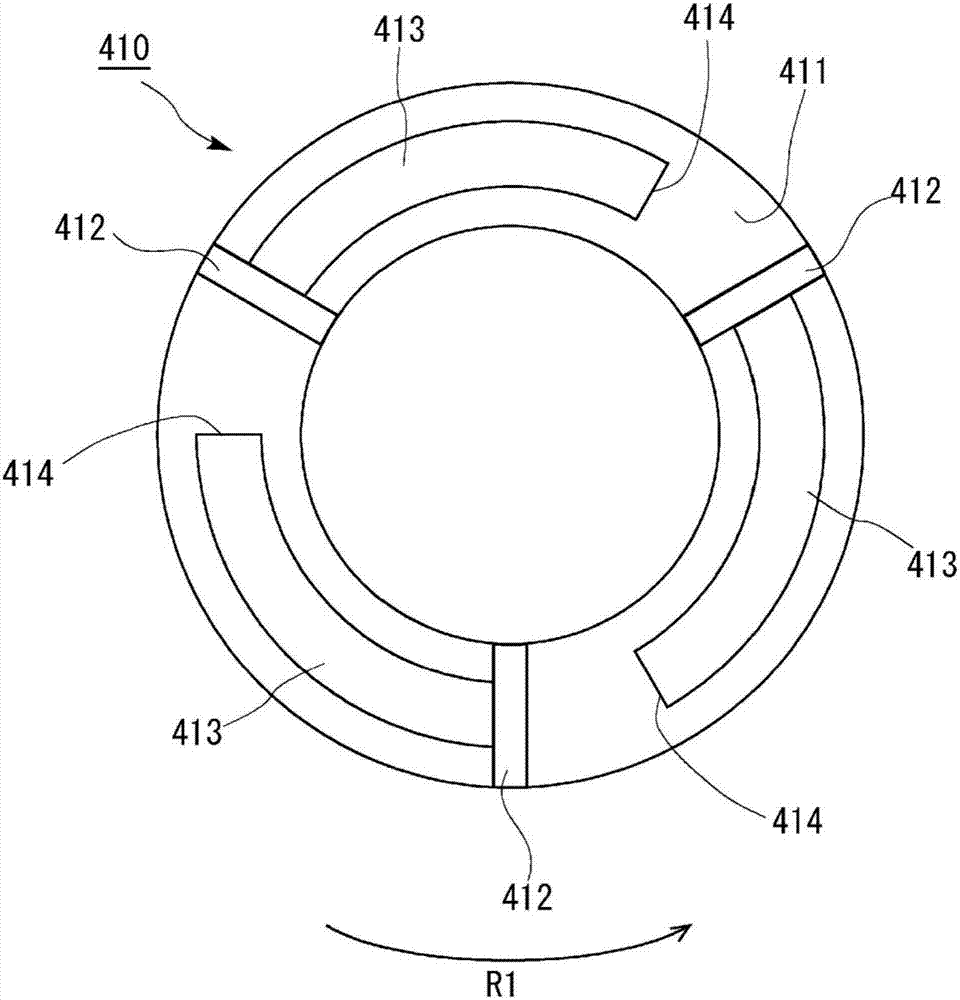

[0056] refer to figure 1 , illustrating the overall structure of the pump of the embodiment of the present invention. figure 1 It is a schematic sectional view of the pump 100 according to the embodiment of the present invention, and is a schematic sectional view cut along a plane including the central axis of the shaft 300 . In addition, for convenience of description, the internal structure is omitted, and basically only the end faces are shown.

[0057]The pump 100 includes a housing 200 , a shaft 300 provided in the housing 200 , and an impeller 400 that rotates with respect to the shaft 300 and pump...

Embodiment 2

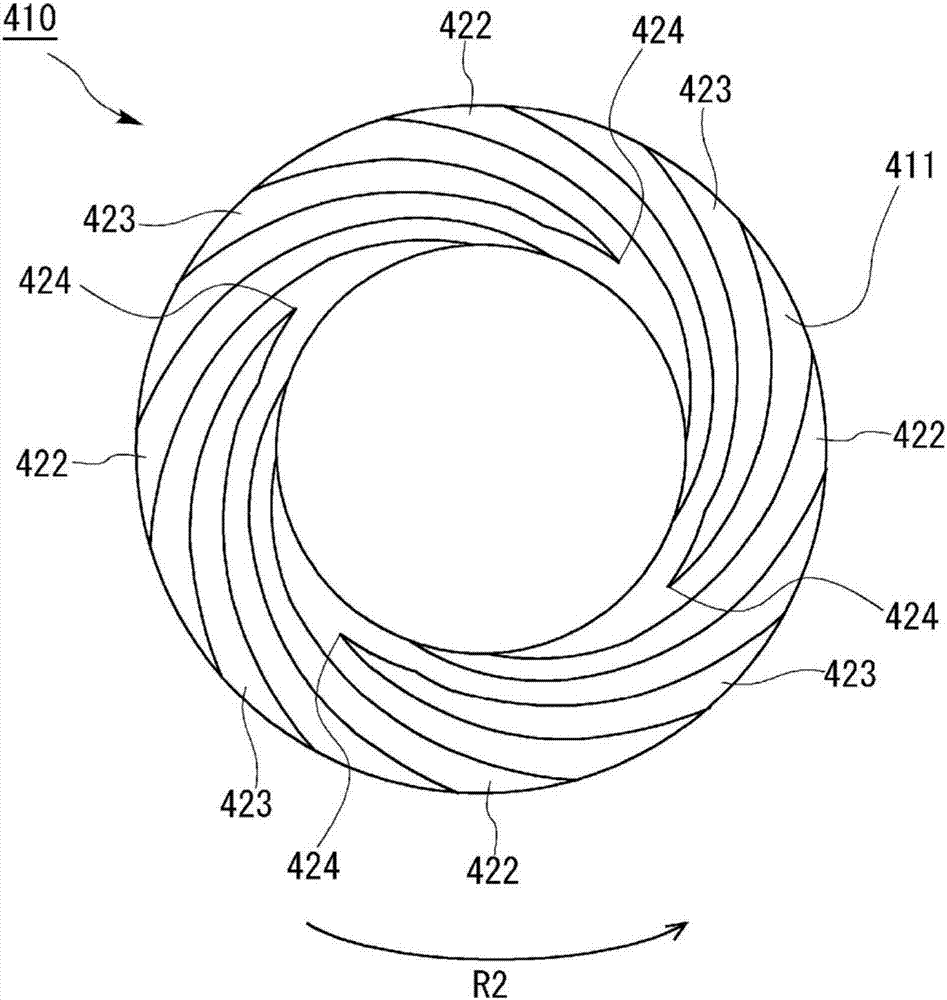

[0073] Then, refer to image 3 Example 2 of the present invention will be described. In this embodiment, only the shapes of the lubricating groove and the dynamic pressure generating groove provided on the end surface 411 of the sliding bearing 410 are different from the shape of the above-mentioned embodiment 1, and the other structures are the same. Therefore, differences will be described below, and descriptions of other structures and functions will be omitted. Also use the same symbol for the same structural part.

[0074] image 3 with the above figure 2 Similarly, it is a diagram when the sliding bearing 410 is viewed from the restricting member 310 side in the axial direction, and shows the structure of the end surface 411 . A lubricating groove 422 and a dynamic pressure generating groove 423 are formed on the end face 411. The lubricating groove 422 communicates with the inner and outer sides in the radial direction, and cooling water is supplied to the end face...

Embodiment 3

[0092] Next, refer to Figure 16 , to illustrate Embodiment 3 of the present invention. The present embodiment differs from the structure of the above-described first embodiment only in that restricting members serving as restricting portions for restricting the axial movement of the sliding bearing 410 are provided on both axial sides of the sliding bearing 410 , and the other structures are the same. Therefore, only the different points will be described below, and descriptions of other structures and functions will be omitted. In addition, the same symbol is used for the same structural part.

[0093] Figure 16 with the above figure 1 Similarly, it is a schematic cross-sectional view of the pump 110 of this embodiment. Pump 110 is equipped with figure 1 In addition to the configuration of the pump 100 shown, a restricting member 320 as a second annular restricting portion is further provided. The restricting portion 320 is fixed to the left side surface 204 in the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com