Direct drive type reciprocating piston IC engine

A technology of reciprocating pistons and internal combustion engines, applied in mechanical equipment, machines/engines, etc., can solve the problems of difficult component configuration, unsatisfactory load bearing state, unsatisfactory wear uniformity, and high manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

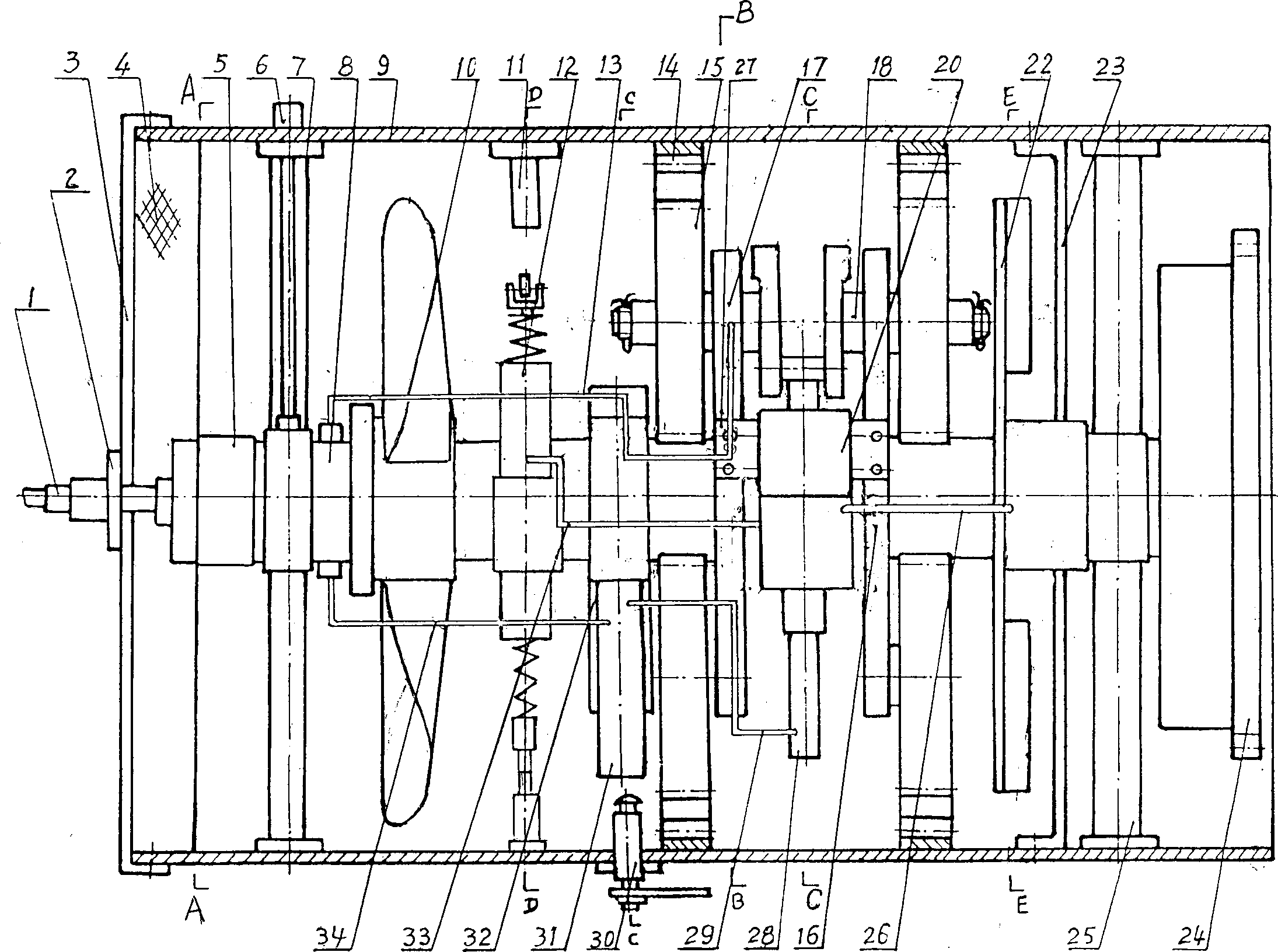

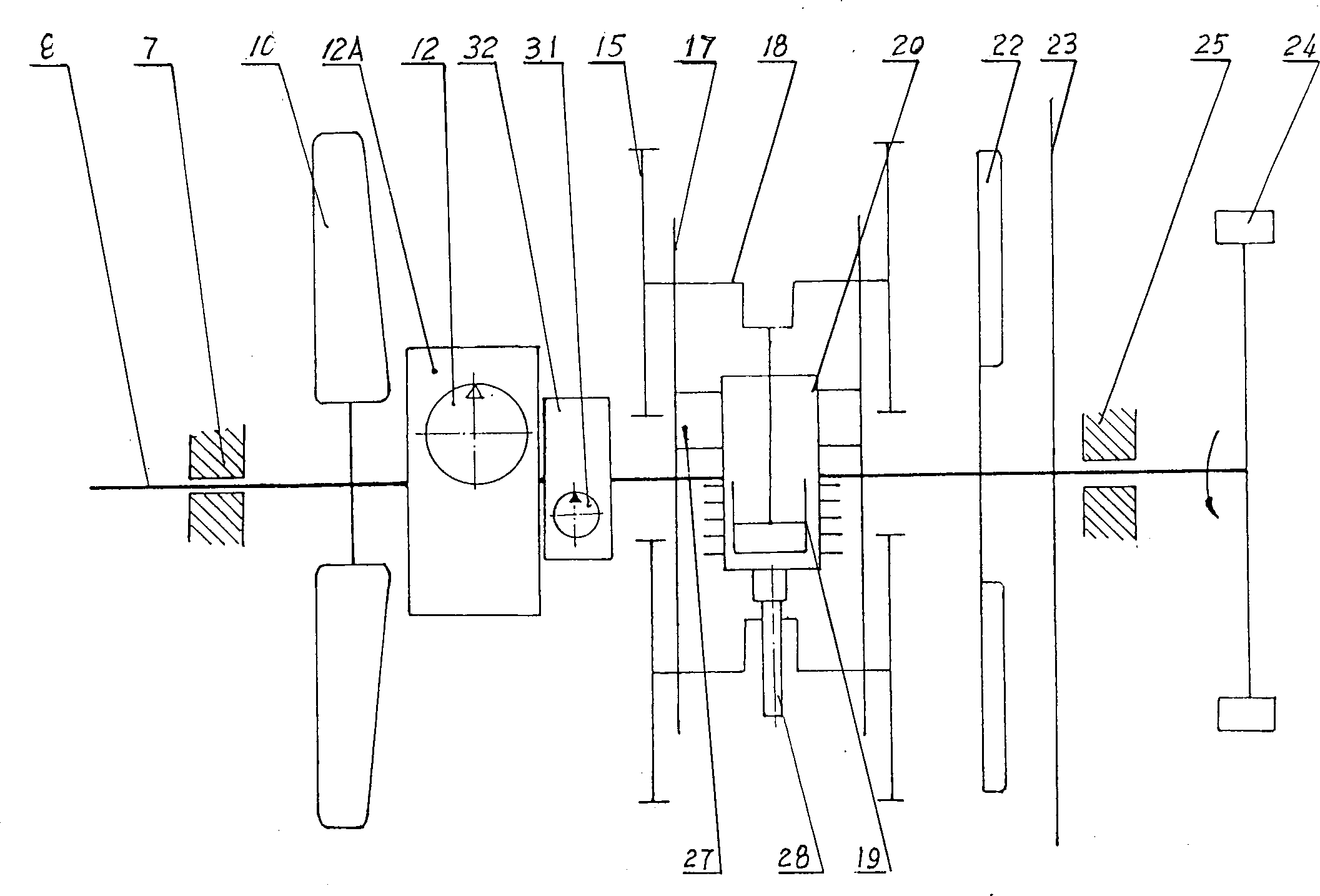

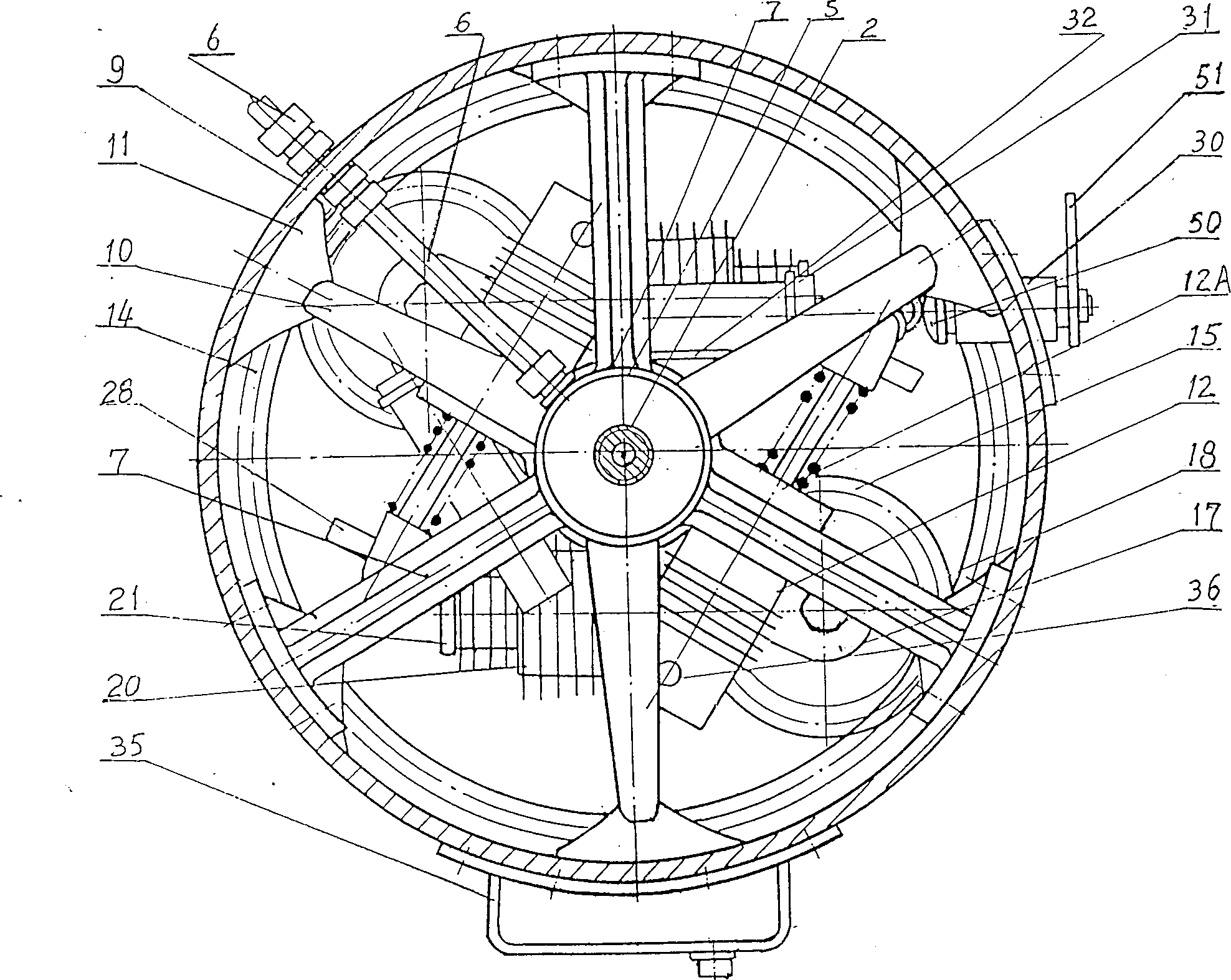

[0037] see figure 1 , 2 3. A direct-push type reciprocating piston internal combustion engine has a cylindrical body 9, a straight line and a hollow main shaft 8 in the front section, and it increases the output power of the main shaft in the following manner: two identical symmetrical ones with The power brackets 16a, 16b of the cantilever 17 are connected to the main shaft 8 by a tooth key through the fixed frame thereon, and there is a certain distance between the two; the lugs on both sides of the cylinder 20 are installed on the power bracket 16 to fix them. on the mounting plate 27 of the rack. The centerline of the cylinder 20 is perpendicular to the centerline of the main shaft, and the distance is S. From the axis center of the main shaft 8 to the hole center length L at the top of the cantilever 17, the crankshaft 18 is housed in the hole. The planetary gears 15a and 15b whose indexing circle is radius R are meshed with the inner gear rings 14a and 14b fixed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com