Equipment capable of intelligently disassembling and assembling truck tail hook frame layer board bolts

A yoke frame and bolt technology is applied in the field of intelligently disassembling and assembling truck yoke frame support plate bolts, which can solve the problems of harsh working environment, high labor intensity, inaccurate torque, etc., so as to improve the working environment and reduce labor intensity. , the effect of precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

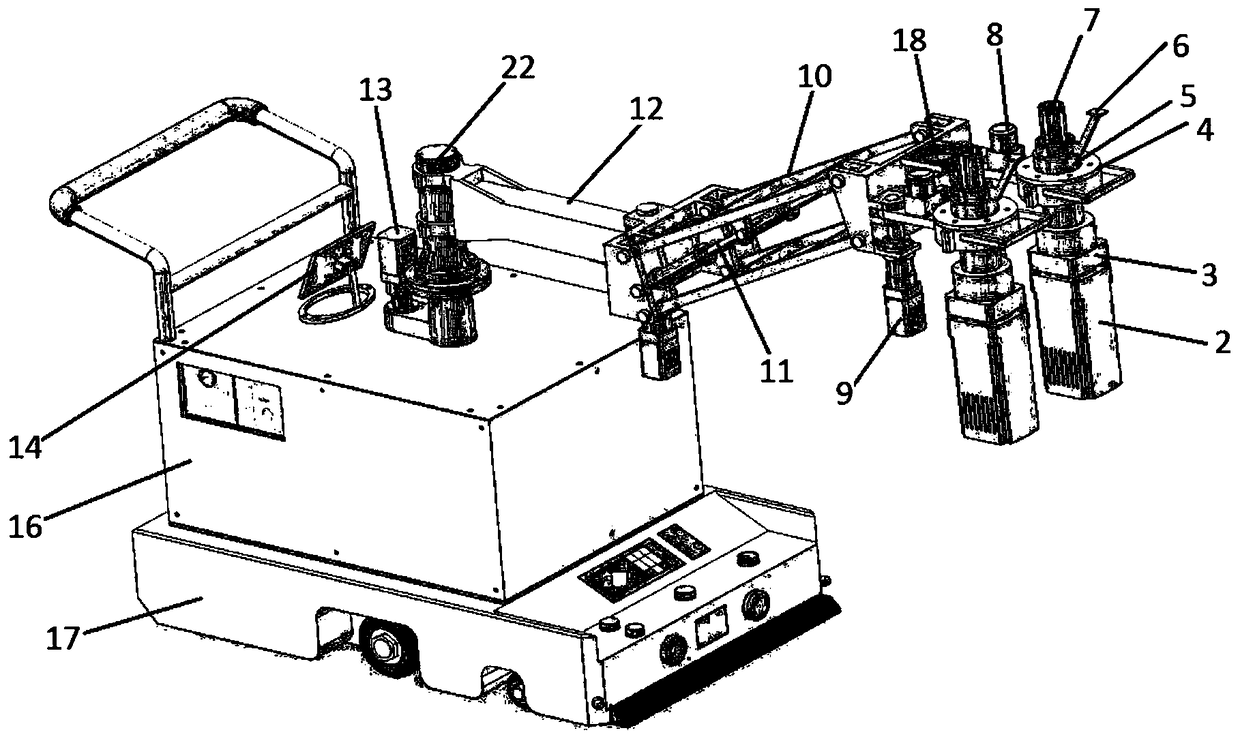

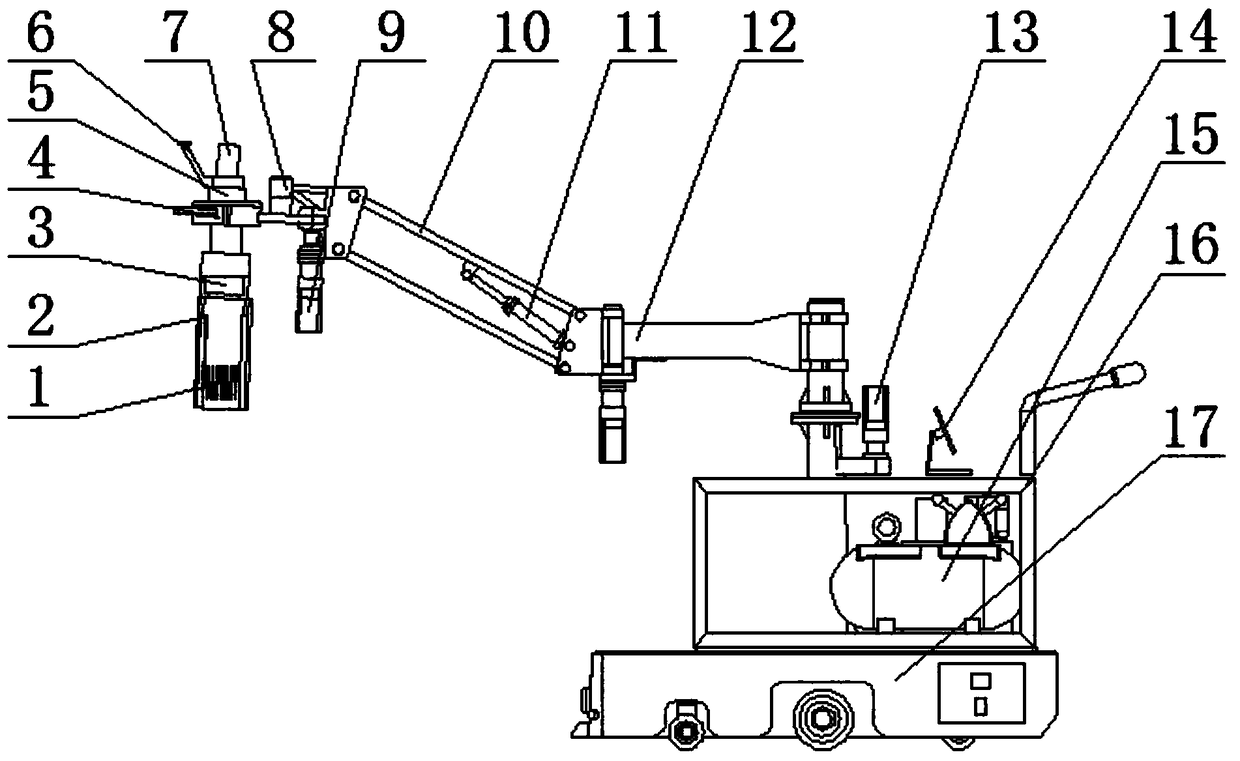

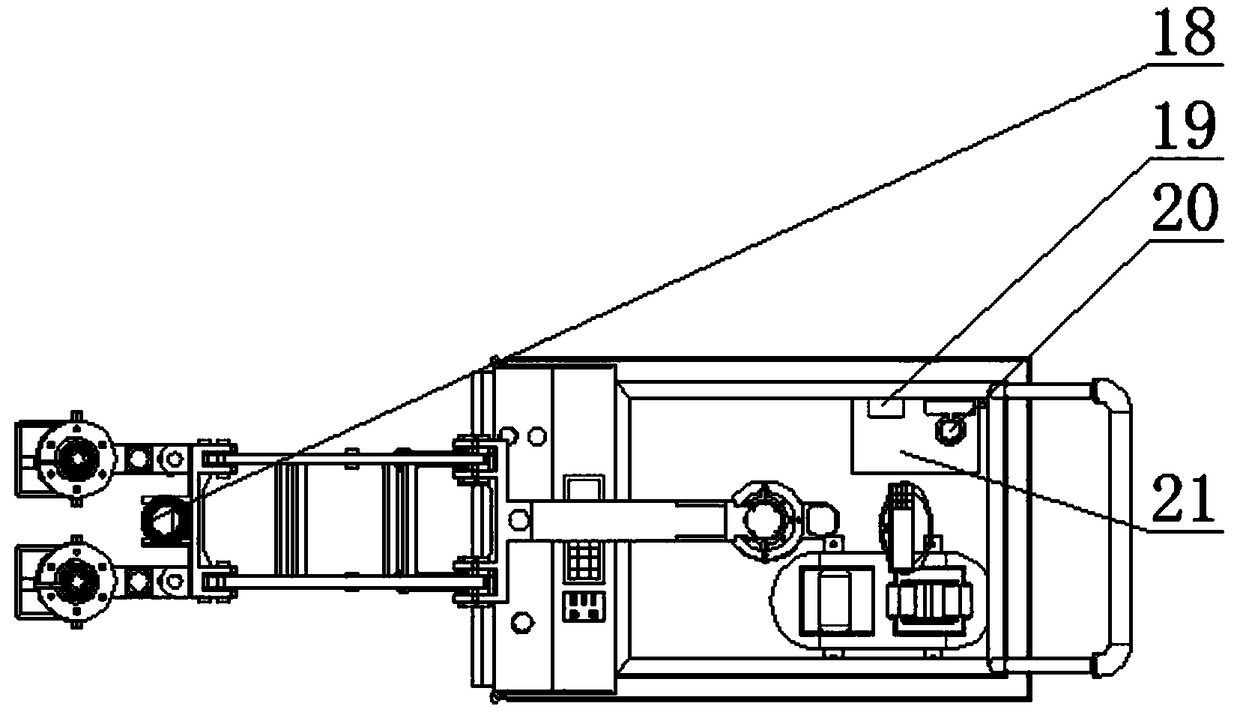

[0027] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0028] see Figure 1 to Figure 3 , the motor 1 is connected with the casing 2 through threads; the torque limiter 3 is connected with the motor 1 through a keyway; the connector 4 is connected with the output shaft of the motor through an interference fit, and connected with the booster arm through a flange; the torque multiplier 5 is connected with the motor output The shaft is connected through interference fit; the reaction arm 6 is connected with the casing 2; the nut sleeve 7 is connected with the motor output shaft through the outer hexagon; the industrial camera 8 is fixed on the connector 4 by bolts; the RV reducer motor 9 is connected by the flange The plate is fixed on the connector 4; the arm 10 is connected to the boom 12 through the balance cylinder 11; the boom 12 is connected to the rotating column 22; the column power system 13 for controlling the rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com